How to properly insulate walls with mineral wool

Let's talk first about what can put all your work down the drain.

Errors in mounting mineral wool boards

- Lack of surface preparation. It should be smooth, clean and treated with an antiseptic (if it is a tree).

- Carrying out work during rainfall or leaving the finished work without protection from rain.

- Insufficient adhesive application. It is correct when it is distributed over the entire surface, including around the perimeter. The most suitable adhesive is polyurethane foam or a dry mix. The first product is easier and faster to work with, but a bit more expensive. Both products are weather resistant and guarantee a good grip.

- Unfilled seams between insulation parts. They can only be closed with inserts of the same material. The maximum clearance is 2 mm.

- Intersection of slabs in window and door corners. In these places there should not be a joint.

- Lack of mechanical fasteners. Anchors and dowels are used as additional connections for heavy sheets. The optimal quantity is 3-4 pieces per piece (two in the corners, 1 or 2 in the center).

- Smooth mounting, butt to butt. Masters advise installing elements in a checkerboard pattern - it is easier to avoid gaps in the structure.

These are the main mistakes that people make when making thermal insulation at home on their own.

Instructions for insulating the walls of the house with mineral wool from the outside

You will need a metal profile or beam to create the crate, related tools for building the frame, a knife or saw, fasteners and a membrane film for vapor barrier. There are two methods. Let's consider one of them. The work is carried out in several stages.

- Surface preparation. It is necessary to remove all old layers of plaster and other finishes from it, clean off dirt and mold, carry out processing and remove all irregularities with a primer.

- Frame installation. After the primer dries, mount the guides at a small distance from the facade - approximately 10-15 cm in increments of 60-100 cm, 1-2 cm less than the width of the block or roll.

- A film is placed under the first layer - with a smooth side to the plate and vapor absorbing inside. It is attached with double-sided tape or a stapler.

- The first layer of cotton wool is attached from above. Usually a softer one is chosen so that it hides indentations or bulges if they remain after leveling. Plates are laid from the bottom up, and rolls - from the top down.

- Next, more rigid elements are mounted. For reliability, they can be fixed with a construction stapler or fungal dowels.

- Another layer of vapor barrier is placed on top (the film is not stretched), crate and cladding.

In the case of mounting under the frame, it is important to know in advance the size of the mineral wool insulation for the walls in order to correctly calculate the distance between the profiles

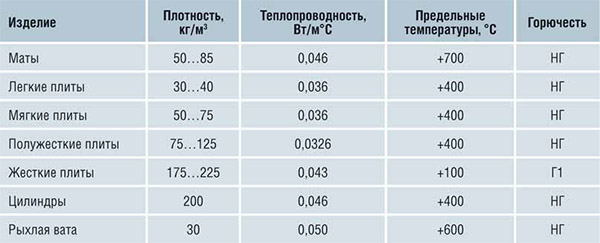

Influence of insulation density on performance

Density affects the following parameters of the material used for wall insulation:

- declared thermal insulation properties;

- sound insulation quality;

- resistance to deformation;

- features of installation in certain conditions of work.

For any heat insulator, there is really a rule: the less it weighs (the lower its density), the more convenient the material for installation, and therefore more preferable. The density factor of stone wool is estimated by experts with a big caveat. Its low thermal conductivity is due to the presence of an air gap between the threads. When this indicator reaches a certain minimum, the material ceases to retain heat.

Effect of Density on Heat Conduction

As a rule, the consumer often pays attention to the performance characteristics of the insulation, rather than physical properties such as density. And you should definitely take it into account, because it carries important information.

Any heat-insulating material contains air either in a rarefied or in its normal state. There is a dependence: the less vapor there is inside the insulation and the worse it is isolated from interaction with the outside air, the higher the thermal conductivity will be. And the larger the latter, the worse the material retains heat.

Wool

Wool insulation is made from lambswool fibers that are either mechanically held together or glued together using 5% to 15% recycled polyester adhesive to form insulating rolls and rolls. Sheep are no longer raised primarily for their wool; however, they must be pruned annually to protect the health of the animal. Wool used to make insulation is wool discarded as waste from other industries due to its color or quality.

Hemp

Hemp fibers are produced from the hemp straw of a hemp plant. Most cannabis is imported, but home-grown crops are on the rise. Because the plants shade the soil, no chemical protection or toxic additives are required for cannabis cultivation. The product is typically 85% hemp fiber with a balloon consisting of polyester bonding and 3-5% soda added for fire resistance.

