What are acoustic mineral wool mats

The technology for the production of acoustic mineral wool boards has some differences from the technology for the production of heat-insulating mats. For example, sound insulation with Amigran acoustic mineral wool demonstrates a remarkable effect, since this material is made from special granular hydrophobized mineral wool and starch binder.

The material obtained in this way has a density of 300 to 400 kg/m3 with a sound absorption coefficient of 0.7-0.9.

Mineral wool soundproofing "Akminit" is manufactured using a more complex, semi-moist technology, which significantly increases its performance, such as strength and resistance to deformation.

Acoustic mineral wool for soundproofing from a Finnish manufacturer (“Acusto-Pop” and “Acousto-Melody”) are also manufactured using a “wet” technology with vacuum, by analogy with the technology for manufacturing fiberboards.

This technology allows for maximum sound and noise insulation, a long period of operation and fire safety.

Soundproofing mineral wool "Shumanet BM" is considered one of the most effective building materials in this regard. This is ensured by the excellent acoustic and consumer characteristics of Shumanet BM.

This material is widely used as a special layer in the construction of frame partitions, wall cladding with sheet plasterboard, chipboard, for suspended ceilings and acoustic screens.

Sound-absorbing slab Shumanet BM, made of mineral wool, is considered the most effective building material for heat and sound insulation.

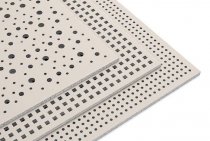

This type of mineral wool is widely used as a special layer when creating soundproof frame partitions, when facing walls with sheets of plasterboard, chipboard, for suspended ceilings or acoustic perforated screens.

Soundproofing: polystyrene or mineral wool?

Myth one. Styrofoam is an excellent soundproofing and sound-absorbing insulation. As you know, foam plastic is produced and sold in sheets of various thicknesses and densities. Different manufacturers call their product differently, but, nevertheless, all this is polystyrene foam (expanded polystyrene).

Styrofoam is a wonderful heat insulator that has nothing to do with sound and noise insulation. The only construction where it can affect the noise is laying under the screed, the so-called "floating" floor. Yes, and this only applies to "shock" noise.

At the same time, the efficiency of a 40-50 mm expanded polystyrene layer does not exceed the efficiency of other types of sound insulators with a thickness of only 3-5 mm.

Myth two. The use of mineral or glass wool slabs in frame construction is more than enough to provide a high level of sound and noise insulation between adjacent rooms.

Indeed, special acoustic mats made of acoustic mineral wool will provide sound insulation of frame partitions by 5 to 8 decibels. The use of arbitrary heaters will lead to much less efficiency, or no sound-reducing effect at all.

Thus, choosing mineral wool as a sound and noise insulator, you make the absolutely right choice. However, acoustic mineral wool should be used not just like that, but in combination with special “acoustic” enclosing structures and special “acoustic” fasteners.

Noise types. Noise Reduction Index

There are several types of noise that can be grouped into two groups:

- Airborne noise. These are sounds that are carried through the air: screams, conversation, laughter, music.Such noise comes from neighbors through small gaps and cracks in walls and ceilings, as well as through open windows;

- Impact noise. These are sounds that are carried along hard floors and walls. Otherwise, shock noises are also called vibrations. Such sounds are especially irritating and unpleasant: perforator drilling; subwoofer; slamming doors; stomp; jumping.

To measure airborne or impact sound, special equipment is required. There are various models of such devices: from professional expensive ones to household ones with quite affordable prices up to 2000 rubles. Regardless of the cost, the principle of operation of noise measuring instruments is the same. Converting vibrations of the trapping membrane into electric current. The greater the amplitude of oscillations, the more amperes are generated. The final data is displayed on the scoreboard.

The upper noise threshold for this time should not exceed 55 dB, which is comparable to the volume level of a typewriter or light clapping of the palm on the table. At night in residential buildings, the upper sound threshold is set at 40 dB, but the recommended noise level is 20-25 dB (whisper volume).

Often these requirements are not achievable. And often not because of someone's malicious intent, but because of the features of the house: thin walls, thin partitions, through holes for electrical boxes and sockets, and much more. If the vibration insulation in the house does not meet the desired, then the best solution would be to install special soundproof structures or materials.

Materials for sound insulation must be selected based on how high-quality sound insulation of walls is required. Preference, ceteris paribus, is usually given to those materials whose sound insulation index is higher. Sound insulation coefficient, sound insulation index or index impact noise reduction - this is a qualitative indicator that reflects how many dB the impact noise transmitted through walls and ceilings will be reduced.