Repair in Khrushchev

For those who are engaged in the repair and decoration of their own home, quite often the question arises: what is the thickness of the ceiling in the room? Sometimes it is really very important to know, because the characteristics of the materials and the type of tools that can be used in the repair process sometimes depend on this.

If you are renovating a room in Khrushchev, you should be well aware of all the features of the layout of such a room. As a rule, in such buildings, the ceilings consist of special slabs. They can adjoin each other not closely, but with rather noticeable gaps. Sometimes this becomes problematic when decorating rooms in Khrushchev, so you should definitely take this feature into account when choosing a material for ceiling covering. Another unpleasant moment is associated with protruding beams, which can be of different sizes, in addition, quite often they are covered with cracks and chips.

As a rule, all surfaces in Khrushchev have a rather low level of sound and noise insulation. This should also be kept in mind when renovating an apartment in this kind of building. You will have to choose special protective materials that will make the room more comfortable for living. The thickness of the ceilings in Khrushchev can range from one and a half to two and a half meters (this depends on the series of the house).

Such architectural features largely determine the choice of material and the method of finishing in such premises.

Features of repair in a panel house

The panel house has slightly different layout features and its typical thickness of ceilings. First of all, it should be noted that in such buildings it is very difficult and problematic to carry out any redevelopment of the premises. Even the smallest changes can cause significant damage to the entire house.

But, of course, minor repairs are in most cases necessary, and they can be carried out, but very carefully and carefully, taking into account all the features of such buildings, in particular, the thickness of the ceiling.

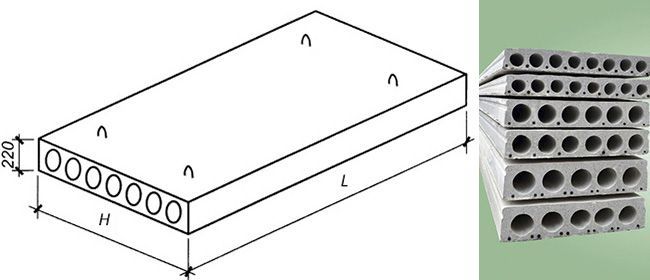

As a rule, all coatings in a panel house, in contrast to the option described above, do not have joints and seams. They are created from a single piece of fabric without any irregularities. Moreover, such slabs in their structure can be hollow or "filled". In the first case, the thickness of the plates is about 220 mm, and in the second - 120 mm. According to experts, thanks to such characteristic features of the structure of panel houses, it is much easier to finish such premises than to repair apartments in some other buildings.

Regardless of which house your apartment is located in, when repairing and decorating the premises, you must represent all the features of the ceiling very accurately and reliably. Knowing all the necessary indicators, you will be able to independently calculate the permissible load level and realize what types of lighting fixtures can be used, how best to organize sound insulation and carry out other types of repair work. This will allow you to avoid various undesirable consequences and make your home comfortable and absolutely safe.

How to insulate floors

- The best solution would be to purchase ready-made mineral wool slabs.

- Make the bottom layer from a sheet of roofing material, filling it with clay (mixed in half with sand), slag and sawdust from above.

- Special wood boards made from sawdust and concrete. You can buy them ready-made or you can make your own. To do this, 0.3 parts of cement mortar, 4 parts of clay, 1.5 lime and 2 parts of water are used for one part of sawdust. The plates are formed to a given size, dried a little and used as thermal insulation.

The video shows how to insulate the interfloor ceiling in a private house:

Floor slabs of the modern assortment open up wide possibilities for individual construction. Thanks to many options, it is possible to implement the most unexpected architectural projects and ideas. When erecting buildings, it is possible to combine and modify existing types of load-bearing structures, the main thing, first of all, to be guided by the basic safety rules.

Comparison table.

partition type

Floor load from 1 m / n partition, kg

Estimated cost of 1 m / n partition, $

Strength

Deformation susceptibility

heat and sound insulation

fire resistance

Brick partitions in half a brick

580-620

Brick partitions in a quarter of a brick

cracks are possible if there is a heavy door in the partition

Partitions made of tongue-and-groove and simple gypsum slabs 8-12 cm thick

cracks are possible if there is a heavy door in the partition

Partitions made of foam concrete 9-12 cm thick

cracks are possible if there is a heavy door in the partition

Partitions with wooden frame

depends on the material of the skin and the frequency of the bars

depends on the thickness of the bars used and the frequency of their location, from low to high.

depends on the type of cladding, from very low to low

Partitions with metal frame

depends on the skin material and profile frequency

depends on the width of the profiles used and the frequency of their arrangement, from low to high

low to high

Glass block partitions

140-150

cracks are possible if there is a heavy door in the partition

Transformable partitions

20-150

low to very low

extraneous loads are not desirable

very low to medium

Notes:

- The weight of 1 m / p is indicated for a standard partition height of 2.5 m. For higher partitions, the weight will be more, for lower partitions - less.