Therefore, it is necessary to select mineral wool based on the purpose of insulation - for rooms where reliable insulation from the cold is required (living rooms, partitions between floors, floors), denser materials are suitable, and for areas of the house where heat preservation is not so important (non-residential attics , caisson) - lighter slabs or mineral wool rolls

honeycomb glass

Mainly made of recycled glass and mineral base materials such as sand, and without the use of binders. The ingredients are melted into molten glass, which is cooled and ground into a fine powder. Powdered glass is poured into molds and heated in a "sintering" process that causes the particles to stick to each other. A small amount of finely divided carbon black is then added and the material is heated in a "pulp" process.

How to choose the right mineral wool

To begin with, you should pay attention to the permissible scope of use indicated by the manufacturer. If it is a mineral wool for the facade

then it should not be laid on the roof and floor so that it does not lose its characteristics.

In order to prevent the sealing of the insulator and the decrease in thermal conductivity, the insulation must be with an increased density. In order to insulate the inner layer of the roof, it is recommended to use foil insulation so as not to reduce the loss of heat received from the sun.

Mineral wool should have excellent thermal conductivity, so be sure to pay attention to the data indicated on the package

In addition, the service life of the material is of no small importance, and it is desirable that it be more than 10 years.

Mineral wool and its types

Features of mineral wool for insulation

Modern construction cannot be imagined without the use of mineral wool as a heat-insulating material. It has a wide range of uses, which makes it particularly popular among builders. The most common way to use mineral wool is to insulate building structures.

Often mineral wool is used for laying the middle layer. At the same time, the load on the insulation of various types of surfaces in any buildings, houses and structures is avoided.Vertical laying of mineral wool is used to insulate facades and walls. The inclined and horizontal laying method is chosen for the insulation of the ceiling, roof and roof.

What is mineral wool used for?

- For equipping a ventilated façade system, as well as for laying in curtain façades.

- Mineral wool is used to insulate building sandwiches of panels and blocks, which are used to build multilayer walls with different types of cladding. They can be metal, concrete, chipboard, fiberboard and OSB.

- To insulate various industrial buildings, equipment and pipelines.

Modern manufacturers offer consumers different types of general building insulation. Wool can be presented as a light heat and sound insulating material that does not have a coating. Another option: cotton wool with one-sided caching with aluminum foil. Cotton wool can be equipped with a special sound-absorbing material.

Classification of a heat insulator by density level

In most cases, everyone remembers the physics of the school and associates the density of a heat insulator with weight, mass.

The heavier the better, but this does not always follow correctly, based on what factors and what operating conditions.

The selection of a heat insulator depends on the budget, as it does not sound surprising, and of course the load on the structure in general or on a specific component.

According to the density of the material, the following classification is emphasized:

Extra light

These include foamed polymer (expanded polystyrene), has a structure with pores.

Designed for insulation in the voids of walls, partitions, for unloaded components of the house.

Lungs

These are heat insulators based on min. cotton wool. They have a low thermal conductivity. It is widely used in the construction of private cottages and houses.

Medium

In most cases, cellular glass is referred to such types. It has the form of blocks and slabs, with high insulating and soundproofing qualities. It does not have a wide distribution in the Russian Federation.

Tight or hard

They also include mineral wool, tightly pressed under high pressure. This type of heat insulator is used for outdoor work, resistant to moisture and mechanical influences.

Harm to health

Many experts are convinced of the negative impact of mineral wool on health. For the manufacture of mineral wool, manufacturers use phenolic resins, as this provides it with good moisture resistance.

But according to doctors, particles of phenolic resins are capable of releasing harmful substances formaldehyde and phenol. Doctors believe that dust fibers linger in the lungs of a person, causing various diseases.

The greatest danger is caused by particles from 3-5 microns. The binders included in its composition cause serious diseases in people associated with the respiratory system, skin and eyes.

But despite this, most manufacturers do not stop insisting on the safety of the heat-insulating substance. Construction companies also give preference to stone wool, and continue to use it for the construction of new buildings.

Many foreign and Russian companies refuse to use mineral wool at construction sites. This happens because of the wide distribution and low cost, as well as because of the harm that it has on human health.

