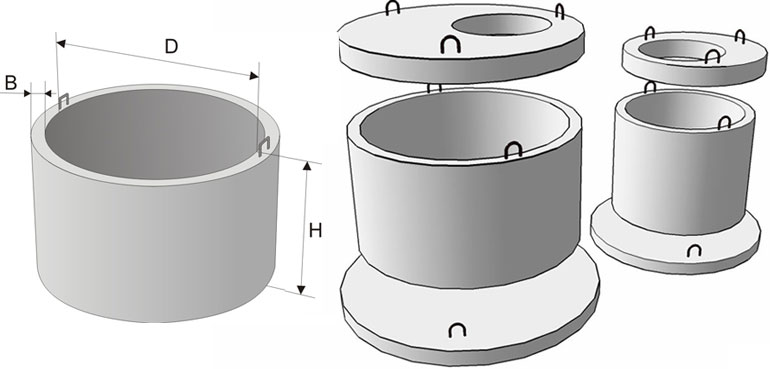

Product classification

Based on the technical characteristics, reinforced concrete rings for sewerage are:

- wall (ordinary);

- additional;

- castle;

- support;

- rings with a lid or bottom.

Ordinary wall rings are produced without auxiliary fasteners. They are joined on top of each other, and the protection against water permeability of the joints is carried out by means of cement mortar. Having chosen these concrete products for the well, you need to know that the overlap strength indicator will not be high. Therefore, they are not recommended to be installed in seismically active zones.

Additional reinforced concrete elements, unlike wall products, have non-standard sizes and are designed for atypical structures. To obtain the desired value, you simply need to dock ordinary products with additional elements. Castle reinforced concrete rings have 4 protrusions on top and 4 grooves on the bottom. This provides a tight and stable joint during assembly and eliminates shaft displacement in the horizontal plane.

When filling the groove in the upper part with cement mortar and laying the rubber seal on top, the tightness of the structure increases. The support rings are needed for the further construction of the hatch and are mounted directly in front of the floor slab. And reinforced concrete products with a bottom or a lid are similar to wall elements, but they have, respectively:

- bottom;

- lid.

Dimensions of concrete rings for sewerage with which products are produced:

- diameter - 700, 1000, 1500, 2000 mm;

- height - 600, 900 and 1500 mm;

- the volume of the product depends on the combination of standard sizes.

Manufacturers also produce reinforced concrete products with custom dimensions.

Video: Septic tank made of concrete rings

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Technical characteristics of reinforced concrete rings for sewerage

For private construction, it is recommended to use reinforced concrete rings sewer grades KS, the dimensions for which can be 70 cm, 100 cm, 150 cm and 200 cm in diameter.

The next indicator of the concrete ring size is their height, which is not related to the diameter and can be 60 cm or 90 cm.

But the cost of such reinforced concrete products with a diameter is just interconnected, i.e., a smaller diameter - a lower price, etc. By the way, the numbers in the marking show the diameter, for example, KS-20-9 has a diameter of 2 m and height 90 cm or 900 mm

The table will show you the dependence of the cost on the technical data

|

Type of reinforced concrete rings |

Volume of reinforced concrete ring (m3) |

Approximate cost (rub) |

|---|---|---|

|

COP 10 - 9 |

0.71 |

1800 — 2100 |

|

COP 15 - 9 |

1.59 |

2750 — 3200 |

|

COP 20 - 9 |

2.83 |

4700 — 5350 |

As you can see, the larger the diameter, the more expensive the price. If you take COP 10 - 6, for example, then the cost will be much cheaper, namely, 1000 - 1300 rubles.

How to calculate the volume of the sewer ring and on what quantities does it depend?

Based on the main indicators of dimensions, we can determine that their values \u200b\u200band make up the formula for calculating the volume of a reinforced concrete ring.

You need to find out the total volume of the pit itself, for this:

The exact number of inhabitants of the house * daily water rate (l / person) * 3 (time for processing wastewater in days) \u003d volume of the well.

Example: 5 * 200 (set rate) * 3 days (constant) = 3 m3.

We calculate the internal volume according to the formula:

V=R2*h*P,

where V is the volume,

R2 is the radius of the ring,

h - height,

P = 3.14 (pi).

Typically, a drain pit is made about three meters deep. From this value we subtract 0.7 m and get the height of the ring.

In order to find out the radius, we remember the math and do the reverse calculation, i.e.: R2=V/P/h.

In our case, this will be displayed as follows: R2 \u003d 3 m3: 3.14: 2.3 m \u003d 0.65 m.

