Clay and ceramic mixtures. clay properties

Clay is the basis for the production of tiles

It consists of oxygen, hydrogen, silicone and aluminum, and when water is added, it changes its structure, becomes more flexible and viscous. When water is removed, the clay hardens and becomes rigid. It is very important to know that clay that has only recently been dug out of the ground is not yet ready to be used as a raw material for pottery. The working qualities of recently mined clay leave much to be desired

The main characteristics of clay that will be important to you are plasticity, firing temperature range and degree of shrinkage.

plasticity of clay

Plasticity allows you to get complex shapes (such as the corners of steps, for example)

If the clay is too plastic, it will not have sufficient strength to make large-shaped objects from it, it will collapse at high temperatures. In this case, coarse-grained materials should be added to it. Clay with a coarse-grained structure will not be plastic enough, it will break when twisted and molded, it will not be possible to obtain the desired shape from it. In order to make it more convenient to work with, add more sticky or more plastic clays to the composition.

The plasticity of clay is easy to determine by eye, squeezing and rolling a lump. You can conduct a simple test - make a sausage out of clay and start bending it in an arc. The smaller the radius of the arc along which the clay bends and does not crack, the more plastic it is. Another simple way to determine plasticity is to break the clay sausage into 2 parts. If the ends of the edges are thin and stretch like threads, the clay is plastic. If the ends are thick and dry, like stumps, and the clay itself crumbles in the hands, it is of low plasticity. Potters call plastic clays fat clays, and low-plasticity clays lean clays.

We repeat that none of these types of clay can be used in its pure form for the preparation of tiles, they will definitely need to be mixed to obtain the material of the desired consistency.

Temperature range of firing clay

Each type of ceramic clay and each added ingredient has its own specific melting point, which determines the firing temperature required to sinter the clay when it is turned into ceramic. A clay mass formula or recipe may include several different clays, as well as other non-clay materials, which are added to obtain a material with certain properties, depending on the purpose of use of the product.

Potters distinguish low-melting clays (with a melting point below 1350 degrees), medium-melting (temperature from 1350 to 1580) and refractory (temperature, you guessed it, above 1580 degrees). The more plastic the clay, the lower the firing temperature it can withstand. To increase the temperature, add fireclay or pumice to the clay (with pumice, the temperature will drop to 800 - 950 degrees).

Clay shrinkage rate

Your piece will change its mass and dimensions during drying and firing as water evaporates from it. When you are going to make tiles that are specifically designed for some limited space, you need to know as much as possible about the degree of shrinkage of this clay.

The greatest shrinkage occurs during firing, when chemically bound water leaves. Further, a continuous process of curing and compression occurs with the formation of glass crystals in the fired clay, which turn the clay mass into ceramics. The higher the firing temperature, the more the clay shrinks. To reduce shrinkage, increase the amount of chamotte in the ceramic mass.

How to avoid cracking and deformation of clay

Whether you succeed or fail in your tile-making venture depends on choosing the right type of clay. One of the most difficult tasks for you will be to avoid cracking and deformation of the products during drying and firing. Fortunately, this task can be made easier if a significant amount of granules or particles of a coarse-grained material, such as fireclay, is added to the clay. Ideally, the amount of chamotte should be between 15 and 40 percent, while it is desirable that the particles be of different sizes.

A good clay mass for tiles should contain 12/2? percent of fireclay fine grinding and 25% - medium grinding. For those who already have experience with ceramic masses, this may seem an extremely large amount (and it is not suitable for making small ceramic figures, where the content of chamotte is unlikely to exceed 20%), but the open pore structure that is obtained due to chamotte, allows the tiles to dry more evenly and avoid warping.

DIY construction process

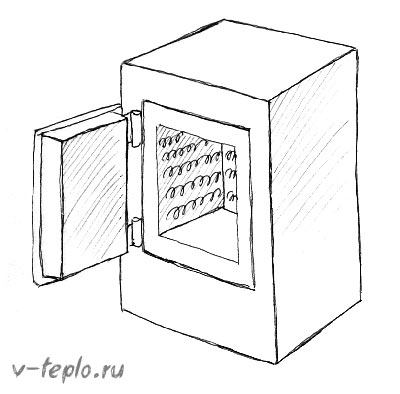

Following the traditions of pottery, craftsmen continue to make their own kilns for firing. So, do-it-yourself dome oven is often found on the territory of workshops and other other options. First of all, it is necessary to prepare the body of the future device. Even a washing machine can act as it, it would be better to say, its body. You can also make the body yourself from a galvanized sheet. In this case, the following dimensions should be adhered to: width - 50 cm, length - 50 cm, height - slightly less than 100 cm.

