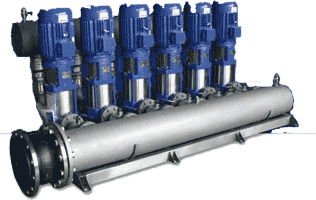

ZH Hydro-Vacuum pressure booster systems

Hydrophore installations are stations in which several pumping units are installed in parallel, which are designed to pump water, increase pressure in water supply networks, and compensate for hydraulic losses associated with the characteristics of the fed pipeline.

- Main applications:

- water supply networks, t water treatment plants,

- pumping stations in multi-storey residential buildings, individual houses and their groups,

- pumping stations in public buildings (hotels, schools, hospitals…),

- supply of fire hydrant systems,

- industrial water networks (cooling and process water systems),

- irrigation systems.

The pumping units are designed for pumping drinking or clean domestic water, the temperature of which does not exceed 70°C, without solid inclusions. Maximum operating pressure of the unit: 10 bar.

Design

Hydrophore installations are a system of several pumps, usually of the same size, connected in parallel with the supply and discharge manifolds using return and shut-off valves. The pumps are mounted on a supporting structure made of steel profiles. The supporting structure is equipped with vibration isolators, which makes it possible to mount the unit on the floor of the pumping station.

Pump units

The ZH type hydrophore units are equipped with pump units manufactured exclusively by Hydro-Vacuum S.A.

Basic structure

Welded construction made of steel profiles, which are seated on vibration isolators, which allows height adjustment by about 20 mm, as well as installation of equipment according to the level.

collectors

The manifolds connect the individual pumps of the plant on the suction-supply and delivery sides. They are a welded structure of pipes and normalized flanges. One-way manifolds are terminated with matching metal-rubber compensators and blanking flanges. The manifolds are equipped with connecting fittings that allow the installation of measuring and protective equipment (pressure transformers, pressure gauges, pressure regulators, LCA pressure switches). In each case, the collector system and their diameters can be adapted to individual requirements.

fittings

Each unit in the ZH plant is equipped with a shut-off valve with its own suction and discharge side, which allows, if necessary, to cut off this pump without interrupting the operation of the entire installation. A non-return valve is installed on the discharge side of each pump.

Design solution of the installation

Due to the need to fulfill various functional requirements and installation conditions, hydrophore units are offered in a wide range of design combinations, which are indicated by a four-digit code.

The horizontal frames of the units are designed so that any installation of the control cabinet is possible. The vertical frame of the control cabinet has an individual auxiliary frame, which, on the one hand, rests on the non-bearing structure of the pumps, and on the other, on additional vibration isolators.

Aspect 2 - unit volume and pressure

The main factor to consider when choosing the volume of a hydroaccumulator is the average amount of water consumed by a family. Productivity is calculated based on the amount of water spent in 1 hour. There are average values, but they are usually taken as a minimum. For example, a family of 4 living in a small private house needs a hydrophore with a capacity of 2-3m³/h. A large family living in a two-story cottage with a garden plot should count on a productivity of at least 7-8 m³ / h.

In addition to a dry count of the number of residents, their lifestyle should be taken into account: some wash once a week, others daily. A number of household machines and appliances also run on water - washing machines and dishwashers, hydromassage and shower systems, or gardens.

Advantages and disadvantages of pumping stations with a hydraulic accumulator

If we talk about the advantages that a pump with a hydraulic accumulator has, then the most significant of them usually include the following.

- In water pipes served by pumping stations with a hydraulic accumulator, which is always full, a constant supply of water is ensured.

- A hydraulic accumulator for a pumping station, the main structural element of which is a membrane that creates the required pressure of the liquid medium in the system, ensures the supply of water to the pipeline even when the pump is not operating. However, water will flow into the pipeline when the pump is not working only until it runs out in the tank of the hydraulic tank.

- The use of a hydraulic accumulator eliminates such a negative phenomenon as water hammer in the pipeline system.

- Water pumps operated in conjunction with a hydraulic tank have a longer service life, as they operate in a more gentle mode, turning on only at those moments when the fluid level in the accumulator drops to a critical level.

For any water supply system, you can choose the right accumulator

Among the disadvantages of pumping stations with a hydraulic tank, the following can be distinguished.

- It is necessary to allocate a decent area for the installation of such equipment, which is explained by the large dimensions of the accumulator.

- If the pressure switch fails, the site on which such equipment is installed will be flooded with water.

- The features of the hydraulic tank device imply the need for regular (once every 2-3 months) bleeding of air from its tank, which ensures the efficiency of such equipment (the hydraulic accumulator device requires a special valve for this procedure).

