Ceiling height in a private house

The height determines the convenience of the room in a private house and the way it is operated. The volume of circulating air depends on it.

Minimum Height

Safety standards provide for a minimum ceiling height of 2.4 m for a private house. In this case, it is allowed to install gas appliances: stove, boiler and column

This is also important from a practical point of view. Chandeliers are installed on the ceiling, and at a lower height, it is uncomfortable for a person with a height above 1.7 m to move around

The psychological factor is taken into account: low height depresses, and causes panic in people with a fear of confined spaces. It introduces a restriction on the use of suspended structures and finishes.

Optimal ceiling height in a private house

The optimal height for a ceiling in a private house is considered to be 2.5-2.7 m with a decorative finish. There are no restrictions on choosing a larger indicator, since a small area in this case looks more profitable. This takes into account:

- service method;

- space heating;

- harmony.

Floor cleaning will require a stable ladder. Replacing lamps in spotlights will be difficult. A large height negatively affects the comfort of the room, which is taken into account when choosing the finish and how the room is used. Heating costs will increase. To maintain a comfortable temperature of 22 ° under the ceiling, the air will have to be heated to 30 ° and above. Heat losses through the ceiling increase, which leads to icing of the roof, the appearance of rot and fungus on the rafter system.

If necessary, a ceiling of 3 m and above, the issue of heating is solved by installing a warm water or electric floor. In this case, the surface is heated evenly and the air, rising, warms the entire volume of the room. In private houses with a second light, where the ceiling is at roof level, convection heaters are not used. They are replaced by infrared or the above option with the floor.

Important! For private houses with convection water or electric heating, ceilings are not made higher than 2.7 m.

This is interesting: Gluing polystyrene foam to concrete: dismantling from all sides

Beam type ceilings

By design, all floors are divided into two types: beam and slab. Each of them has certain characteristics.

Beam ceilings are often found in private homes

Therefore, if you need to make your own ceiling base, you should pay attention to this type of construction. The basis of such an overlap is wooden beams, which are based on the bearing walls of buildings.

Their cross section depends on the distance between them, the planned load and the width of the span.

Before proceeding with the creation of the floor, it is necessary to select the wood for the beams. They are made from both softwood and hardwood materials, but the wood must be thoroughly dried for at least 3-4 months. Before laying the beams, they must be checked for the presence of rot, cracks and other defects. If they are found, the material cannot be used.

Beams laid on the walls are aligned along the plane. To do this, parts of tarred boards of various thicknesses are placed under their ends. Raw wooden wedges must not be used to level the beams. The joints between the elements on the inner walls are reinforced with clamps or brackets. Instead of a metal clamp, overlays from boards with a thickness of more than 40 millimeters are also used.

According to fire safety requirements, the distance between the beams and the chimney must be at least 40 centimeters.When sealing the ends into the walls, they are impregnated with an antiseptic, tarred and wrapped in roofing material. This helps protect the wood from rot.

To ensure the rigidity of the floor, every second beam is fixed on the load-bearing wall. Experts advise for this purpose to use steel anchors built into the masonry. To create a draft ceiling on the beams, cranial bars are used. They are attached to the sides of the base, and roll plates are nailed to them, forming a coating.

In addition to wooden beams, metal products are also used. They are smaller and make it possible to save on the total volume that covers the floor. At the same time, metal elements have a greater bearing capacity, which exceeds the figure for wooden beams several times.

But metal beams also have disadvantages. These include susceptibility to corrosion and the inability to create effective sound insulation.

How to choose floor slabs, in detail on the video:

metal cover

Metal floor beams are made from low-alloy or carbon steel.

Metal beams are more durable than wooden beams and have a longer service life. Due to their strength, you can save space by reducing the thickness of the floor itself. It is worth noting that the floor using metal beams is used extremely rarely, more often builders stop at a wooden floor.

The openings between the beams are filled with a mixture of lightweight concrete or wooden shields. By weight, one square m of such an overlap exceeds 400 kg.

With the help of metal beams with your own hands, you can block spans of large sizes, from four meters or more. Metal roofing is a non-combustible material and exhibits a high degree of resistance to various biological factors such as rot or termites.

The disadvantages of this overlap include the tendency to form corrosion in places with a high level of humidity. The overlap of such material has low sound and heat insulation properties. This situation can be corrected if the ends of the beams are wrapped with felt.

