A

A - functional surface; B - the outer surface, visible after installation; B - outer surface, not visible after installation; G - mounting surface, overlapped by spillway or water folding fittings

AND WATER PIPE

Table B1

|

Detail number |

the name of detail |

Quantity |

Material |

|

1 |

Conductor |

1 |

Steel wire with a diameter of at least 5 mm in accordance with GOST 3282 or steel tape in accordance with GOST 503 or GOST 16523 with a thickness of at least 2 mm and a cross section of at least 24 mm2 |

|

2 |

Bolt Mb-6g x 35.58.019 according to GOST 7798 |

2 |

Steel grade not lower than 10 according to GOST 1050 |

|

3 |

Washer 6.0!.08kl019 according to GOST II371 |

4 |

Also |

|

4 |

Nut Mb-6N.5.019 according to GOST 5915 |

2 |

UDC 696.14:006.354 MKS 91.140.70 Zh21 OKP 49 4000

Key words: enameled cast iron sanitary appliances (baths, sinks, trays), technical requirements, marking, packaging, transportation, storage

Editor V.P. Ogurtsov Technical editor N.S. Grishanova Proofreader M.S. Kabashova Computer layout E.N. Martemyanova

Ed. persons. No. 021007 dated 10.08.95. Handed over to the set 11/17/97. Signed for publication on 27.11.97. Uel. oven l. 2.79. Uch.-ed. l. 2.0. Circulation 755 copies. _C1145. Zach. 848._

IPK Standards Publishing House 107076, Moscow, Kolodezny per., 14.

Typed at the Publishing House on a PC

Branch of IPK Publishing house of standards - type. “Moscow printer”, Moscow, Lyalin per., 6.

Plr №080102

Basics of color marking of pipelines in accordance with GOST 14202

The main requirement of GOST 14202 for the marking of pipelines is the identification coloring of pipelines in different colors depending on the transported substance. Correspondence of groups of substances and colors are presented in table 1.

| Table 1 | ||

| Substance being transported | Samples and name of colors of identification coloring | |

| Group number | Name | |

| 1 | Water | Green |

| 2 | Steam | Red |

| 3 | Air | Blue |

| 45 | Combustible gases Non-combustible gases | Yellow |

| 6 | acids | Orange |

| 7 | alkalis | Violet |

| 89 | Flammable liquidsNon-flammable liquids | Brown |

| 10 | Other substances | Grey |

Thus, if the enterprise has a lot of pipelines with different contents, then the color marking of pipelines in accordance with GOST 14202 greatly simplifies the visual perception and understanding of the pipeline diagram.

For example, for the color marking of air ducts, the color color is blue, GOST 14202 provides for contrasting black for blue.

However, the blue color (in its ordinary representation) does not contrast with black. In such a situation, GOST 14202 recommends using a blue color with the addition of white to the paint (in practice it turns out blue).

The situation is similar with the color marking of alkali pipelines - in practice, the violet color acquires a lilac hue.

5 Types and basic dimensions

5.1 Types, main dimensions of reinforcement must correspond to those indicated in Table 1 and in Figures 1-6.

Table 1

|

Siphon type |

Name |

Figure number |

|

BOO |

Bottle siphon unified with outlet and vertical or horizontal outlet for washbasins, sinks, bidets |

1 |

|

SBU2 |

Also. for washbasins and sinks with two bowls |

2 |

|

STU |

Pipe siphon with a unified outlet, horizontal or vertical outlet for washbasins, sinks, bidets |

3 |

|

STU2 |

Also. for a washbasin" and sinks with two bowls |

4 |

|

SVPG |

Siphon with outlet and overflow for bathtubs and deep shower trays |

5 |

|

SPM |

Siphon with outlet for small shower trays |

6 |

|

STUNS |

Pipe siphon with a unified outlet, horizontal or vertical outlet for washbasins, sinks, sinks made of corrugated stainless steel pipe for high-rise buildings |

3 |

The symbol for siphons for use in technical documentation and when ordering should consist of the word "Siphon", the name of the material, the designation of the type of siphon, and for bottle and pipe plastic siphons - additionally the letters "c" or "d" characterizing the type of outlet (vertical or horizontal), and the symbols of this standard.

