Features of the orders of brick ovens

Furnaces often serve as interior decoration, so they are lined with clinker, tiles, tiles. The diagonals in the first row are carefully measured, and a plumb line is hung in the center of the chimney, which is removed on the last rows of the pipe. Also, the diagonals are controlled every 4 rows, and on each row a cord is pulled when laying, which is checked by the rule. Instead of a cement-sand mortar, it is recommended to use clay, regardless of the type of furnace being built. Ready-made dry mortars significantly save time spent on clay preparation. So that the composition does not dry quickly, the brick must be moistened with water before laying.

Operating costs will be less if there are no rectangular ledges inside the structure. To this end, when creating an overlap (ledge), the stone is tried on without mortar, the line of overlap is outlined, and the excess material is cut off with a grinder. Internal seams during laying are regularly monitored, and excess mortar is removed from time to time. The pipe is cleaned after completion of work.

Brick ovens are laid out from several materials:

- outer cladding;

- masonry bricks (main structure);

- fireclay - refractory material lays out places that are subjected to strong heat (furnace, under);

- brick with high density edges - located inside the furnace.

Clay bricks cannot be mixed with fireclay, and ovens, hobs, rods and grates of grates, water tanks are not embedded in the masonry - this is due to different expansion coefficients during heating. If the metal elements are rigidly embedded in the masonry, then the structure will soon collapse.

Benefits of stove heating and its disadvantages

When choosing a stove for home heating or cooking, you must definitely familiarize yourself with the advantages of such functional structures:

- a classic wood-burning stove is assembled quickly enough without the need for large financial costs, provided that the project is properly prepared;

- the universal design is easily combined with a fireplace, bringing special notes of comfort and coziness to the interior arrangement of the living room;

- the possibility of arranging an autonomous heating system that operates without access to centralized and public communications;

- the choice of an inexpensive and most economical type of fuel when selecting a program to reduce energy costs (additional insulation);

- a practical possibility of combining stove and water heating to distribute the coolant over the entire area of \u200b\u200bthe room.

Buslaev oven projects

The design has a built-in hood. The oven is small. It is ideal for any private home, as it allows not only to heat the premises, but also to cook food. Despite its compact size, the stove heats spacious rooms well, so there are ready-made projects of houses with a stove.

Special schemes for laying brick ovens will help you get the job done without complicated calculations.

For installation, you will need the following materials:

- doors - fireboxes (0.2x0.25 meters), VK (0.39x0.5 meters), blower (0.14x0.14 meters);

- refractory - 43 pieces;

- solid brick - 382 pieces;

- oven-cabinet 28x33x50 cm;

- cast iron stove 0.7x0.4 meters with burners (removable rings of different diameters);

- valves - steam exhaust (12x13 centimeters) and smoke (12x25 centimeters);

- grate - grate 30x20 centimeters;

- corner - three blanks of equal-shelf rolled products 1 meter long and 45x45 millimeters in size;

- steel - a piece of 0.3x0.28 meters;

- strip - 4 pieces of meter (4 millimeters), 0.25 meters (2 millimeters), 0.35 meters (3 millimeters);

- cast iron stove - 0.4 x0.25 meters; 40x15 centimeters.

Projects of brick ovens of this type are as follows:

- Complete row.

- The door blew.

- Window opening for cleaning.

- The bottom of the oven is laid out from refractory, three sides are lined with iron.

- Installation of the furnace door, grate, under the furnace - refractory, cleaning cover, blower door.

- DS installation.

- Laying refractory on the edge around the LH.

- Laying according to the scheme.

- The upper coating of the oven with clay (1 centimeter) is carried out, the DT overlaps, a stove with burners is attached.

- Installation of smoke circulation with cleaning windows, the plate is not laid. In the future, the brick is placed on the edge.

- Cleaning is covered, channels are created, 25 cm strips are laid.

- The cleanings are finished, the fixing wire is embedded.

- The cap is installed.

- Installation of the ceiling VK, while the hoods remain.

- The stoves are laid out according to the scheme.

- The small stove ends with sheet iron, the laying is carried out in the order of the brick oven.

- A cleaning hole of a large stove is laid out, the edges of the side walls of the channels are crimped.

- Protrusion masonry.

- The protrusions are duplicated and the corner is mounted.

- The chimney of the BP overlaps similarly to the 19th row.

- A three-row neck is made, the size of the chimney is reduced to a section of 26x13 centimeters for the top valve.

- A chimney with grooves is created on this and subsequent rows.

The dimensions of the structure increase when using clinker facing bricks, so it is not recommended to use them instead of solid material. When finishing with tiles, durability is ensured (the material lasts for decades), in addition, it can be dismantled for facing other heating structures.