In most cases, a rolled profile is used as a bearing element: corners, I-beam, channel. During installation work, reinforced concrete slabs up to nine centimeters thick are laid between the beams. A layer of reinforced concrete screed and slag is applied on top.

For this type of overlap, the following materials will be needed:

- metal beams;

- precast concrete slabs;

- plaster mesh;

- waterproofing materials;

- boardwalk.

In rare cases, reinforced concrete beams are used to cover a private house. Their disadvantage is that the work cannot be done by hand. A mandatory point is the use of lifting equipment.

Two options for ceiling insulation. Pros and cons

Do-it-yourself ceiling insulation in a private house can be done in two ways - from inside the room or outside (from the attic side). Consider them from the positive and negative sides.

Application of different materials

When insulating from the inside, mineral wool is selected, and almost any heaters offered on the building materials market are suitable for the external method.

Inter-beam insulation

The height of the floors in the house

For interior work, installation of a suspension system is required. It is also worth starting from personal feelings, whether a material similar to glass wool is suitable for you in the room, and how it will fit into the format of the room. For external work, this factor can be ignored.

The complexity of the work

Not every person will be able to insulate the ceiling in a private house without professional skills. This is especially true for the suspended structure, which must be not only reliable, but also aesthetically attractive.And external insulation will require less effort and is much easier to perform.

Budget planning

There are times when the laying of floor slabs in a house is crooked. The most relevant way to hide this misunderstanding is to create a false ceiling, which will lead to additional costs. For external insulation, any material for a smaller amount is suitable, for example, foam plastic, expanded clay or other similar materials. Let's consider some of them in more detail.

Assembly of hydro and vapor barrier

First you need to decide what the room will be used for, if there is another heated room on top, then there is no point in installing heat and sound insulation on the draft ceiling, wooden surfaces spread noise and heat quite well.

The vapor barrier is mounted along the entire perimeter of the ceiling, it is especially well stretched in the corners, it lays with an overlap, the boards are mounted along the overlaps. This will help protect the rough base and wooden ceiling from rotting and mold.

Ceiling vapor barrier - effective and high quality

The subtleties of laying insulation

If the insulation is not laid correctly, skirting boards and decor can be destroyed, the draft ceiling can even cause a fire, for which you should slowly study the instructions so as not to confuse the sides, because the markings of different companies may contradict each other.

It is enough to cut circles of about 20 cm in the material around the planned lamp, this will create good fire safety, which is extremely important for a wooden house, and wooden decor elements. It is important to establish these places even during the installation of the material - we measure the places from the wall, then put a mark on top, in the form of a circle with a diameter of 20 cm

Comprehensive thermal insulation reduces the energy loss of the building

The same applies to vapor barrier, although the material is strong enough, but unstable to high temperatures, it can melt and cause a fire, especially if the rough, cladding and decor are made with untreated clapboard. Thus, an underlined design can lead to sad consequences for the interior and the integrity of the room.

But since the lamps and decor are not mounted to the draft ceiling, like the wiring, it is enough from below, at the attachment points, to install heat-reflecting foil on the vapor barrier, squares of 20 by 20 cm. It will not be visible, but it will help preserve the interior of the room and not damage the plan decor design.

Installation of thermal insulation in a wooden ceiling

As we see a wooden ceiling with our own hands, it is quite possible to do it quickly and efficiently. In addition, you can hem the rough base yourself, faster, better than many workers.

Fixing the ceiling when the attic is cold

When the building is one-story, and only the roof is on top, the ceiling installation in a private house is performed as follows.

Step one - filing the ceiling . This requires a shield of boards. The material for it are ordinary edged or tongue-and-groove boards having a thickness of 25 millimeters or more. They are fastened "in the thrust" with long nails, leaving minimal gaps. Tongue-and-groove boards are hemmed with a groove from the wall, from which the installation of a cold ceiling starts.

When deciding what to make a ceiling in a private house from, you can opt for filing it in another way - with plywood or OSB, at least 15 millimeters thick (read: "Plywood ceiling sheathing"). But it should be borne in mind that in terms of one "square" this option is much more expensive and the possibility of the structure sagging under its own weight and the weight of the insulation increases.

