Anti-noise materials

Anti-noise materials according to the type of action can be divided into two types:

- sound-absorbing;

- soundproof pads.

Sound-absorbing - with a large number of interconnected pores that trap and "extinguish" the sound wave. These include all mineral wools, including glass wool, wood fiber boards, porous plastic boards with a cellular structure (polyurethane foam, polystyrene), plaster mortars with porous fillers (perlite, expanded clay, vermiculite, pumice). These materials vary in hardness. Soft are produced in rolls and mats, semi-rigid and rigid in the form of plates (Akminit, Akmigran, Traverton, etc.). The thickness of these materials is not more than 2 cm.

Soundproof gaskets - dampen sound waves due to the elasticity of their own skeleton and air in the pores. Are issued in the form of plates and rolls. These include fibreboard, mineral wool and glass fiber rolls and boards up to 4 cm thick, as well as boards and rolls made of flexible gas-filled plastics (polyurethane foam, polyvinyl chloride foam, latex).

Not too heavy and environmentally friendly anti-noise materials are suitable for use in apartments. Rigid sound-absorbing boards are not suitable due to their weight - their weight is up to 400 kg/m3. In apartments, priority should be given to rolled soft materials or semi-rigid mats.

Basalt wool, foam glass, cork, polyurethane foam have good soundproofing properties, moreover, according to environmental standards, they can be used in residential premises.

Noise-absorbing suspended ceilings

The easiest way to isolate the ceiling from extraneous noise is to install a suspended acoustic plasterboard ceiling. Such material in itself is a good sound insulator, however, in order to increase its effectiveness, mineral or basalt wool mats are laid in the metal frame of the suspension system.

You can also use glass wool in the space behind the suspended ceiling, in any case, these materials will reliably block extraneous noise.

If you plan to install a stretch ceiling, then in this case it is reasonable to use plates made of basalt fiber or polyurethane foam. They are fixed to the existing base of the false ceiling with special plastic "fungi". On average there are 5 pieces. on one plate.

After the acoustic ceiling slabs are laid, the ceiling fabric is stretched onto the baguette fixed to the walls. As a ceiling cloth, it is recommended to use materials with microperforation. It will allow the soundproof layer to "breathe" and will not allow water vapor to accumulate in the insulator.

In order to save the space of the room as much as possible after the installation of stretch ceilings, cork wood slabs can be glued to the ceiling. Ceiling acoustic panels are glued butt-to-butt on a pre-prepared surface with a special adhesive. Such tiles have low sound transmission with a thickness of only 5 mm. Such soundproofing options can also be used for slatted and cassette ceilings.

Soundproof ceilings ARMSTRONG

Armstrong Acoustic Ceilings are a lightweight aluminum alloy frame into which sound-absorbing panels are mounted. They are made of mineral fiber and have a porous structure. On the front side, the panels are covered with a decorative layer - this is the Armstrong suspended ceiling technology standard.

The slabs often measure 600 x 600 mm and are only 1.5-2 cm thick. Acoustic ceiling panels have a sound absorption coefficient of 35 dB, which allows you to completely protect the ceiling from the penetration of extraneous noise. The low weight of the slab makes it much easier to install them in a suspended frame.

Armstrong acoustic ceilings are on a par with other well-known soundproof ceilings. An example is the ECOFON ceiling. The soundproofing panels of this system are made of glass wool and have excellent moisture resistance and low sound transmission.

The boards can be mounted on both open, semi-open and closed fixtures for suspended ceilings or systems. At the same time, such a ceiling has high thermal insulation. Particularly popular are suspended acoustic ceilings from the Danish company Rockwool. Basalt wool is used as the material for the acoustic panels of the ROQFON ceiling.

Conclusion

In order to ensure the coziness and comfort of any room, it is necessary not only to develop a convenient and beautiful design, but also to protect yourself from external irritants. Perhaps this article will help you determine which acoustic ceiling is right for you.

Types of ceiling speakers

On sale there are various types of acoustic systems for installation on the ceiling. Let's take a closer look at the features and characteristics of each type.