- The floor loading does not include plaster or sheathing with drywall, plywood, chipboard or wall panels. 1 m / p of a plaster layer 1 cm thick will add about 37 kg to the indicated load.

- Floor slabs in residential buildings are designed for a load of up to 400 kg / m 2 without taking into account structural loads. The total load-bearing capacity of the floor depends on the structure of the house and averages around 600 kg/m 2 , but the existing screed or future furniture must not be forgotten.

I hope, dear reader, the information presented in this article has helped you at least a little to understand the problem you have. I also hope that you will help me get out of the difficult situation in which I recently found myself. Even 10 rubles of help will be of great help to me now. I don’t want to bore you with the details of my problems, especially since they are enough for a whole novel (in any case, it seems to me so, and I even started writing it under the working title “Tee”, there is a link on the main page), but if I was not mistaken in your conclusions, then the novel will be and you may well become one of its sponsors, and possibly heroes.

For terminals Yandex Wallet number 410012390761783

For Ukraine - hryvnia card number (Privatbank) 5168 7422 0121 5641

webmoney wallet: R158114101090

Categories:

- Design elements. Walls . Partitions

- Diagnosis and treatment

User rating:

Not

Comments:

Note: Perhaps your question, especially if it concerns the calculation of structures, will not appear in the general list or remain unanswered, even if you ask it 20 times in a row. Why, is explained in sufficient detail in the article “Make an appointment with a doctor” (link in the header of the site).

The thickness of the walls in panel houses is the main factor determining the load-bearing walls and partitions. In our time, the problem of redevelopment of apartments in such houses has not lost its relevance.

The demolition of internal fences in apartments of panel houses allows the owners of dwellings to change the layout of the living space in the direction of reducing the number of small "rooms" and getting a more spacious room.

Key features and specifications

A slab is a rectangular flat piece of metal, stone or other material and is an integral part of a building. In construction, this element bears the full weight of other parts of the structure.

The main characteristics for overlapping are:

- strength, due to the need to withstand large design loads;

- rigidity, since there should be no perceptible kinks in the overlap even under the influence of significant loads. The allowable value is 1/200 span for attic floors and 1/250 span for floors between floors;

- sound insulation should provide sufficient protection of the room from the transfer of sounds from other rooms located in the neighborhood;

- thermal protection;

- fire resistance;

- efficiency implies the smallest weight with a small thickness;

- the industrial character of all elements.

The total cost of structures is usually 15-20 percent of the total cost of the entire building. Therefore, a correct and rational approach to choosing a floor structure will help to significantly reduce the level of financial costs and at the same time maintain all the necessary aesthetic and operational qualities of the building.

With well-chosen and coordinated dimensions of the structural elements of the house, only standard parts can be used in construction.

What are floor slabs

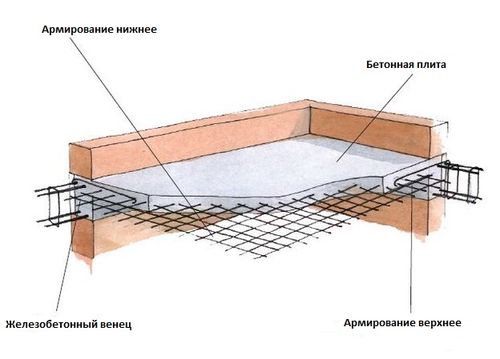

The main elements, consisting of heavy precast concrete slabs, are called floor parts. The upper part provides sound insulation and heat, while the lower part acts as a ceiling.

In the construction industry, such slabs are usually made of concrete or reinforced concrete. A distinctive feature of ribbed reinforced concrete structures is the presence of a gap between the ribs, which is about 150 cm. Reinforced concrete beams, quite tightly fitted to each other, can also act as floors. In such cases, in beam ceilings between beams, it is recommended to insert special inserts and concrete the gap formed between them.