As an alternative, in private houses of old construction, a board shield can be placed not below the beams, but laid on top of them. Thus, the height of the rooms will not be reduced, and the living space will not decrease. If necessary, you can make a crate.You should not worry about the appearance of the rough floor, since the fine finishing of the ceiling in a private house will cover the surface, and the beams, painted in the right color, will decorate the interior of the room.

Step two - vapor barrier of the floor . First of all, you should take care of the vapor barrier. On the one hand, this layer should not allow the heat-insulating material to become damp, and on the other hand, it should reduce heat loss due to radiation. This can be achieved with aluminum foil. Also, foil insulation based on foamed polyethylene is used as a vapor barrier - this relatively recent vapor barrier material for the ceiling creates an obstacle to heat loss, due to both radiation and convection. When a chimney is laid in the ceiling, there must be a distance of at least 30 centimeters between the chimney and combustible material.

Step three - floor insulation . The installation of a ceiling in a private house with a cold attic involves the use of heaters, the choice of which is huge (read: "How to insulate the attic of a private house").

The most popular among them are:

- Mineral wool . This material (see photo) is non-combustible, has excellent thermal insulation qualities, but over time they begin to deteriorate. The fact is that even absolutely dry mineral wool begins to cake after a certain period. If the vapor barrier was not done with high quality, this insulation gains moisture and ceases to perform its function. It is impossible not to mention such a lack of mineral wool as the presence of volatile small fibers that irritate the respiratory system. Therefore, they must be isolated from the living quarters very carefully. The cost of mineral wool is democratic. When insulating the ceiling with mineral wool in a private house, it must be handled with care and not tamped, because the thicker the layer, the better the thermal insulation.

- Basalt wool . The ceiling in a country house is often insulated with this type of mineral wool. But there is a difference between these two materials. Basalt wool retains its shape better and practically does not cake, but, unfortunately, it can gain moisture.

Styrofoam . This thermal insulation material is combustible. Disputes continue regarding the allocation of styrene to them. Although the foam intended for insulation must comply with environmental standards, in reality this indicator depends on the manufacturer. As for the heat-insulating properties, this material is excellent, since there are practically no heat losses due to air convection inside the foam layer (read: “How to insulate the ceiling from the inside in a private house“). This insulation does not change its shape and dimensions - even after 10 years, the volume of foam sheets between the beams will not change from the moment they are laid. The material is considered non-hygroscopic and moisture resistant. It is believed that its use allows you not to do vapor barrier at all. But thermal insulation using polystyrene foam is an expensive pleasure and is not available to many consumers.

The choice of materials for the ceiling

What materials the finishing ceiling is made of has already been described. To create a ceiling structure in private homes, as a rule, wood is used.

Here, as in the case of the floor, it is not necessary to pay attention only to the strength properties of the material. For the ceiling, it is better to choose light boards with an attractive texture.

Coniferous species, as well as maple and birch, meet this requirement.

The main parameter when choosing wood is its class and grade:

- Grade A is a selected grade without defects visible to the eye with a smooth surface, which may have a small number of knots inside.

- Class B of the first grade - wood with minor defects, noticeable only upon detailed examination.

- Class C of the second grade with a rough surface and knots. There may be cracks in the boards.

- Class D third grade. Such material is of such low quality that it cannot be chosen as the basis for the ceiling in any case.

If the budget is strictly limited, it is not necessary to purchase a selected variety of wood. You can completely get by with class C wood, but with its preliminary treatment with antiseptic solutions and a tinting composition. This will help to significantly increase the service life.

The variant of wood and its quantity are chosen with an emphasis on the type of ceiling surface that will be made in a private house. So, for the simplest hemming, boards and timber are required. At the same time, the width of the boards allows you to change the design of the ceiling. The wider they are, the rougher the finished surface looks. This allows you to get a unique rustic atmosphere in any room.

The beam is chosen with such a section that is suitable for each specific case. So, if an additional insulating layer is required, then it is worth turning to larger options so that the insulation can easily fit inside.

Important! Instead of hemmed boards, moisture-resistant plywood sheets can be used. But such a design of the ceiling in the house will require a fine finish.

Beam ceiling mounting technology

If you want to figure out how to make a ceiling in a private house, the installation sequence below will help you understand the features of the work.