Acoustic chandeliers

If heavy overall devices are used, then installing speakers in a stretch ceiling is not possible. In this case, it is advisable to use acoustic chandeliers. The speakers are mounted a short distance from the base ceiling. Acoustic devices are built into the body of the chandelier, which has an attractive modern design. Included with it are special fasteners for installation.

Acoustic chandeliers can be installed indoors with high ceilings and in public areas. It is advisable to mount them in trading floors, rooms with domed ceilings and rooms with a second light.

Outboard speakers

Devices are mounted on a flat surface. Their lightweight streamlined body will fit well into the interior of any room. These speakers can be installed on false and suspended ceilings.

Built-in speakers

Built-in speakers come in open and closed types. The closed version is mounted in a special case, and the open speakers come without a case. The latest devices are designed for embedding in suspended, hemmed and stretch ceilings.

If open acoustic devices are installed, then the ceiling needs soundproofing. This is necessary to protect the space above the ceiling from sound distortion and resonance.

The speaker has built-in step switches that allow you to adjust the sound of the unit to suit the characteristics of the room. Emitters can be rotated at a given angle and adjust their power. The speaker itself is closed with a decorative grille to match the color of the ceiling finish.

Acoustic stretch ceilings

Different types of stretch acoustic ceilings have a different degree of sound absorption. The main parameters of the acoustic stretch ceiling are:

- perforation hole diameter;

- distance between holes;

- panel thickness;

- the interval between the main ceiling and the stretch ceiling.

Materials for acoustic stretch ceilings

For the manufacture of stretch ceilings used:

- Polyvinyl chloride film, which, in turn, is:

- glossy, reflecting light and having more than a hundred tones and shades;

- matte, not giving glare, but quite well reflecting light;

- satin, having an iridescent mother-of-pearl sheen;

- textured, imitating the texture of some material. Drawing a photo or a pattern is possible.

2. Fabric with polyester backing:

- different matte texture;

- We have a less rich color range.

Types of acoustic stretch ceilings

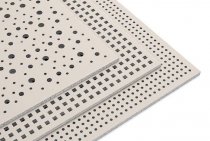

There are 3 types of perforated stretch ceilings:

-

-

- microperforated;

- medium perforated;

- coarsely perforated.

-

What are the parameters to choose an acoustic stretch ceiling

- For an ordinary apartment, it is better to choose finely perforated canvases.

- For a room where a home theater is equipped, maximum sound absorption is necessary. It is achieved by mounting an additional structure made of sound-absorbing material under the suspended acoustic ceiling.

- To create the effect of a starry sky, medium and large-perforated panels are chosen.

If we compare prices for acoustic ceilings, then canvases from well-known manufacturers will cost more, but they will last much longer. Yes, and they look much more elegant.

Acoustic ceiling Clipso

The CLIPSO acoustic ceiling is part of an acoustic ceiling system that consists of:

-

-

- actual stretch ceiling Klipso;

- fastening structure - baguette Clipso;

- mineral sound-absorbing boards.

-

The Clipso stretch ceiling, produced by the Swiss company CLIPSO AG, is a coating that is a sound-absorbing membrane in the form of a seamless breathable CLIPSO fabric with perforation. This fabric:

-

-

- made on the basis of polyester;

- impregnated with polyurethane on both sides;

- colored with environmentally friendly dyes, which eliminates the release of toxins. A drawing or photo printing is applied to the canvas.

-

Advantages of the Clipso ceiling

-

-

- has a canvas width of more than 5 m, so there are no seams on the ceiling in a room of the appropriate dimensions;

- the Klipso stretch ceiling hides electrical wiring, pipes, building structures;

- is a reliable protection against leaks and noise;

- retains heat;

- does not collect condensate;

- easy to clean;

- antistatic;

- does not support combustion;

- mounted by cold installation method;

- creates a perfectly flat surface;

- not susceptible to mechanical damage;

- makes it possible to create an exclusive interior by selecting any image;

- has a long warranty period of 10 years.