Pumping station for water supply

In addition to simply counting the number of people living, it is necessary to take into account their usual lifestyle, because many wash every day, and some only a few times a week. Most household appliances and machines also need water. They are dishwashers and washing machines, showers and automation systems for watering a personal plot.

It is also necessary to take into account the maximum pressure that the pump is capable of creating. Usually, the factory hydrophore is supplied with detailed instructions that can answer many questions. A special table lists the most important values that you need to rely on when installing a hydrophore.

The maximum pressure in the hydrophore must correspond to all devices that are included in the drinking water supply system. Among them it is customary to include devices that are installed in almost all country houses - different types of water heaters, boilers and boilers. The working pressure should be set when connecting the devices manually, using special adjustment bolts, but clearly adhering to the operating instructions.

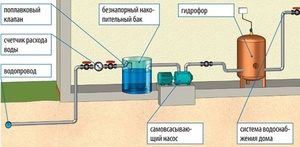

Pump device

Nowadays, several types of hydrophores for a country house are very popular:

- membrane, which are equipped with a flexible and sealed membrane that separates the storage tanks from water and air;

- membraneless, in which compressed air and drinking water are not separated, but are located in one compartment.

The elastic membrane is a special rubber bag that does not come into contact with the walls of the compartment in which it is located. Pumping stations with a membrane device are quite compact, have small dimensions and do not require a huge area for installation.They can be considered the best option for private houses with a small area. The maximum volume of the tank is up to 60 liters, however, models up to 110 liters are available for sale.

The suction motor is fixed at the top and connected to the tank with a flexible pipe. To regulate the air pressure, you must use a special nipple. Due to the design features, the membrane hydrophore practically does not make noise. In many models, it is possible to quickly replace a worn membrane mechanism. When purchasing a replacement membrane, it is necessary to check all its quality certificates, because the rubber will come into contact with drinking water.

The membraneless tank is a vertically placed cylinder with a volume of more than 110 liters. For a good water supply, along with a membraneless pumping station, it is worth buying a self-priming vortex pump. The maximum pressure should not exceed 0.7 MPa, because this indicator is considered the maximum for most hydrophores. Sometimes it is allowed to use pumps that provide high pressure, but for this you need to install a safety valve. The valve drain must necessarily lead to the sewer system. Stabilization of the total pressure in the drinking water supply system, good pressure at any point of water intake and protection from huge loads depend on the quality of the equipment of the pumping station.

What determines the operation of the pumping station

It must be remembered that the good operation of the pumping station is based on such factors:

- on the total volume of water used;

- on changes in general pressure indicators.

When the pressure drops to the minimum value in automatic mode, the pump starts and starts pumping water until the total volume of compressed air decreases and the pressure increases. A special pressure switch quickly responds to these indicators and turns off the pump. The value of the maximum pressure in the tank is set at the factory, but the operation of the relay must be adjusted by hand.

Equipment installation

Connecting at home

The small dimensions of such equipment allow you to install it in almost any corner of the room. This maybe a bathroom, terrace, utility room or kitchen. The maximum noise level can be different, but at high values it is necessary to make high-quality sound insulation. When installing a hydrophore, it is worth adhering to the basic requirements and standards that apply when installing electrical equipment and water supply systems in private homes.

Requirements for the premises for the installation of equipment:

- the total area of the room must be at least 4 square meters;

- the height of the room must be at least 2.3 meters;

- the distance from the wall to the pumping station must be at least 65 centimeters;

- the distance from the wall surface to the pump should be about 55 centimeters.

These rules must be observed not only when installing the hydrophore, but also other additional systems. Electrical equipment must have a high degree of protection against moisture. The temperature in the room should be positive, and the ideal option is its value from 4 to 26 degrees Celsius.

It is necessary to take care of a ventilation system that will ensure reliable cooling of the electric motor.When insuring against an emergency, it is worth making a slight slope of the floor and special sewer holes that will be able to divert water from operating equipment. The doors must also match the purchased pumping station so that it can be easily taken out or brought into the room.

The location of the pump in the well

The ceiling will be an ordinary reinforced concrete slab, and the door will be a special hatch, which is hermetically sealed with a lock. Moisture and fungus are able to penetrate into its cracks, so the hatch is closed with sheets of roofing material or a plastic lid. There are interesting options on the market from designers that mask various types of hatches. They are made in the form of plants, mushrooms or stones.

You can go down into such a well by a ladder, which is fixed on its wall. It is necessary to comply with all conditions for the placement of pumping equipment. The main ones are:

- safe lighting;

- reliable ventilation;

- sewer drain;

- good insulation.

It must be remembered that the hydrophore electric motor is poorly protected from fungus and moisture, therefore it is quite dangerous for humans. All of the above conditions must be taken into account when choosing and buying a pumping station.