Tools and materials for work

Before you make a ceiling in a wooden house, prepare the following materials and tools:

- saw or jigsaw;

- hammer;

- stapler;

- screwdriver;

- cranial bars (used if the ceiling is hemmed above the bottom of the beams, the section of the bars is 5x5 cm);

- self-tapping screws (optimal length 4.5-5.5 cm);

- slats for the manufacture of a supporting frame for sheathing from plywood and other boards;

- lining material;

- nails;

- building level;

- thermal insulation material;

- hydro and vapor barrier.

Vapor barrier installation

Before you make the ceiling in the house, a vapor barrier membrane is laid. It is attached with a stapler to the supporting beams from the bottom side.

For these purposes, the following materials are used:

- foil products;

- polypropylene films;

- reinforced polyethylene films;

- multilayer membranes.

Strips of vapor barrier material are attached with an overlap of adjacent elements to a width of 15 cm. The joints must be sealed with adhesive tape. To protect the film from damage, fixing is done through a strip of thick paper. The vapor barrier is brought onto the walls to a height of 20-30 cm. All junctions are carefully isolated.

Insulation laying

After laying the film on the back side (between the floor beams), insulation is laid.

The following materials are used as a heat insulator:

- mineral wool;

- expanded polystyrene;

- Styrofoam;

- basalt wool;

- sawdust;

- expanded clay.

Only light materials (building wool, polystyrene and expanded polystyrene) can be laid on the vapor barrier membrane before the installation of the draft ceiling. Loose insulation is poured into the gap between the beams after the installation of the draft ceiling.

Draft ceiling installation

When making a ceiling with your own hands in a private house, do not forget to mount a rough ceiling surface. It will be the basis for the finishing layer. In some cases, the rough base is used without finishing as a finishing coat.

Installation of a rough ceiling surface takes place in the following sequence:

- We attach a frame of wooden slats to the supporting beams over the vapor barrier layer. It will be the basis for the draft ceiling and support for the thermal insulation material, which is best laid after the frame is made. We make the crate from slats with a section of 3x4 cm. We attach the slats to the beams in increments of 50 cm.For fastening we use screws or nails. The frame will simultaneously act as a ventilation gap between the floor itself and the ceiling sheet.

- After that, we fix the selected material for the manufacture of a draft ceiling. We attach plywood or ceiling slabs butt to joint so that the joining points fall in the middle of the crate lath. We fix the plates to the frame with self-tapping screws, which we screw in with a step of 150 mm.

- The evenness of the surface is periodically checked using the building level.

After completing the construction of a wooden house from a bar, one has to deal with this situation - I want to see a reliable rough foundation from above, instead of wooden beams to implement the intended design, decor installation and spectacular interior. For filing the ceiling, I did not have to hire craftsmen, it is enough to follow the generally accepted rules to make a wooden ceiling with my own hands reliable for many years.

Wooden beams are used mainly in private houses, in apartments - concrete floors. But it is quite possible to make a beam structure during the overhaul of the roof on the top floor, this is better than creating a concrete partition.

Wooden beams are used mainly in private houses.

Operation of floors

If beams with a large margin of safety were used in the structure, laid with a small step, then such an overlap will not need to be repaired for a long time. But still, you need to check the beams for strength regularly!

If the beams are damaged by insects or as a result of waterlogging, they are strengthened. To do this, the weakened beam is removed, replaced with a new one, or reinforced with strong boards.

I have been thinking about repairing the ceiling on my outbuilding in my summer cottage for a long time, but my hands still can’t reach it. But here you need to seriously understand - I didn’t quite understand how the beam load is calculated if there are additional loads. It will be necessary to seriously deal with this, most likely in the summer.

Nikolai, without special knowledge in the field of construction, you will not be able to correctly calculate the load on the beam. Too many factors and nuances need to be taken into account in the calculations. Believe me, it is practically impossible for a non-specialist to do this. To begin with, try to at least determine the type and characteristics of the beam ceilings on your outbuilding. Even if you succeed, then at the stage of rendering the work will stall: the formulas are too complicated (even their simplified versions). My advice: entrust the repair to professionals.

Good day. There is a wooden house, with the first floor and the floor, everything is clear to me. Let's probably put a tarket or something like that. Second floor only beams. The question arose for me: do I need to lay any films? The house is residential, the second floor is residential. Or I’ll shove the insulation between the beams (since it remains, well, like sound insulation), and on top I’ll type the floor, a board of 35mm. It seems, as it seems to me, no films are needed.