In residential buildings or cottages with brick, block or concrete walls, reinforced concrete structures are most often used as floors. They are located both along the building and across, depending on the features of the project. The material for the slabs, in this case, can be light or ordinary heavy concrete grade 200 or more. Very often, in order to reduce the weight of the slabs, as well as save concrete, they are made with longitudinal round voids. The width of the plates can vary between 600-2400 mm, with a length of 2400-6600 mm. If necessary, for large spans without additional installation of supports, ceilings with a structure length of up to 12000 mm can be produced.

Beam ceilings

In this version, the structure is assembled from separate elements (metal, reinforced concrete, wood) located at an equal distance from each other, on a wall erected along the roof or the foundation of the building. In private, one-story housing construction, timber floors are popular. It is lighter and does not exert a strong load on the walls.But for them there are certain standards that limit their use in overall rooms. In the interfloor span, a wooden beam is allowed for laying if the width of the rooms does not exceed 5 meters, for attic floors no more than 6 m. A metal channel is used in almost all options.

Wooden beams are made of softwood or larch. On the upper side, a flooring is organized, which additionally performs the function of a floor. In addition to the main elements, the design of the beam ceiling includes rolls and insulation. So that over time the beams do not sag, and this can happen even if the standards are observed, it is recommended to lay them at a certain distance. The cross section is selected based on the bearing load exerted on it by the roof structure of the house.

How to properly repair load distribution

Dismantle (remove excess) and dispose of construction debris

This is important to prepare the front of the work.

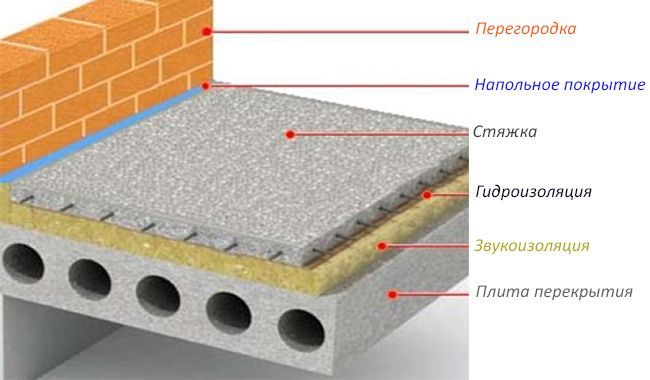

Think over and calculate the pie of the floors. If a large layer is required, then use lightweight materials (foam, expanded clay)

These materials do not give a large load on the floor slab and provide sound insulation.

Partitions collect from light materials. Do not use brick for building internal partitions - the weight of a brick partition (hollow brick) is 200-220 kg/sq.m. Accordingly, a small brick wall with an area of 10 square meters will weigh more than 2 tons.

- Never pour a layer of cement screed more than 4 cm. There should always be a “pie” of floors: thick layers of light materials below, and a cement screed and a thin layer of self-leveling self-leveling floor (0.4 - 0.9 cm) on top.

- Consider the weight of finishing materials. Natural stone can transfer loads from 60 kg/sq.m. If you have already completed the work and raised the level of the floors, then it is correct to replace heavy finishing materials with lighter ones, for example, porcelain stoneware.

- Make sure that during the repair, the storage of dry mixes is not organized at one point. Divide mixtures into groups and store them in different rooms.

- Always turn to professionals and do not save on specialists. Repair does not forgive mistakes. Repair requires knowledge and experience, never allow amateurs or those who do not understand the difference between M: 300 and M: 500 to work.

A source

Ceilings in a brick house

When installing beam vaults on stone and brick walls (red and silicate bricks, ceramic blocks, as well as lightweight concrete blocks with fine aggregate from slag, expanded clay, and so on), one should not forget about the hydroprotection of the ends of the beams. Reliable waterproofing of the end sections of wooden beams is performed in the ancient way - bituminization, impregnation with hot resin and obligatory wrapping with roofing material, roofing felt, hydroisol, euroroofing material - any of the rolled waterproofing materials. At the same time, the cut end is left clean, having performed only antiseptic and fire protection. Another general rule for the installation of floors on stone and block walls is to provide ventilation gaps in the support nodes of wooden beams. Condensing moisture must have a free exit, then the wood of the load-bearing beams will work much longer without destruction and loss of bearing capacity. In order for the ventilation of the ends of the beams to work, it is necessary to accurately fulfill the design dimensions of the openings in the walls in the areas where the wooden beams are supported.