The characteristics of the material create a favorable environment for rodents, fungus, putrefactive bacteria and mold. Long-term residence in such conditions can develop suffocation, allergic diseases and cough.

Mineral wool has quite diverse characteristics, and has already been subjected to various tests many times. Thanks to the results of the study, manufacturers were able to prove the value of mineral wool in the construction industry.

Despite the shortcomings, the insulation has good thermal insulation, fireproof and has good acoustic qualities. It is often used to insulate building facades, walls, roofs, as well as attics and interior partitions.

Non-combustible substances make it possible to use it as a fireproof insulation, since mineral wool materials effectively prevent the spread of fire and cannot emit harmful toxic substances while on fire. Mineral wool consists of fibers that are inherently water repellent. Special additives significantly increase its quality, it is thanks to the characteristics that it has managed to become world-famous.

Video about the production of mineral wool:

Polystyrene foam labeling

When choosing foam, you need to understand what its marking means:

PS - pressed.

The strength characteristics of such a material are somewhat higher than those of ordinary, but the price is much higher; PSB - non-pressed, suspended. The most common type. Widely used for various heat-insulating works; PSB-S - non-pressing, suspended, self-extinguishing.

It has characteristics similar to PSB, but thanks to special additives it is less combustible; EPS - extruded. Manufactured using a special technology, it significantly exceeds conventional expanded polystyrene in terms of technical characteristics and price. It is expedient to apply for warming of a socle part of facades.

Advantages and disadvantages of mineral wool for wall insulation

Let's sum up a little. The advantages of almost all types of mineral wool include several qualities:

- Fire resistance.

- Easy processing. Plates and rolls are cut with a knife or saw.

- Good sound and heat insulation.

- Easy installation.

- Long service life (from 5 to 50 years, except for slag material).

- The need to work in protective clothing and a respirator.

- Fiberglass may require additional vapor barrier.

There is also an opinion that when heated, the insulation emits vapors that are harmful to health. Manufacturers claim that this is a myth. In addition, after mounting, the layer with thermal insulation is closed with drywall, boards or other finishes.

Particles that enter the air when cutting products can be harmful. To do this, it is recommended to close the respiratory tract, and if the fibers get on the skin, wash them off only with cool or cold water. This is necessary so that the pores do not expand and the cutting dust does not get into them.

All in all, it is a modern, easy-to-use, effective material for protecting the home from high and low temperatures.

Styrofoam thickness

The thickness of the foam insulation has already been discussed in previous articles of our cycle. We have shown that the minimum thickness of the insulation in the first temperature zone of Ukraine, which includes Kiev, is determined by DBN V.2.6-31:2006 "Thermal insulation of the bud", and is equal to 10 cm.

Insulation of a smaller thickness, for example, 5 centimeters, as various teams of "professionals" often suggest, is practically useless to use. In the article “What is the minimum allowable foam thickness for home insulation”, it is mathematically proved that only with a foam plastic thickness of 100 mm does the expected insulation effect occur, and at 140 mm, heat loss through external walls is reduced to zero.

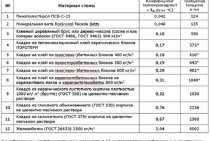

Table 2 coefficient of thermal conductivity of building materials

Name Density, kg/m3 Thermal conductivity* λ W/(m °С) under operating conditions**: A (dry mode) B (normal mode) Structural materials Reinforced concrete 25001.922.04 .10 Foam and gas silicate blocks 1000-3000.36-0.090.37-0.10 Ceramic brick masonry 18000.700.81 Silicate brick masonry 2000-16001.36-0.691.63-0.81 Hollow ceramic brick masonry (gross brick density 1400 kg /m3)16000.630.78Pine,Spruce across (along) the fibers 5000.14 (0.29) 0.18 (0.35) Ordinary glass 25000.76 Double-glazed window 32 4M—10—4M—10-4M0.47 Single-chamber double-glazed window 24 mm 4M—16—4M0.32Roofing material (GOST 10923-82)6000.17Clay tile19000.85Gypsum plaster8000.3Insulating plaster5000.2Steel52Description Density, kg/m3Thermal conductivity* λ W/(m °C) under operating condition**: A (dry mode) B (normal mode) Extruded polystyrene foam26-60 0.0360.034-0.036 Polyurethane foam80-400.05-0.040.05-0.04 Mineral wool pierced mats125-500.046-0.0420.051-0.045 (polyfoam)500.0430.052350.0410.05250.0430.052150.0450.054

*values of the coefficients are taken from appendix A TKP 45-2.04-43-2006, technical specifications from manufacturers of thermal insulation;

** in residential buildings, external enclosing structures refer to operating conditions B, and internal walls, partitions, attic and basement ceilings - to operating mode A.