An example of a symbol for a plastic bottle siphon with a unified outlet and a vertical outlet for washbasins and sinks. bidet manufactured in accordance with the requirements of this standard:

Siphon plastic SBU in GOST 23280-2016

3

GOST 23289-2016

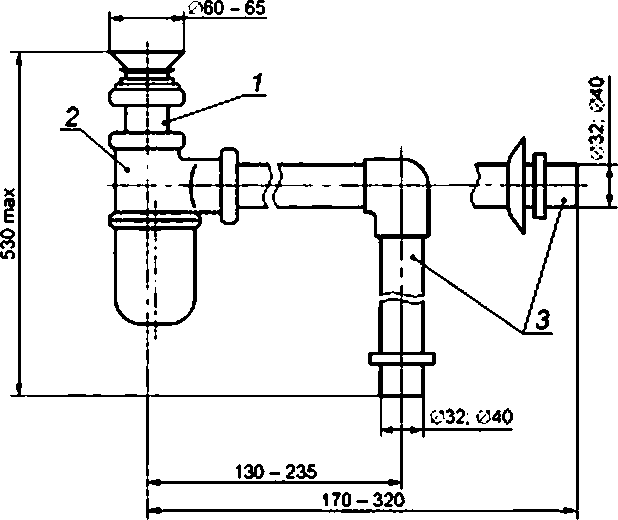

i - release. 2 - siphon body; 2 - branch

Figure 1 - Unified bottle siphon with outlet and vertical or horizontal outlet for washbasins, sinks, bidets (SBU type)

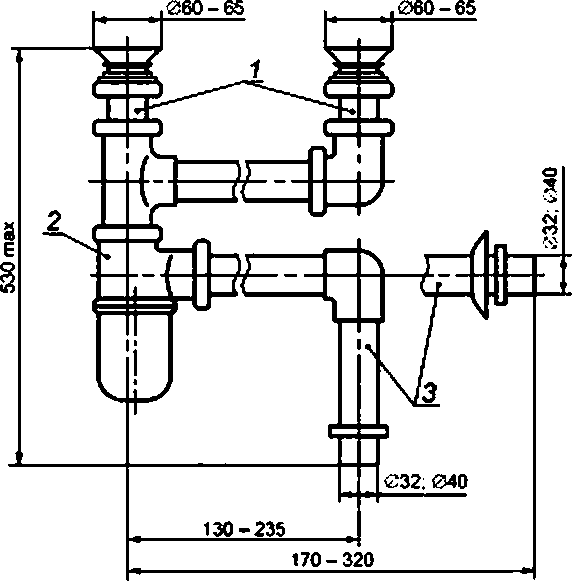

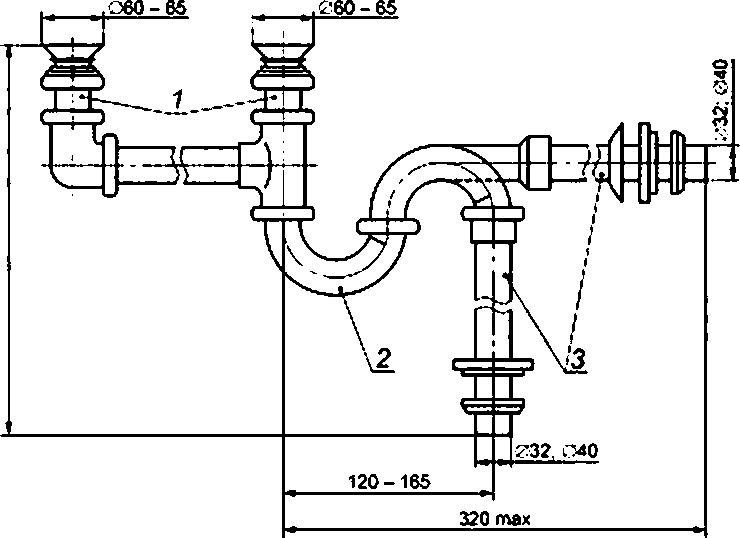

J - release; 2 - siphon body. 3 - branch

Figure 2 - Bottle siphon unified with outlet and vertical

or horizontal outlet for washbasins and sinks with two bowls (type SBU2)