Next, you need to strengthen the bottom of the box with a corner or pipes that are welded around the perimeter of the base and through the center. It is recommended to make legs with the same pipes. In addition, it does not hurt to strengthen both the rib with hinges for the door and the door itself.

The bottom and walls are covered with 10 mm thick basalt wool, for its safety it is necessary to lay out several pieces of a square pipe and close everything with a metal sheet. Do not be afraid that outwardly the pottery kiln does not resemble the beautiful Duet fireplace stove, because they have completely different functions. Fiber boards and fireclay bricks can serve as refractories. Sealant for fireplaces and stoves in the case of fireclay bricks, it will be represented by a special mixture.

Tightly joined bricks act as masonry, they can be cut to the required size. First of all, the bottom of the body is laid out, the refractory mixture is diluted with water, while cement is also added for the outer layer. Bricks must be soaked in water before laying. Next, the masonry is thrown onto the walls and ceiling. Moving to the top, it is necessary to equip the middle with blocks laid out in a trapezoidal shape. Do not forget that the door must also be lined with bricks. After that, the door is welded, fitted to the size.

This is followed by the laborious process of conducting electric heating coils. Grooves for spirals are formed along the entire perimeter, while the depth of the grooves must correspond to the diameter of the wire. Here, nichrome wire or ready-made spirals from it can be selected. Never allow the coils to touch.

After laying the spirals, its ends must be brought up, then install the ceramic plate from the electric stove and fix the ends with bolts. Next, a coil switch is installed with two contacts on one side and three on the other, and the wires are connected. The pottery kiln is ready, it must be dried and the tiles for stoves and fireplaces laid out

It is important to remember that this stove is dangerous, and you must always be on your guard with it.

Furnace device

The final stage in the creation of a ceramic product is its firing.In this case, pottery kilns serve as indispensable devices. Before you start building your own, or buy a ready-made one, you need to understand the design of this invention. It has a very simple structure:

- Thermally insulated firing chamber made of refractory material

Gas burner, or heating device

loading and unloading device

Control devices

A serious approach to the choice of equipment will ensure the production of quality products. Moreover, not only the design is important, but also related materials, whether it be a mixture for fireplaces and stoves, solutions and other means. All modern furnace equipment is equipped with a software system, thanks to which the furnace for heating or firing has convenient control. With the help of this system, the performance of work can be regulated by dozens of specially set modes, in which it is possible to fire a variety of materials and objects.

Today, the production of bricks and other clay-based materials is a very profitable business. Large enterprises use large-format industrial versions of furnaces, made in a variety of sizes and shapes. (See also: Do-it-yourself tandoor oven)

Of course, for our own production, by the way, a small-sized oven is suitable. Many enterprises today are engaged in the manufacture of devices to order at the request of the consumer. Moreover, this option for purchasing equipment is the most optimal, since the furnace will be made for a specific job.

Now electric ovens are very popular. They have a special welded chamber made of metal profiles. It should not be said that it has high thermal insulation, since there are refractory bricks and various fibrous materials here. Such ovens are characterized by small dimensions. Often such a design is mistaken for a decorative oven, however, this is not so. Its small size is associated with a smaller thickness of the lining. The equipment is equipped with a swing door and high level heating coils. This approach eliminates the possibility of deformation of fired products. The equipment is equipped with a software system and a microprocessor temperature controller.

Pottery kiln manufacturing technology

"Factory" furnaces, especially for professional purposes, are very expensive (over 35,000 rubles), but craftsmen have learned how to make devices for firing with their own hands. It is worth noting that, according to the type of fuel used, such furnaces can be:

We will consider only the first two, since it will be quite difficult to achieve the required temperature by burning wood. Let's start with electrical equipment. According to the location method, these kilns can be:

- muffle (in which the heating elements are located around a sealed vessel (muffle) made of fireclay material; with the help of such furnaces, Russian schools are often heated);

- chamber (the heating device is located inside).