Masonry furnace design V. E. Grum-Grzhimailo

Scheme of the furnace designed by V. E. Grum-Grzhimailo

The following figure shows the furnace of the channelless system of Professor V. E. Grum-Grzhimailo. It doesn't have any fluff at all. The design has a round shape and is enclosed in a case made of sheet steel. The gases will move in the furnace not so much under the influence of the draft of the chimney, but under the influence of gravity. As a result, the heavier cooled gases will sink down, and those that are hotter and therefore lighter will rise up.

This device consists of 2 parts. The lower part is occupied by the firebox. In the overlap of the firebox there is a small hail (mouth) to ensure the passage of smoke gases to the upper part. The top is a chamber without smoke circulation. It looks like an overturned cap like a glass. That is why such furnaces are often called bell-type or channelless.

Heated smoke gases will not leave the hail into the chimneys, because they first rise under the ceiling and, cooling down, go down the walls to the very foundation. Here they will fall into the chimney, after which, under the influence of thrust, they will be carried away into the atmosphere.

The vertical A-A cut is made across the firebox, and the B-B cut is made along it. Horizontal cuts are made from rows 1 to 9 of masonry. On section 9-9 you can see the so-called buttresses. In other words, these are vertical ribs (a quarter of a brick) that run along the walls of the stove from the ceiling of the stove to the ceiling of the vault. They will form a packing and be arranged in order to increase the internal surface of heat absorption and better absorb heat from the flue gases by the furnace array. The fins that are heated by the gases can allow the oven to retain heat longer.

The device designed by Grum-Grzhimailo will use about 80% of the heat of the fuel that is burned. The iron case is able to make the walls of the furnace a quarter of a brick thick, and therefore the device is able to heat up quickly enough.

The heating and cooking stove is a two-tiered hood. The lower tier warms up more, which allows you to heat the cold air at the bottom of the room.

The laying of such a design is not at all complicated.The advantage is that if the smoke damper on the pipe is not tightly closed, the furnace, in its upper half, will not be cooled by cold air entering the firebox. The air that enters through the slots in the ash and fuel doors into the firebox will rise through the hail. However, due to the fact that it is heavier than the hot gases of the bell, it will immediately overflow into the side channels and go into the chimney. In this regard, the entire part under the hail (the entire cap) will not be cooled.

The disadvantage of this design is the predominant heating of the upper part. In order to reduce it, it is necessary to arrange holes in the 5th row of masonry in the walls of the firebox. The stove will function well on anthracite and lean bituminous coals. If the structure is fired with firewood (in particular, raw), the gaps between the buttresses will be overgrown with soot.

It is quite difficult to clean the soot, because the cleaning doors are located in the 8th row and do not make it possible to get completely into all the gaps of the buttresses. The smoke will be discharged into the root pipe.

Channelless designs according to the principle of free gas movement are square or rectangular. Can be performed in a metal case or without it. In the latter case, it will be necessary to thicken the walls of the cap to 1/2 brick.

Masonry stoves for home drawings and diagrams

Classic Russian wood-burning stoves for the home have characteristic advantages.

Instead of obsolete, imperfect devices, new, more modern models of heating furnaces are being introduced into life today.

A competent craftsman who introduces new types of similar structures into life should be well aware of all the shortcomings of the old samples that have survived. He must be able to repair or remake them. To do this, he must be familiar with the most common samples of not only new, but also obsolete devices, as well as know their drawings and be able to apply his knowledge in practice.

Furnace masonry with predominant bottom heating

Scheme of the furnace with predominant lower heating: 1 and 3. Drop risers.2. Lifting riser.4. Chimney.5. Cleaning.6. Smoke dampers.

The following figure shows a furnace that has predominantly bottom heating. Its dimensions are 115x56x231 cm. The heat output will be 2640 kcal per hour. According to the smoke exhaust system, this design can be attributed to combined channel stoves with bottom heating.

Flue gases will descend from the firebox, after which they will rise to the ceiling with a riser. From there, 2 parallel moves will go down to the 16th row of masonry. Then they will go to the last riser, which goes into the chimney.

This design is very rational and simple. It is able to provide a fairly good warm-up of the lower part and has a self-regulating movement in 2 channels of the upper part, which can be considered as a cap with a nozzle.

The principle of a gas blizzard allows air to pass through the bottom of the hood (as shown by the dotted line), while not cooling it. This design is simple masonry and can be located in the partition.

The fuel door and the front wall open into the corridor. The device has a tube. It can be operated both on wood and on coal.

Masonry scheme of a two-tier stove for a house

Scheme of a two-tier furnace1. Void.2. Top cap.3. 4. Packed pipe.

The first picture shows a two-tier oven. It consists of two structures that stand one on top of the other. The dimensions of each of the ovens are 165x51x238 cm.

Furnaces for the house are separated by a brick lining with voids in order to be able to lighten the weight and save some bricks.The layout that fills the space between the upper and lower oven will serve as the basis for the first.