4

530 tech

GOST 23289-2016

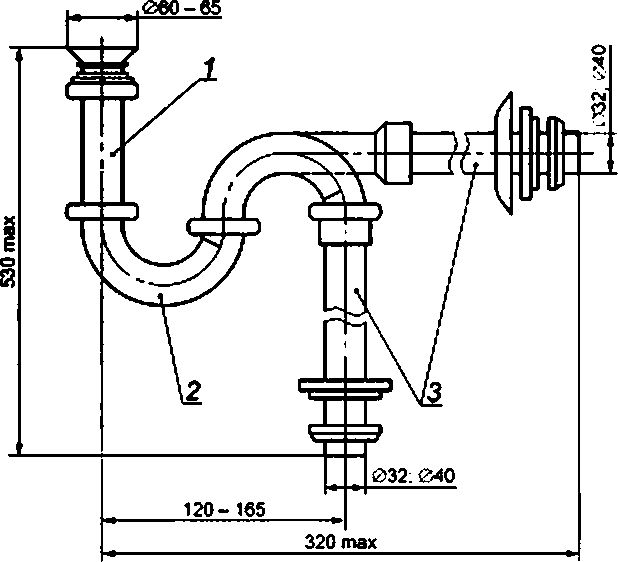

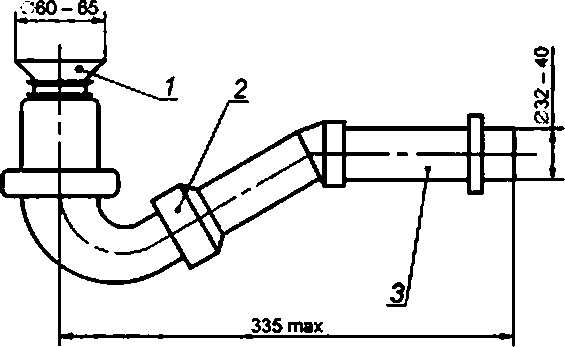

1 - release. 2 - siphon body: 3 - outlet

Figure 3 - Pipe siphon with a unified outlet, vertical or horizontal outlet for washbasins, sinks, bidets (type STU. STUNS)

1 - release; 2 - siphon body: 3 - outlet

Figure 4 - Pipe siphon with a unified outlet, vertical

or horizontal outlet for washbasins and sinks with two bowls (type STU2)

5

GOST 23289-2016

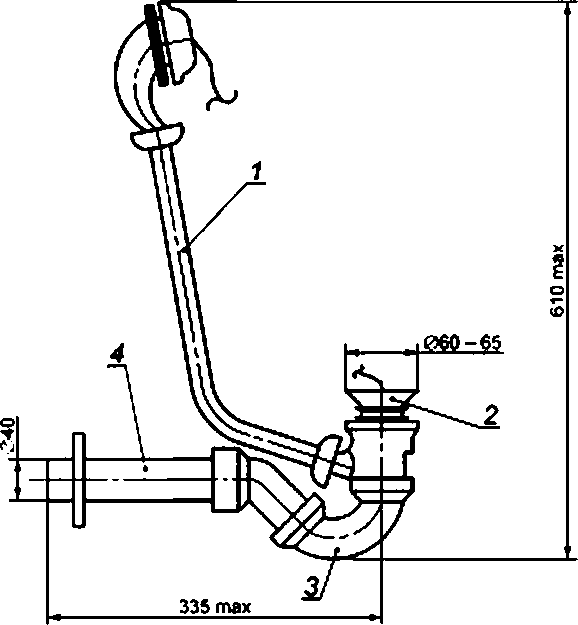

J - overflow: 2 - release. 3 - siphon body: 4 - outlet

Figure 5 - Siphon with outlet and overflow for bathtubs and deep showers

pallets (gyp svg)

1 - release. 2 - siphon body: 3 - outlet Figure 6 - Siphon with outlet for small shower trays (SPM type)

b

GOST 23289-2016

CAST IRON ENAMEL SHOWER TRAYS

TECHNICAL CONDITIONS

GOST 10161-83

Official edition

USSR STATE COMMITTEE FOR CONSTRUCTION

Moscow

DEVELOPED by the Ministry of Building Materials Industry of the USSR

PERFORMERS

O. P. Mikheev, Ph.D. tech. sciences (topic leader); V. I. Gorbunov, Ph.D. tech. sciences; V. I. Feldman, Ph.D. tech. sciences; N. D. Vorontsova; N. F. Zhukova

INTRODUCED by the Ministry of Industry of Building Materials of the USSR

Deputy Minister A. Ya. Anpilov

APPROVED AND INTRODUCED BY Decree of the USSR State Committee for Construction of January 10, 1983 No. 2

UDC 621.648.4:669.13:006.354 Group G21

STATE STANDARD OF THE UNION OF THE SSR

CAST IRON ENAMEL SHOWER TRAYS

GOST

10161-83

Specifications

Cast-iron enameled shower basins. Specifications

Instead

GOST 10161-73

OKP 49 4500

By the Decree of the State Committee of the USSR for Construction Affairs dated January 10, 1983 No. 2, the deadline for the introduction is set

This standard applies to enameled cast iron shower trays (hereinafter referred to as trays) installed in sanitary facilities, public and industrial buildings.