From here we see that a reinforced concrete ring must be bought with a diameter of 130 cm, and it was shown above that there are no such indicators - which means, by elimination, we choose a product with an indicator of = 150 cm.

Installation of reinforced concrete rings

Installation of sewer rings begins with digging a hole for a well, which can be done with special equipment or on your own with a shovel. Then it is better to call a few people to save time.

Knowing the volume and other indicators, we dig a pit, but in height and diameter we make it 0.5 m larger.

We ram the bottom of the well and fill it with a sand cushion of 8-10 cm, on which we put a reinforced concrete slab or fill it with concrete mortar.

We carefully lower the first reinforced concrete element onto the dried concrete and cement its contact with the bottom.

We bring the drain pipe to the hole prepared in advance.

We lower all the required rings in turn, each time concreting the points of contact.

It is advisable to carry out internal waterproofing too, and then cover it with a slab and build a hatch in it.

To fasten some reinforced concrete sewer rings, metal staples are used.

Nuances

There is a difference in reinforced concrete according to the type of manufacture:

- Monolithic - used for the construction of large objects by pouring the reinforcing cage with concrete along a given perimeter.

- Prefabricated parts - the types and number of products are distinguished by a wide range and are produced at the enterprise.

- Prefabricated-monolithic - made for each project separately.

For us, the most popular is the second option.

If you plan to lower products without the help of special equipment, then use boards that can, moreover, be used instead of guide parts.

For better immersion of the rings into the ground, there is one secret and it consists in an additional element welded to the outer edge. The element is a metal strip about 5 cm wide.

Conclusion

The main criterion when choosing building materials for arranging a sewer pit comes down to reliability and long-term operation, and these are the main indicators of reinforced concrete rings of any shape and different sizes.

Making reinforced concrete rings: video

Tell your friends! Tell your friends about this article on your favorite social network using the buttons in the panel on the left. Thanks!

This is interesting: What pipes to use for ventilation in a private house: we analyze the essence

How high quality products are achieved

The production of concrete rings for sewerage is carried out according to a special technique from high-quality material. The optimal brands of cement for mortar are M400 or M500, which ensures the durability of structures. Crushed stone of small fractions, sand and water are also used. The design is reinforced with a metal mesh along the side surface of the product. Due to the use of fittings, sewer rings are highly resistant to mechanical stress.

They are able to withstand various climatic influences and are distinguished by their aesthetic appearance. These reinforced concrete products (concrete products) are used for:

- arrangement of wells with drinking water;

- construction of septic tanks and wells for wastewater and sewerage;

- arrangement of cesspools;

- construction of various underground communications.

The main purpose and advantages of reinforced concrete sewer rings

The main material for the sewage disposal device are reinforced concrete sewer rings. Today you can find two types of such products - with locks and without them.Locks or folds in concrete sewer rings perform a connecting function. The connection of rings without folds is carried out by means of concrete mortar and metal brackets.

Euro standard rings with locks have the following advantages:

- the well shaft will always be flat;

- products do not need to be interconnected with brackets;

- they are produced with a larger diameter than traditional reinforced concrete (RC) elements.

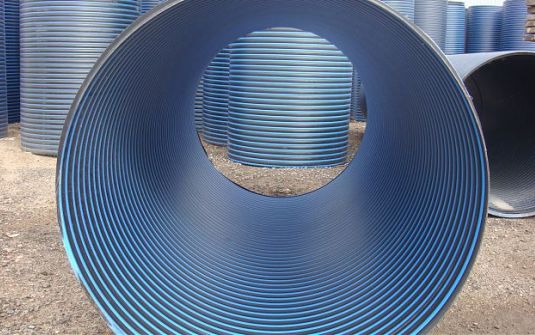

Plastic rings for a well

PVC leads today in terms of its implementation, the material is widely used due to its exceptional properties. Thanks to the rapid development of new technologies, plastic rings for the well appeared on the market in an assortment that, at first glance, is inferior in its diversity to concrete products.

However, manufacturers have the technical ability to produce PVC rings and containers of any configuration and size, by contacting the supplier, the interested consumer can order the required equipment.

Plastic rings for the well are made from:

- polyethylene, characterized by exceptional tightness and the ability to completely restore the original configuration after defrosting water;

- polypropylene, which has a high degree of plasticity, wear resistance and susceptibility to welding.

They comply with the requirements of SN, SNiP, SanPIN and other regulatory documents, and are approved for use in drinking water supply systems.