General knowledge does not give an understanding of the approximate calculations of the load of the beam / floor. Sofa + cabinet + table + 6 chairs, well, 10 people = about one and a half tons - this is not a load. it's another matter if you decide to place a brick warehouse on this floor. )

- How to lay tiles in the bathroom - step by step instructions for laying

- Do-it-yourself laminate flooring: rules and an example of step-by-step work

- Installation of OSB boards - features of laying on a wooden and concrete base

Floor renovation video

We have compiled a huge collection of video tutorials on repairing and laying floors

A collection of photographs with floor design options and flooring examples

Amplification methods

Beams can be reinforced with steel plates

Steel Auxiliary Materials

Strengthen the wooden beams will help steel plates, fixed on different sides of the bar.Steel tools must be treated with a solution that prevents the appearance of corrosion, otherwise they will be short-lived.

CFRP

The material, which is also called carbon fiber, is a modern technology in the construction world and is actively used during beam ceiling reconstructions. It comes in the form of plates, ribbons or threads.

This plastic material is applied in several layers on the wood surface, providing ease of work and reliable quality, which makes it quite popular.

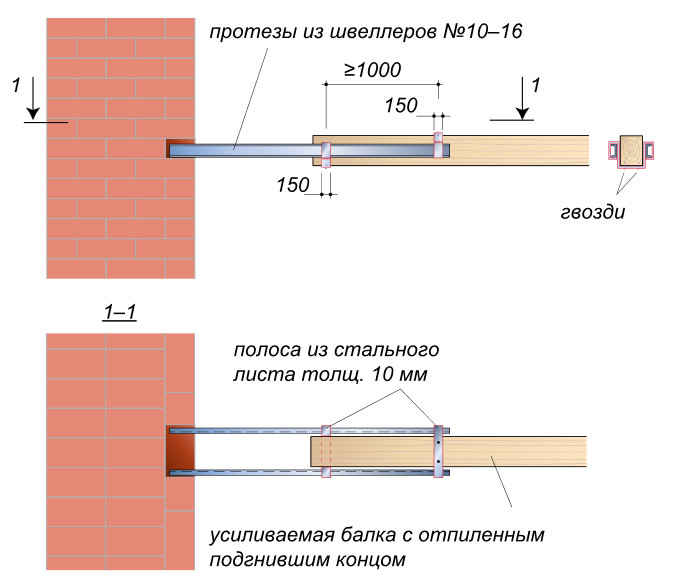

Prostheses made of wood or metal in the butt areas

Due to fluctuating temperatures, the beams in the area of the load-bearing wall are significantly weakened. It is necessary to make the main timber beam stronger in order to prevent negative consequences in the future, as well as to avoid re-reconstruction in the near future.

To do this, additional prostheses made of metal or wood are attached to the edges of the wooden base, which are placed in the brick recess of the wall, thereby providing reliable protection for the central beam.

Installation of prostheses for a rotten floor beam

Supports for load-bearing beams

This method involves placing additional support structures under the ceiling beams to distribute the load evenly.

Additional beams

If the work is done, and the weight is distributed incorrectly, then the finished structure must be covered with additional beams that will take on the excess weight.

Bring to life the ceiling do-it-yourself coverings it is quite possible, but for this you need to familiarize yourself with the necessary information in order to minimize unpleasant moments during work, as well as build a high-quality model that will last for many years.

Ceiling insulation technology

Ceiling finish. experts recommend starting its insulation with vapor barrier measures

It is important to do everything right, observing the sequence of laying the film, the insulation layer. There are two ways of fastening these materials: rack, and, lighter, therefore, popular - using a construction stapler

Thermal and waterproofing will be the more effective, the greater the technical characteristics of heat and steam conductivity will be possessed by the components selected as the main insulation. Mineral wool would be an ideal option - its ability to retain heat is several times higher compared to other types of insulation materials (polystyrene, expanded clay, fiberglass, etc.)

Regardless of which insulation method is chosen, in the frame ceiling, the insulation layer must lie flush with the beams. In this case, it is possible to avoid the occurrence of an additional power load on the wooden structure, and the subsequent external decoration with decorative materials will lie flat.

Thermal insulation should be laid with extreme care in the area of \u200b\u200bthe chimney, especially if its exit in a private house is provided through the attic. In this case, all fire safety rules and regulations must be observed, since the temperature inside the chimney can be quite high and provoke a fire.