Standard steps for installing a wooden beam in a brick house:

- Wall niches for beams are equipped even during the masonry process, especially for supporting floor beams. At the design mark, a niche with a depth of 150-200 mm is left, depending on the section of the beam and the features of its support. When block laying walls and laying with double bricks, an opening is left in a simple way - without laying one block. Reinforcement of the wall at the beam support area - with reinforcement mesh and / or embedded parts.

- A wooden beam-beam is treated with flame retardant and bioprotective compounds, and the ends are cut at an angle of 60-65 degrees to increase both the ventilation gap and the end beam surface to evaporate moisture from the wood.

- The beams are mounted in such a way that there is a gap of at least 50 mm from the straight end of the beam to the wall surface - for air circulation.

- Anchor fastenings of beams to walls are carried out on bolts, according to the calculation, but not less often than in every fourth support node.

- All gaps between the beam ends and the bearing walls are insulated with non-combustible heat-insulating material.

- The upper floor structure: on wooden beams, this is most often a bar lathing (beam 40 * 40; 50 * 50), and then fasteners for a panel wooden deck. Lightweight concrete coating on beams and other materials are also possible.

- The lower sheathing is in the simplest version plasterboard on a lath crate, or boarded for finishing by plastering (on a grid) or plastic cladding, GVL, chipboard, DSP, and so on.

All wooden floors have a complex cake, equipped with both hydro and vapor barrier. They also take measures to reduce the noise level - so that the impact noise created in the house and sounds from the street are not transmitted through the supporting structures of the house. Noise protection is carried out both technologically and with the use of special materials and fasteners with the option of noise damping.

Insulation of interfloor wooden floors is carried out in full above the basement and cold attic, and lightweight - between floors. But loose heaters (expanded clay gravel, perlite, vermiculite), as well as mineral insulators, protect not only from heat loss, but also improve the sound insulation of the house. Insulation options made of clay and straw, clay-sand, slag are successfully used today, according to environmental trends and in order to save money.

Backfill or slab (mats, blocks, ecowool, etc.) insulation is placed between the logs fixed on the flooring in the range of 0.5-0.7 m. The finishing flooring is made of planed boards along the logs. Another option is a light-weight concrete warm reinforced screed on a panel deck or panels, but this option is exclusively calculated. Even a light concrete mixture on vermiculite aggregate will give a considerable load on the ceiling and walls, incomparable with the weight of the log and boardwalk.

The last stage is finishing on the floor and ceiling.

Next - about the implementation of floors in the house of aerated concrete.

Documentary wall thickness setting

Still, such methods for determining the transverse dimension of the fence do not exclude the occurrence of errors. If the need for such measurements is caused by future demolition of walls inside the apartment of a panel house, then the dismantling of the fence must be carried out in a legal manner.

Independently redevelopment of living space is strictly prohibited by law. To avoid penalties, and in case of emergencies not to fall under criminal prosecution, you need to do the following:

- In the local executive body (BTI) you need to get a copy of the plan of the apartment.

- Based on the layout of the load-bearing fences and partitions, determine the fence to be demolished.

- In the design organization, order the development of technical documentation for the demolition of the wall.

- Based on the approved project, obtain permission for redevelopment from local authorities.

- After that, start work.

Materials and structural finds

The weight that a floor slab can withstand directly depends on the brand of cement from which it is made.

Floor slabs are made of concrete based on cement grade M300 or M400. Marking in construction is not just letters and numbers. This is coded information. For example, cement brand M400 is able to withstand a load of up to 400 kg per 1 cc per second.

But one should not confuse the concepts of "able to withstand" and "will always withstand."These same 400 kg / cc / sec is the load that the M400 cement product will withstand for some time, and not constantly.

Cement M300 is a mixture based on M400. Products from it endure smaller one-time loads, but they are more plastic and withstand deflections without breaking through.

Reinforcement gives concrete a high load-bearing capacity. Hollow core slab reinforced with grade AIII or AIV stainless steel

This steel has high anti-corrosion properties and resistance to temperature changes from -40˚ to + 50˚, which is very important for our country

In the production of modern reinforced concrete products, tension reinforcement is used. Part of the reinforcement is pre-tensioned in the mold, then a reinforcing mesh is installed, which transfers the stress from the tensioned elements to the entire body of the hollow core slab. After that, concrete is poured into the mold. As soon as it hardens and acquires the desired strength, the tension elements are cut off.