Pallets must meet all the requirements of GOST 18297-80 and this standard.

1.1. Pallets should be manufactured types;

PDCHM 800 — cast iron enamelled shower tray fine

dimensions 800X800 mm (see Fig. 1);

PDCHM 900 — cast iron enamelled shower tray fine

dimensions 900X900 mm (see Fig. 2);

PDCHG 800 is a cast-iron enameled deep shower tray measuring 800 × 800 mm (see drawing 3).

Note. Pallets of the PDCHM 900 type are allowed to be manufactured on January 1, 1985.

1.2. The main dimensions of the pallets must correspond to those indicated in Fig. 1-3, the dimensions of the outlet for the release - in hell. 4.

Limit deviations of dimensions; overall ±5 mm, connecting ±3 mm.

from 01.01.84

Non-compliance with the standard is punishable by law

1. TYPES AND BASIC DIMENSIONS

Official edition

Reprint prohibited

Standards Publishing, 1983

Reference weight of the pallet after enameling 52.5 sh

Reference area of the enamelled surface of the pallet 0.95 m2

Crap. one

Deviations of other dimensions and weight should not exceed those specified in GOST 1855-55 for castings of III accuracy class.

1.3. The symbol for pallets in the technical documentation and when ordering must consist of the word "Pallet", pallet type designations and this standard.

An example of a symbol for a shallow cast-iron enamelled shower tray type PDCHM 800:

Pallet PDCHM 800 GOST 10161-83

Reference weight of the pallet after enameling 60.0 kg. The reference area of the enamelled surface of the pallet is 1.20 m2.

Crap. 2

Dimensions and regulations

- According to what GOST do bathtubs?

Currently, there are four types of plumbing fixtures on the mass market:

- Acrylic;

- steel;

- cast iron;

- Stone (more precisely, from artificial stone - a composite material based on stone chips and synthetic resins).

The types of bathtubs and their sizes are interconnected: they have different regulatory requirements:

- The production of cast iron bathtubs is regulated by GOST number 18297 - 96;

- Steel plumbing fixtures are manufactured in accordance with GOST 23695-94;

- There are no separate documents for acrylic and stone products in the Russian standardization system; they are manufactured according to the technical specifications (TS) agreed with the customer.

Cast iron

- What is the size of a standard cast iron bath produced in accordance with GOST 18297 - 96?

| Model | Length (by size), cm | Width (overall), cm | Bathtub height including legs, cm | Depth (from the edge of the side to the outlet), cm |

| HF-1500 | 150 | 70 | 63 | 40 |

| HF-1600 | 160 | 70 | 63 | 40 |

| HF-1700 | 170 | 75 | 63 | 40 |

| VChP-1700 | 170 | 75 | 63 | 40 |

Steel

- What dimensions of steel baths are provided by GOST 23695-94?

There are only three sizes:

- VST-1500 has a length of 1500 mm, a width of 700 mm, a depth of 380 and a height of 600 mm;

- VST-1600 - 1600x700x380x600;

- VST-1700 - 1700x750x3800x600 millimeters.

Acrylic

- With what dimensions are acrylic devices made?

Manufacturers are absolutely not limited in their imagination and can make a device of any size - there would be a demand. I can only indicate the lower and upper bounds:

- The minimum dimensions of a triangular bathtub are 120x120 cm. The smallest of the rectangular devices produced have a length of 1200 mm. As a rule, a mini-bath is made seated, it is impossible to stretch out in it;

- Bathtubs of large sizes for two can be up to 2 meters long and wide.

Fake diamond

- How big are artificial stone bathtubs?

The maximum size that I met in the price lists of manufacturers is 195x180 centimeters. The minimum is 120x70.

Tile marking learning to read icons on packages

If some interesting tile caught your eye in the store, try to find out from the seller everything related to its purpose and method of production. And so that he does not accidentally mislead you, ask to see the box in which the collection lay. There is always information on the packaging that can tell you why this coating was produced. For example, an outdoor version of the tile will be much stronger than the one you need for the bathroom, and you will have to pay extra for it. And why do you need an expensive option if this strength is absolutely not useful in an apartment where there is no sharp temperature difference and contact with dirty street shoes.