-

This acoustic ceiling absorbs medium and high frequencies well. In a room with such a ceiling, there is no sound echo, so it is comfortable:

-

-

- listen to music;

- watch movies in home theater.

-

Clipso acoustic ceilings are suitable for:

-

-

- pools;

- offices;

- music studios.

-

Buying acoustic ceilings is not a problem. The main thing is not to do it spontaneously. Decide in advance on the choice of the type of ceiling, with the manufacturer, select a color that matches the overall design. Listen and read reviews about different acoustic ceilings. Only in this way will your ceiling not only fulfill its main function - to protect you from annoying sounds from the outside, but also make the design of your apartment unique.

In conclusion, watch a video on how the sound insulation of stretch ceilings increases:

Suspended ceilings

Plasterboard ceilings can also be acoustic if they are perforated. It is these holes in the plates that dampen the sound energy. Such a ceiling is a slab with the following parameters:

- dimensions - 595 × 595 mm;

- thickness - 8.5 mm;

- perforation occupies from 9 to 15% of the sheet area.

Benefits of acoustic plasterboard ceilings

In favor of ceilings of this type says them:

- fire safety;

- easy installation;

- resistance to mechanical stress and temperature extremes;

- many possibilities for design;

- ease of care.

There is a wide variety of acoustic suspended ceilings on the market. They differ:

- ceiling system options;

- material;

- execution - from the simplest to the designer.

Types of acoustic coatings and the principle of operation

Acoustic ceilings are suspended and stretch. To improve the sound-absorbing characteristics of the coating, microscopic holes are made in it.

Noise suppression in the room occurs according to the following principle:

- The sound wave, passing through small holes in the coating, is repeatedly refracted and weakened, which helps to reduce the sound level.

- There is air in the perforation of the ceiling, which creates resistance to the flow of the sound wave, due to which its strength weakens.

- There is always air in the ceiling space. The air layer reduces the passage of sound waves from the room to building structures.

Today, several manufacturers produce soundproof ceiling coverings. As for suspension systems, these are Ecophon and Armstrong ceilings. Acoustic tension coatings are produced by two world-famous manufacturers - Cerutti and Clipso. Let's examine in detail the characteristics, pros and cons of each ceiling.

Ecophon acoustic ceilings

The Swedish company E-phon (Ekofon) is known in many countries of the world as a reliable high-quality manufacturer. Ecophon acoustic ceilings are produced in the Saint-Gobain factory.

Ceiling construction

They are similar in design to Armstrong acoustic ceilings. Consist of:

- frame;

- plates.

This is where the similarities end, because:

1. The frame profile has a T-shaped section. Suspension systems for Ecophon acoustic ceilings are:

- closed;

- open;

- half closed.

2. Plates are multilayer, slow-burning, moisture resistant. Manufactured by thermal pressing. They are based on dense fiberglass with the addition of a binding synthetic component. The top of the slab is made of textile, on which a special mesh is laid, which gives the structure a special increased resistance to impacts. The advantage is that the lining of the plate is painted in any color.

3. A standard plate has dimensions of 60x60 or 60x120 cm and a thickness of 1.5 to 4 cm.

It should be noted that Ecophon is the only manufacturer that produces ceiling elements that can take on different shapes and bend.

Soundproofing methods

Soundproofing material is either attached directly to the base ceiling, or laid on top of the false ceiling.

Suspended structures

Suspended ceilings made of plasterboard and plastic need different degrees of noise protection.

Drywall itself is a fairly good insulating material. For additional insulation, a layer of sound-absorbing material is laid between the drywall and the base ceiling. Soundproofing is glued to the base surface (through a special membrane) or laid on a frame, which is then lined with drywall boards. The inter-tile seam is pasted over with a sound-reinforcing tape. According to this principle, they make soundproofing of all other suspended ceilings: plastic, cassette, river, wooden. It should be noted that such a design weighs a lot and reduces the height of the room.

Stretch ceiling

In any stretch ceiling, the canvas can act as a soundproof membrane. But manufacturers also create more advanced canvases in terms of sound insulation. For example, the Clipso acoustic ceiling is a baguette with a complex section in which a microperforated canvas is fixed. Acoustic Cerutti ceiling consists of a multi-layer canvas, one of the layers is made of a foamed polymer that absorbs sounds.