Such reinforcement allows reinforced concrete slabs to withstand heavy loads without sagging or bending. At the ends, which are based on load-bearing walls, double reinforcement is used. Thanks to this, the ends do not “break through” under their own weight and easily withstand the load from the upper load-bearing walls.

Types of hollow core floor panels

Panels with longitudinal cavities are used in the construction of ceilings in residential buildings, as well as industrial buildings.

Reinforced concrete panels differ in the following features:

- void sizes;

- the shape of the cavities;

- outer dimensions.

Depending on the size of the cross section of the voids, reinforced concrete products are classified as follows:

- products with cylindrical channels with a diameter of 15.9 cm. Panels are marked with the designation 1PK, 1 PKT, 1 PKK, 4PK, PB;

- products with circles of cavities with a diameter of 14 cm, made from heavy grades of concrete mix, are designated 2PK, 2PKT, 2PKK;

- hollow panels with channels with a diameter of 12.7 cm. They are marked with the designation 3PK, 3PKT and 3PKK;

- round-hollow panels with a cavity diameter reduced to 11.4 cm. They are used for low-rise construction and are designated 7PK.

Types of slabs and floor construction

Types of slabs and floor construction

Panels for interfloor bases differ in the shape of longitudinal holes, which can be made in the form of various shapes:

- circle;

- ellipse;

- octahedron.

Round-hollow products also differ in dimensions:

- length, which is 2.4–12 m;

- width in the range of 1 m3.6 m;

- thickness of 16–30 cm.

At the request of the consumer, the manufacturer can produce non-standard products that differ in size.

The main characteristics of hollow core floor panels

Cavity slabs are popular in the construction industry due to their performance characteristics.

Calculation for shearing of floor slabs

Calculation for shearing of floor slabs

Highlights:

- extended range of products. Dimensions can be selected for each object individually, depending on the distance between the walls;

- reduced weight of lightweight products (from 0.8 to 8.6 tons). The mass varies depending on the concrete density and dimensions;

- permissible load on the floor slab, equal to 3–12.5 kPa. This is the main operational parameter that determines the bearing capacity of products;

- brand of concrete mortar, which was used to fill the panels. For manufacturing, concrete compositions with markings from M200 to M400 are suitable;

- the standard interval between the longitudinal axes of the cavities, which is 13.9-23.3 cm. The distance is determined by the standard size and thickness of the product;

- brand and type of fittings used. Depending on the size of the product, steel bars are used in a stressed or unstressed state.

Approximate calculation of the ultimate load on a hollow core slab

In order to independently calculate what maximum load the floor slabs that you plan to use during construction can withstand, you need to take into account all the points. Let's say that you want to use 1PK63.12-8 panels for arranging floors (that is, the value of the calculated load that one product can withstand is 800 kg / m²: for further calculations, we will denote it with the letter Q₀). By calculating the sum of all dynamic, static and distributed loads (from the weight of the slab itself; from people and animals, furniture and household appliances; from screed, insulation, finishing flooring and partitions), which we denote by QΣ, you can determine what kind of load your particular slab can withstand

The main point to pay attention to: as a result of all calculations (of course, taking into account the increasing strength factor), it should turn out that QΣ ≤ Q₀

In order to determine the uniformly distributed load from the own weight of the slab, it is necessary to know its mass (M). You can use either the weight value indicated in the manufacturer's certificate (if it was provided at the place of sale), or the reference value from the GOST table, which is compiled for products made from heavy types of concrete with an average density of 2500 kg / m³. In our case, the reference weight of the slab is 2400 kg.

First, we calculate the area of the slab: S = L⨯H = 6.3⨯1.2 = 7.56 m². Then the load from its own weight (Q₁) will be: Q₁ \u003d M: S \u003d 2400: 7.56 \u003d 317.46 ≈ 318 kg / m².

In some construction guides, it is recommended to use the total average value of the payload for the ceiling of residential premises in calculations - Q₂ = 400 kg / m².

Then the total load that the floor slab must withstand will be:

QΣ = Q₁ + Q₂ = 318 + 400 = 718 kg/m² ˂ 800 kg/m², that is, the main point QΣ ≤ Q₀ is observed and the selected slab is suitable for arranging residential floors.