So, consider all the icons and inscriptions that are visible on the box. They will "advise" which tile to choose for the bathroom.

2. Characteristics

4.2.2.

The surfaces of devices are divided into functional (A), visible (B), invisible

outer (V) and mounting (G) specified in the appendix.

4.2.4. enamel

surface coating A and B sinks and sinks should be chemically

resistant to acids.

4.2.5. Impact strength of enamel coating of surfaces A and B

devices should be at least 0.6 J (0.06 kgf × m).

Coefficient

diffuse reflection of the enamel coating should be at least 78%.

Shine

the surface of the enamel coating of devices should be at least 45%.

4.2.7. Depending on the indicators of appearance, the quality of the enamel coating of surfaces A and B

devices are divided into grades: first, second and third in accordance with

table.

grade

devices are accepted according to the quality of the enamel coating of surfaces A and V

and according to the flatness and shape tolerances of these surfaces, according to the lower of the two

ratings.

table 2

Norm per 1 m2 enamelled

instrument surface

First grade

Second grade

third grade

Dark scattered dots with a diameter of 1 to 2 mm

Not allowed in

over

2

4

8

Local translucence of ground enamel on ledges and

sides

General is not allowed

over area, cm2

5

10

20

Pin pricks up to 2 mm in size

Not allowed in

over

2

4

8

Blisters without exposure of metal up to 2 mm in size

Not allowed in

over

—

4

6

Ground enamel exposure up to 15 mm (only for

baths)

General is not allowed

over area, cm2

—

2

3

Fused hair lines

Not allowed

Allowed

inconspicuous

Burnouts

Not

allowed

Enamel sagging

Not

allowed

4.2.10. V

sinks, sinks, bathtubs and pallets of the third grade, enamel spalling is allowed on

surfaces V total area up to 2 cm

with sealing of damaged areas with a protective coating.

4.2.11. enamel

surface coating G appliances

should be smooth, without sagging of enamel.

mopping up

welds are also subject to welding in places where parts are welded to sinks and sinks.

- admission

flatness of the longitudinal and transverse sides of the appliances and the back of the sink - 1.5

mm per 500 mm length;

- admission

flatness of the surface of the bracket adjacent to the wall, for completing

sinks - 2.0 mm;

- shape tolerance

a given surface (corrugations) for walls, sides, bottom and transition radii

sides to the walls: for the first and second grade 0.5 mm, for the third - 0.8 mm.

Bathtubs and trays

must have a horizontal position of the sides; deviation should not exceed 4

mm.

4.2.18. An equalizer of electrical potentials is made from

steel wire with a diameter of at least 5 mm or steel tape with a thickness of at least

2 mm and a cross section of at least 24 mm. The design of the potential equalizer is given in

application.

4.2.19. The electric potential equalizer must have a protective

coating corresponding to the location during operation of category 4.2 according to GOST 15150.

4.2.20. For fixing the electric potential equalizer of the bath and

pallets must have a welded steel plate with a thickness of at least 2 mm

and a cross section of at least 24 mm.

Volume

- How many liters are in a standard cast iron bath?

The longest and widest HF-1700 holds 235 liters. The most compact HF-1500 has a volume in liters of 196.

- What is the volume of steel plumbing fixtures?

There are no direct indications of the volume of the bath in the text of the corresponding GOST and in the accompanying documentation for the devices. However, Mister Common Sense will help us out. The dimensions of the steel VST-1700 correspond to the dimensions of the cast-iron VCh-1700, while its depth is less by 2 centimeters, or 5%. It is logical to assume that the final volume will also be 5% less, that is, 235 * 0.95 = 223.25 liters.

- How to find out the volume of an acrylic or stone bath?

For a rectangular appliance, the useful volume can be roughly calculated by multiplying the distance from the bottom of the overflow hole to the bottom with the length and width of the bowl (do not confuse them with overall dimensions).

A more versatile and accurate solution is to fill the tub once, pouring water in buckets of known volume.

- How many cubes of water according to the counter does it take to fill the bath?

A cubic meter is related to a liter as 1000:1. To calculate the volume in cubes, it is enough to divide the volume in liters by 1000. For the notorious HF-1700, we get a value of 0.235 m3.