The lower and upper furnaces have completely the same design. The smoke circulation system here is channelless. Gases come from the firebox to the top cap, which has a nozzle. The gases, cooling down, descend and, at the level of the bottom of the firebox, go through the liner into the chimney.

The chimney of the lower furnace passes through the upper one; therefore, the heating surface is somewhat smaller in the latter. The upper structure has its own separate chimney. This device is easy to lay, and the gas flow pattern is quite simple. The cleaning of the lower structure should take place through the door in the rear wall. In the side wall - the top. The furnace works at anthracite or coal. Both pipes are equipped with a pair of smoke dampers.

The upper part of the voids in two-tier furnaces is quite often covered with a solid reinforced concrete slab. Overlapping with a slab will contribute to the stability and strength of the entire structure of the array. Masonry of such a volume should be carried out with particular care, because in addition to the fact that the structure must be covered with a slab, its repair is very difficult, which can cause some difficulties.

The chimney of the lower structure must also be carefully laid out. In the event that there are leaks in the masonry, the wall that separates both pipes on the second floor will allow heat to pass from the upper structure even if both smoke dampers are closed.

In a common array, you can combine furnaces of almost any design, which have a square or rectangular shape and work on any type of fuel. Such a system will be a good heater for a country house.

Classic stove and water heating

Standard wood-burning stoves for the home can be combined with a water heating circuit, significantly increasing the performance of such buildings.

This option helps to reduce the disadvantages of stove heating, which is possible due to the use of modern technologies, and is associated with additional benefits:

- a significant increase in the usable heating area;

- ensuring uniform distribution of heat;

- all elements of the furnace are involved in heating;

- after the suspension of the combustion process, heat is retained.

The design of the furnace with water heating is complemented by a heat exchanger that provides heating of the coolant and its efficient circulation.

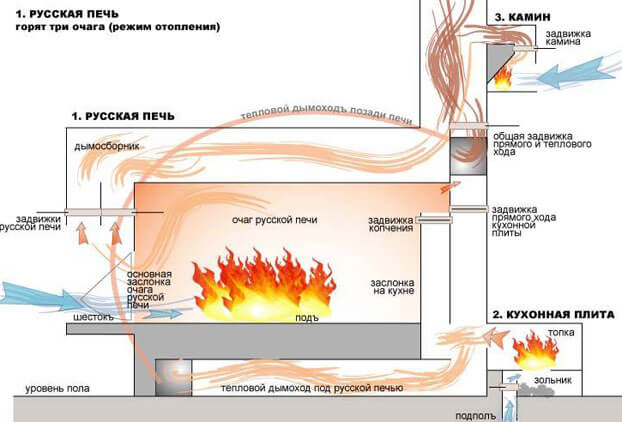

Russian oven drawings of brick ovens

Previously, such designs were found in every home, but now they are already a rarity. Despite this, the Russian stove can successfully fit into the interior of the room. Also, Russian brick ovens are not only a heating device - they also have a hob.

For laying the furnace, the following materials will be required:

To work, you will need the following tools:

- trowel - for laying and leveling the solution;

- pickaxe - a multifunctional hammer with a blade located perpendicular to the axis of the handle. At its other end is a square windshield;

- bubble level for masonry and hydraulic for the first row;

- rule - serves to align the bricks of each row;

- plumb lines - one of them must be permanently attached to the axis of the chimney (overlap), and with the help of the second, the verticality of the corners is checked;

- brush - needed for grouting;

- cord - it is pulled over each row of masonry.

Drawings of brick ovens for any type of house are as follows:

- Cooking chamber. For masonry, a 3/4 ground corner brick with locks is used.

- Under. From the back there is a slope, for the purpose of which the space is covered with sand, on which the brick is laid.

- Covering the bottom. The structure is covered with bricks along bars, corners or sheet blanks.

- Vault with lock.In some cases, a central lock is used, in others, the last two symmetrical bricks.

- Rows to the lower vault. The laying of a brick oven is carried out in the usual way, in the future, a vault template assembled from chipboard or springs cut from wood is installed on top of it.

- Wells. They are tied rows, in which they leave a hole leading to the undercook.

- Underbay. Bricks are laid on foundation mortar, hollow stones are not allowed.

- Code VK. For convenience, the bricks are cut to a wedge shape.

- Covering the channel above the samovar. It is solid, only whole stones are used.

- Holes are reduced above the shestak. The brick is cut in accordance with the drawing.

- Wall alignment. At the same time, the overtube is reduced, the channel of the samovar is laid.

- Installation of a samovar. The structure is closed with a separate cover.

- View installation. To build in the structure, two rows are laid.

- Chimney. The height of the pipe from the bottom to the top must be at least 5 meters. The upper rows form a visor that prevents precipitation from entering the chimney.

Thanks to this stove, high-quality heating of the house is provided.