Thermotechnical calculation of the thickness of thermal insulation and a check for the formation of condensate in the thickness of the structure are carried out by designers individually for each case according to the approved standards for Belarus. The methodology and reference values are given in TCP 45-2.04-43-2006 with current amendments and additions.

The thickness of the insulation depends on:

- outdoor air temperature in winter at the construction site;

- the composition of the insulated structure: what materials are used for the bearing and finishing layers, the thickness and thermal conductivity of each layer;

- type and density of the selected insulation.

The heat-shielding ability of the wall and the heat transfer resistance depend on the thermal conductivity of each building material in the thickness of the structure, the total heat transfer resistance is their sum.

You can calculate what approximate thickness of the insulation is needed for thermal insulation of the outer wall, attic floor, flat roof, floor using an online calculator or on your own - according to the formula for calculating the heat transfer resistance coefficient:

where R is the design heat transfer resistance of the building structure (walls, ceilings, floors, roofs),

δ1, δ2, … δn – thickness, m, 1, 2, … of the nth layer, respectively. The thickness of the thermal insulation is denoted by X and is found from the solution of the inequality. Rounded up.

λ1, λ2,… λn – coefficient of thermal conductivity, W/(m °С), 1, 2, … of the n-th layer, respectively, depends on the type and density of the material (see table 2),

αw = 8.7 W/(m2 °C) – heat transfer from the surface of the structure inside the room,

αn is the heat transfer coefficient of the outer surface:

- for external walls and flat roofs αн = 23 W/(m2 °С),

- for covering the attic, external walls with a ventilated facade αн = 12 W/(m2 °С),

Rnorm is the normative value of the resistance to heat transfer of a building structure:

- for the outer wall Rnorm = 3.2 (m2 °C) / W,

- for a combined coating, attic floor Rnorm = 6.0 (m2 ° С) / W.

According to the calculated thickness, the standard size of the insulation is selected from the catalog of thermal insulation materials.

Warmth for your home!

- Date: 23-02-2015Views: 159Comments: Rating: 17

To increase the thermal resistance of a house or other structure, materials called heaters were invented. To date, there are several types of insulation. All of them differ in the raw materials from which they are made, according to the method of production and purpose.

The methods of carrying out work are primarily influenced by such an indicator as the density of the insulation. The most popular of the heaters are mineral wool, basalt slabs, polystyrene foam and fiberglass. As a rule, these types are used for thermal insulation work on walls, roofs, ceilings and floors.

The density of various types of insulation.

Density of mineral wool

Mineral wool is used as a thermal insulation layer by both professional builders and private individuals when building their own houses. It is a material made from fibers of metal slags and molten rocks.

Its distinctive features are good heat saving characteristics, easy and fast installation, versatility of use, fire safety. It is for these qualities that mineral wool is so loved by builders. To choose the type of mineral wool suitable for insulation, its density should be determined.

What is the density of mineral wool

This indicator characterizes the number of fibers per 1 m3 of material. The mineral wool density index varies from 30 to 300 kg / m3, which directly affects its price. The denser the mineral wool, the more expensive it is. There are more fibers per cubic meter of high-density mineral wool, which affects the consumption of raw materials. That is why manufacturers raise prices.

Specifications related to the density of mineral wool:

- Load resistance. The denser the wool, the more physical stress it can withstand. This rule does not apply to reinforced varieties.

- Preservation of the original form during operation. The denser the layers of mineral wool, the better they retain their original appearance.

- Compressive strength. The lower the density of the material, the more it is pressed through. Mechanical impact on the heat-insulating layer involves the use of high-density mineral wool.

Many believe that the denser the mineral wool, the thicker its layer. In fact, all sheets are of the same thickness, only the number of fibers in each of them is different.

Also, the density of the material does not affect such indicators as:

- vapor barrier

- thermal insulation

- Soundproofing

That is, mineral wool with a density of 100 kg / m3 has the same thermal insulation properties as with 200 kg / m3.