An additional insulating lightweight material made of cork, coconut fiber, polyurethane foam can be attached to the base surface.

Acustic systems

These are ready-made acoustic ceilings, which are made of sound-absorbing materials. They do not require an additional layer of insulation. In addition, they are initially beautiful, they do not need to be painted or otherwise finished.

Acoustic suspension systems structurally represent a ceiling frame made of light metal, to which acoustic ceiling panels are attached. The Armstrong speaker system is the most popular.The panels in such a ceiling are made of mineral fiber, their front side is finished with a decorative coating, so the Armstrong ceiling does not need additional finishing.

Professionals are well aware of the Ecofon ceiling system, it is made of porous glass wool. Acoustic ceiling Roquefon is made of basalt mineral wool. Basalt mineral wool, in addition to high noise-absorbing properties, has moisture resistance and can be used as a heater.

If already at the construction stage the developer does not pay attention to acoustic insulation, if the residents themselves, not caring at all about the comfort of their neighbors, arrange an “anti-neighborly” floor, you can constantly conflict, or you can solve the problem once and for all - install acoustic ceilings in the apartment. They perfectly cope with their task - they provide good sound insulation, and at once in both directions. With acoustic ceilings, you and your neighbors are guaranteed not to disturb each other.

Add your comment

Suspended ceilings

Perforated acoustic ceiling panels are suitable for forming suspension systems in any room. Plates with a side of 595 mm, a thickness of 8.5 mm with perforation up to 9–15% of the sheet area absorb sound waves.

They have a number of advantages:

- Simplicity and convenience of installation. Small in size and light in weight elements are stacked on the frame. Work within the power of a home master without the help of specialists.

- Fire safety. During the manufacturing process, the finish is impregnated with special compounds - flame retardants.

- Resistance to temperature changes. Ceiling plates tolerate plus and minus temperatures. As for resistance to mechanical stress, the ceilings are not subjected to significant loads, so this nuance is not considered.

Ease of maintenance and plenty of design options complete the list of pluses. Manufacturers offer plate products made with a pattern, from different materials, with the possibility of forming curly structures.

Ceilings Armstrong acoustic

The long and well-known acoustic suspended ceiling from an American company remains the most popular among owners of office and retail premises. Structurally, the system is a frame on which plates are laid out in the form of a square with a side of 595 mm or rectangles with a format of 1190x595 mm. Fixing with spring latches, exposing the plane strictly horizontally.

Acoustic false ceilings Armstrong have many advantages:

- aesthetic appearance;

- simple installation;

- affordable cost;

- readiness of elements - all parts have a front coating, do not need additional decoration.

The material of manufacture is mineral (basalt or glass) fiber or a universal mixture of cellulose and mineral fibers.

Also, the advantages of Armstrong ceilings include light weight. The frame system allows you to hide communications, avoid work on leveling the base plane. There are no flaws in the finish, plates damaged during operation are renewed in a matter of minutes - remove the defective element, put new one in its place. For luminaires, special plates with a grate or solid panels with a grating strip are produced, into the holes of which it is convenient to embed lighting fixtures.

Acoustic ceilings Ecophon

The products of the Swedish company are distinguished by a high level of quality and a variety of forms.

Structurally, the products resemble Armstrong ceilings, since they also consist of a frame and slab elements, but there are differences:

- The profile system for finishing Ecophon has a T-shape. There are closed, open and semi-closed systems.

- The plates are made of multi-layer, they do not burn and resist moisture. In the manufacturing process, they are pressed under the influence of high temperatures.The basis of raw materials is compacted fiberglass, supplemented with synthetic components. The front side of the plate is covered with a special textile with a mesh laid on top of it - such a multi-layered structure strengthens the parts, making them resistant to mechanical stress.

- Plates can be decorated with paints in any shade.

- The size of the elements is 600x600 mm or 600x1200 mm, thickness 15-40 mm.