For accurate calculations, specific density values \u200b\u200b(screed, heat insulator, finish coating), the load value from partitions, the weight of furniture and household appliances, and so on, will be needed. Standard load indicators (Qn) and reliability factors (Yn) are specified in the relevant SNIPs.

Prefabricated-monolithic

Combination of slabs with formwork. This method simplifies the work of arranging floors in geometrically complex rooms. A good alternative to a monolithic design. Using this option, you must follow safety precautions. Where slabs are allowed to be laid, and complex architectural transitions are poured with concrete. Here lies the danger. It is necessary to work out the connection with the reinforcement of the slab and the monolith. With the natural draft of the house, the connection may crack and deform. Reinforcement will not allow this, and the overlap will comply with technological standards.

Of the advantages of this method, the ability to work on complex architectural objects stands out, and the disadvantages are only in the complexity of combining and the need to lay the formwork.

Any type of overlap can be used in brick housing construction. Restrictions affect only the beam method, which limits the freedom of action in relation to the overall premises.

Types of loads

Regardless of the type, any overlap consists of:

- 1. The upper part - flooring, floor insulation, concrete screeds, if a residential floor is located on top.

- 2. The lower part, which is created from sheathing materials, plaster, tile coverings, for example, ceiling trim and suspended structures, if there is a residential floor below.

- 3. Structural part, consisting of monolithic or prefabricated slabs.

The structural part is any type of floor slabs, while the upper and lower parts create a certain static (partitions, suspended ceilings, furniture) and dynamic loads (load from people moving along the floor, pets).In addition, there are also point loads and distributed loads. For residential buildings, in addition to static and dynamic, distributed loads are calculated, which are measured in kilogram-forces or Newtons per meter (kgf / m).

Loads during renovations of old apartments

Floor slabs can be made by hand. Reinforcement is made to make them stronger.

When planning luxury renovations in old houses, it is better to remove the old floor insulation and flooring in advance. Then you should at least approximately estimate its weight. It is advisable to choose new screeds, slabs or parquet that will replace them so that the weight of the new floor "clothing" is approximately equal to the mass of the former upper part of the floor.

You should be especially careful when placing new plumbing with increased volumes in old apartments - bathtubs of 500 liters or more, jacuzzis. It is best to invite a specialist and ask him to carry out detailed calculations. It should be remembered that short-term load and permanent static load are different from each other.

Static loads tend to accumulate, leading over time to significant deflections and sagging of the slab. A short-term load just tests it for strength.

In conclusion, I would like to say that only exact observance of all the rules and thoroughness in the calculations will ensure a long life for floor slabs.

Installation rules

To carry out reliable installation of hollow core slabs, it is necessary to strictly follow all the rules. If the support area is insufficient, the walls may deform, and in a situation with excess area, an increase in thermal conductivity is possible.

When installing plates of this type, it is worth taking into account the maximum support depth:

- for a brick structure - 9 centimeters;

- for aerated concrete and foam concrete - 15 centimeters;

- for steel structures - 7.5 centimeters.

In this process, it should be borne in mind that the depth of embedding the panel in the wall should not be more than 16 cm for a light block and brick building, as well as 12 cm for a concrete and reinforced concrete structure.

It is strongly not recommended to carry out the installation of plates without the use of mortar. A layer of mortar of at least 2 millimeters is laid on the working surface. Thanks to this event, the load on the wall is transferred evenly. When equipping the slabs on a fragile wall, it is necessary to make a reinforcement procedure, due to which there will be no bending of the blocks. In order to reduce the thermal conductivity of the floor slabs, it is worth insulating the structure from the outside.

When buying hollow core floor panels, you should pay attention to their quality, appearance and availability of certificates, since safety will depend on them. The use of hollow core slabs provides a small load on the entire perimeter of the structure, guarantees high strength and reliability of the structure

You can learn how to properly lay floor slabs in the video below.

How to measure wall thickness correctly

To find out the exact transverse dimension of the wall, you need to prepare the following tool:

- tape measure or ruler;

- chisel;

- screwdriver;

- perforator.

As a rule, measurement is made from the side of the doorway. To do this, perform the following actions:

From the side opposite to the door hinges, the platbands are carefully removed from both sides of the wall. If the platbands are glued, then they are carefully pry off with a chisel and removed.

At the junction of the fence to the rack of the frame of the doorway, a layer of wallpaper and plaster is removed.

A tape measure or ruler threaded through the gap between the concrete and the rack will show the exact thickness of the wall.