Varieties of mineral wool

The name "mineral wool" combines three varieties. They are distinguished by the raw materials from which the material is made.

- Glass wool. It is based on fibers up to 50 mm long, their thickness is not more than 15 microns. This is the cheapest type of mineral wool. Glass threads give the insulation elasticity and strength. But working with glass wool is inconvenient: it is a fragile material, glass fibers break easily, get on the skin, eyes and respiratory tract. If you mount glass wool with your own hands, be sure to use protective equipment, including glasses.

- Slag. The hygroscopic material, therefore, cannot be used in damp rooms, for finishing water and sewer pipes, for insulating the facade of houses. Production material - blast-furnace production waste, the fibers have a length of about 16 mm, a thickness of not more than 12 microns.

- Stone wool. This is the safest material, as stone threads are strong and do not break. Fiber sizes - length 16 mm, thickness up to 12 microns.

The difference lies in the density and strength of the material. Also, glass, slag and stone wool have different indicators of hygroscopicity, thermal conductivity, and fire safety.

How to apply cotton wool with different densities

By density, four main types of mineral wool can be distinguished.

- Mats. Their density reaches 220 kg / m3, thickness - from 20 to 100 mm. The most durable variety, used for industrial purposes. With their help, they insulate pipes, perform thermal insulation of equipment. For private construction mats are not used.

When choosing the right type of mineral wool, be sure to consider the information from the manufacturer on the package. If you approach the choice of density professionally, then careful calculations are needed to identify the appropriate density of insulation. In practice, the owners of houses under construction choose the density at their discretion, based on previous experience, on the advice of consultants.

Description and influence

Density is a value that is inversely proportional to the porosity of the insulation. Porous materials retain heat and create a kind of buffer.Therefore, a conclusion arises about how density affects: the greater the specific gravity, the lower the thermal insulation properties of the insulator.

illustrative example

For example, birch timber - 500-770 kg / m3, basalt fiber - 50-200 kg / m3. And the coefficient of thermal conductivity of birch is 0.15 W with the same fiber index of 0.03-0.05 W. Thus, porous mineral insulation retains heat almost 5 times more efficiently than denser wooden beams.

It is precisely because of the specific gravity that even thick, reliable walls do not always provide good thermal protection. But a thin layer of insulation can fix this problem. In addition, low specific gravity gives less load on structures: cellular concrete with a low thermal conductivity of 0.1 W is not suitable for insulating thin walls, frame buildings, since its density is almost 400 kg / m3.

Density gives resistance to mechanical stress, so low specific gravity insulators need a protective layer. Such materials include penoizol, polystyrene and penoplex, as well as mineral wool.

Mineral wool dimensions

Manufacturers represent 3 types of mineral wool, each of which has its own type of raw material, namely

3. Basalt mineral wool.

All types are successfully used for hydro and thermal insulation of various residential and industrial buildings. For a more comfortable installation, manufacturers produce products of various sizes and shapes.

Mineral wool rolled up is produced in the form of a large billet, pre-cut and assembled. The dimensions of the material are indicated on the packaging, as they are different for many manufacturers. Thickness can vary from 40 to 200 mm, width from 565 to 610 mm, length about 1170 mm. The thickness of rigid plates for hydro and thermal insulation varies from about 50–170 mm, the width of the product is about 1190 mm, and the length is -1380 mm.

Mineral wool in this format is ideal for thermal insulation of large areas, as the rolls contain a large amount of material. As a rule, the width of the materials varies between 50–200 mm, the length of the sheet is about 7000–14000 mm, and the width is approximately 1200 mm. The material is easy to cut and fit to the size of the room.

Mineral wool in cylinders

Designed for waterproofing hydraulic lines. The basis of this type of mineral wool includes: foil, fiberglass and basalt. The structure withstands high temperatures up to 250 C. The width of the product mainly varies between 12–324 mm, the length is about 1200 mm, and the thickness is 20–80 mm. The exact dimensions are painted on the packaging of the material. Mineral wool in cylinders is intended for thermal insulation of heat exchange systems and heating communications. Diameter, thickness and length are selected in accordance with the size of the pipes

The mass of mineral wool varies depending on the substances filling it

To determine what weight the builder will be dealing with, you should pay attention to the density of the material, which can also be found out as the mass of mineral wool at the rate of 1 cubic meter. This figure can vary from 35 to 100 kg per 1 cubic meter.