The second option for home-made is more suitable, because it is quite difficult to build a large muffle on your own, and the heat loss of the muffle design is high. Consider how you can make a chamber oven.

How to make tiles yourself Technology Overview

|

||

|

Various types of dry mix and wet clay |

Before starting work, wet clay rests in a bag |

After the clay dries, its color and mass will change. |

In modern factories and factories, tiles are often obtained by pressing and firing dry mass. Huge expensive pressing machines and special furnaces are responsible for this. At home, this is not the best option, so you will need to use wet clay, which you can shape into any shape.

Briefly, the process looks like this: wet clay is taken, it is shaped, it is dried, fired, glazed and fired again (to set the glaze).

Now a little more

Before starting work, wet clay rests in a bag and waits for you to make something out of it. When you start making a tile, it turns into a raw ceramic product. While you are molding the tiles, they will dry out a little, and by the end of the molding they will harden a little. This stage, when the clay is still moist, is called the hard skin stage.

When your tiles are completely dry, you will find that the color of the clay has become lighter. Now we can say that it is at the raw stage. At this point, the tile is already quite hard, but if you hit it lightly, it may crack or crumble. If you leave such a tile to dry outdoors and it is exposed to rain, then the tile may become limp and turn into a lump of clay. There is no need to get upset about this, because such a property of clay is very beneficial. If you make a bad sample, just toss it in a bucket of clay waste and forget about your troubles. Later, when the clay lays down, it can be reworked and made into something new and beautiful.

After all the moisture has evaporated from the clay and the tiles have reached a green state, they are ready to be placed in the kiln and fired. What you do next depends on what glazing technique you use; but in accordance with common practice, during the first firing, which is called biscuit firing, the clay is not specially burned after. Depending on the maturation temperature of the clay, the biscuit firing temperature can range from 850°C to 1000°C. Under these conditions, ceramic products remain porous and are able to easily absorb the glaze.

The second (glaze) firing takes place at the temperature necessary for the maturation of the glaze. This temperature may be lower than—but never higher than—the temperature required for the clay to mature; otherwise, the icing will melt and turn into glassy balls.

Method two. We make a stove without a metal case at hand

The manufacturing process in this case is not much different from that described above, but there are definitely some nuances here. To begin with, the working volume of the design below will be about 13 liters. The spiral, as mentioned above, can warm up to a thousand degrees in just 1.5 hours, while the temperature of the outer walls of the device does not exceed 100 degrees. The algorithm of actions should be as follows.

Step 1. First, using a profile pipe 4x2 centimeters (with a square section), we build a stand for the device. After that, paint the finished stand with enamel.

Step 2. We fix a sheet of galvanized steel on top of the stand (its thickness should be approximately 0.1 cm), using self-tapping screws "for metal".

Step 3 We make the walls from fireclay bricks and a special fireplace composition (everything is the same as in the previous version). After the solution hardens, we make grooves for the spiral.

Step 4. We assemble the bottom from bricks separately, we use the same mortar for fastening. Before continuing work, we wait for the complete drying of the structure. Do not forget to wet each brick immediately before laying.

Step 5. We lay a thermal insulation layer on top of the metal base (we can use the same basalt wool for this). In order to maximize the compaction of this layer, it must be moistened before fixing the brick bottom.

Step 6. We continue the traditional laying of the furnace, but we try to ensure that all voids and seams are carefully filled.

Step 7The cover for the camera is traditionally made of fireclay bricks, but at the same time we fasten them together with a metal screed.

Step 8. We lay the spiral in the prepared grooves, insulate the structure from the outside with thermal insulation material. Next, we close everything with sheets of galvanized steel, which are cut in accordance with the dimensions of the resulting chamber.

As you can see, this requires knowledge not only in the furnace business, but also in the field of electricity. You can see another possible manufacturing method from the video below.

Video - wood burning stove

How to make a Bubafonya oven on your own

Earlier we talked about how to make a Babufonya oven on our own, in addition to this article, we advise you to read this information, see all the details here