The mass of insulation boards is on average 0.6 vkm. In the process of performing technical operations, weight does not play a significant role.

Manufacturers' products have different weights, on average, this figure varies from 37 to 45 kg with dimensions not exceeding 1.35 kg, and depends on the density of the heat-insulating material. Its weight changes significantly with a combined approach to insulation. In this case, the thickness of the insulation used is of decisive importance.

Stone wool has a fibrous structure resembling basalt in composition. It is considered a natural material, 80 percent consists of the earth's crust, and cotton wool itself is made from melts of volcanic rocks.

Balzac fiber is produced in the factory, but its composition is also similar to the chemical structure of rocks. It also contains sand, soda, limestone, borax and dolomite. In finished form, the material has impressive dimensions and is permeated through with air. For storage and transportation, mineral wool is compressed up to a sixfold state.

Many manufacturers are trying to improve the quality of the product by making changes to the composition and production process.To increase rigidity, the plates are stitched, impregnated with bitumen and phenols with the addition of asbestos. If the composition contains additional substances, this may change the characteristics of the product. Bitumen prevents damage by insects and fungus, protects the product from moisture and provides additional strength.

The official standard applies to stone wool made from substances of rocks of the gabbro-basalt group, as well as their identical substances, sedimentary rocks, volcanic, metallurgical residues, industrial silicate slags, alloys intended for the production of heat-insulating, sound-proofing and sound-absorbing materials.

Stone wool can be used as a heat-insulating substance in the construction industry and industrial production for surface finishing with a temperature regime of -180 C to +700 C.

Mineral wool features

Glass mineral wool, with a relatively small thickness and weight, has increased elasticity due to the structure of especially long strong fibers. It is convenient to isolate uneven surfaces, pipes, equipment of complex configuration with Izover, Knauf and Ursa insulation. You can buy glass wool at a lower price than stone. The disadvantage of sand-based insulation is high hygroscopicity and inevitable shrinkage during operation. Glass wool insulation requires the use of protective equipment against sharp fragments that form during cutting.

Basalt mineral wool thermal insulation, according to reviews of homeowners and developers, meets the requirements of energy saving, fire and technical safety standards during installation and operation. The thinner and more elastic fibers of stone wool prevent shrinkage and deformation throughout the entire service life. The protective layer does not allow moisture to pass into the canvas, but does not impair its vapor permeability. The cost of basalt insulation is slightly higher than glass, which is offset by the safety and durability of thermal insulation.

General characteristics of mineral wool:

| The foundation | Thermal conductivity, W/m K | Vapor permeability, mg/m2hPa | Density, kg/m3 |

| glass | 0,03–0,046 | 0,5–0,55 | 13–130 |

| Basalt | 0,035–0,039 | 0,25–0,35 | 30–220 |

Conclusion

The choice of thermal insulation is an important stage of construction. To choose the right material, you need to consider the following factors:

- type of work (internal or external); method of installation of insulation (horizontal or vertical); load on the heat-insulating material; whether it is used for sound insulation; average temperature in the cold season, etc.

It is important to take into account not only the pressure of the mass per unit volume, but also the structure of the insulation, the features of its manufacture and application. An important role is also played by how the thermal insulation material wears out over time.

Mineral wool, for example, tends to absorb moisture, which leads to a gradual increase in thermal conductivity. It also crumbles and crumbles, which makes it thinner at the top.

An important role is also played by how the thermal insulation material wears out over time. Mineral wool, for example, tends to absorb moisture, which leads to a gradual increase in thermal conductivity. It also crumbles and crumbles, which makes it thinner at the top.

The room to be insulated also affects the choice of material. So, for outbuildings, it is not enough to choose a heat-insulating material with a high density. It is necessary to install one that will not be destroyed by small rodents and insects.

As you can see, the density indicator is an important criterion when choosing a heater, but not decisive.

And yesterday and today, mineral wool is one of the most popular heaters, both among private developers and professional builders.Such popularity is due to excellent heat-saving and fire-fighting properties, as well as ease of installation and a wide range of possibilities.

However, in order to use mineral wool correctly and with the greatest efficiency, it is necessary to understand its characteristics. In this regard, the most important indicator is the density of mineral wool, on which its thermal insulation qualities depend.