Models with increased rigidity with a diameter of 800 and 900 mm and a height of 1500 mm are in the greatest consumer demand. The wall thickness of such rings is usually made with a size of 25 mm.

The cost of 1 plastic section ranges from 8,000 to 14,000 rubles.

Compared to concrete, PVC rings have many advantages, including:

- exceptional wear resistance;

- complete tightness;

- hygiene;

- light weight: one section weighs no more than 40 kg;

- resistance to most adverse external factors;

- convenience and ease of transportation, storage and installation.

Produced sizes and prices of rings for a well, manufacturing companies publish in their catalogs. When making models to order, depending on the requirements of the customer, reducing or increasing coefficients are applied to standard prices.

Advantages and disadvantages of reinforced concrete rings

It is no secret that any building material has its strengths and weaknesses. This feature also applies to finished products. Concrete rings seem ideal, but even they are not without some drawbacks.

The undeniable advantages of ZhB-rings include the following:

-

High quality at an affordable price.

-

Wide size range.

-

The ability to quickly equip the water supply and sewerage system.

-

High tightness: a tight fit of the seams prevents groundwater from entering the structure.

-

Long service life: reinforced concrete is neutral to any environment, so it can last at least 100 years.

-

Rigidity of the structure: wells made of concrete rings can be mounted even on unstable ground.

Obvious disadvantages include the following:

-

Dimensions and weight: it is impossible to install a concrete ring without the use of construction equipment, which somewhat "weights" the cost of installation.

-

Lack of mobility: it is very difficult to move such a well.

It can be seen that there are more positive features, this explains the steadily growing popularity of concrete rings.

The main stages of installation of a sewer well

The device of a sewer well made of concrete rings is technologically simple, difficulties arise only because of the large weight of the products. They can be installed in the country with your own hands, without involving equipment. They use the old method of digging under the rings. Only wall rings are besieged, and if a bottom is required, they are poured on their own.

Choosing a place for a septic tank

For containers, a small area is needed, remote from other objects. According to sanitary and building codes, distances must not be less than the following values:

- from home - 5 m;

- to common roads - 5 m, access roads - 3 m;

- from the well - 30 m;

- from the border of the neighboring site - 3 m;

- to the reservoir - 20 m.

When designing the location, take into account that the entrance of equipment is required. They try to choose more distance to the playground, summer kitchen, swimming pool. From anaerobic septic tanks, even with the most perfect ventilation, the smell still comes out.

Installation

The order is this:

- dig a pit of the required depth, the diameter is larger than the rings;

- a concrete slab is laid at the bottom of the pit or a foundation is poured;

- lower the rings with simultaneous waterproofing of the joints;

- overlap is installed on top;

- install drain pipe.

From the septic tank, drains should not seep into the ground. For additional sealing of joints, cement with additives that increase strength is used.

For a drainage well, this is not so important: its purpose is to divert effluents into the soil, they are no longer so dirty. The bottom ring can be installed with holes in the finished product

Lockless well rings are still seated on the solution so that the structure does not move under the pressure of the soil.

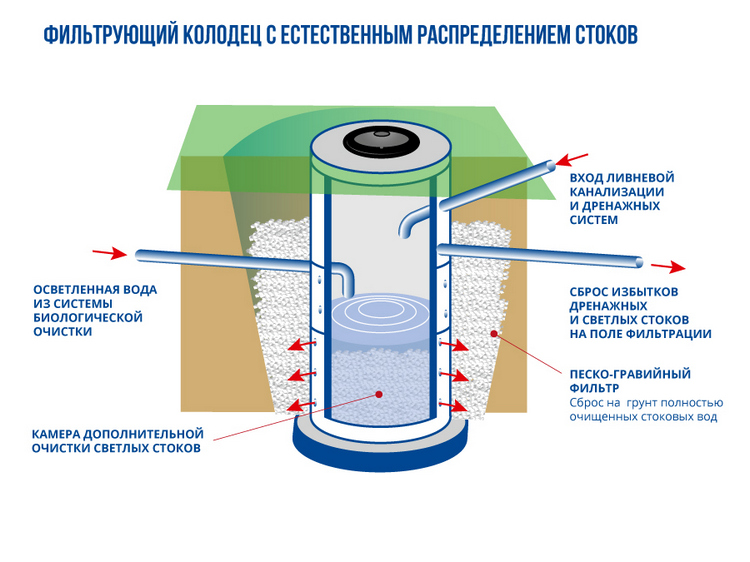

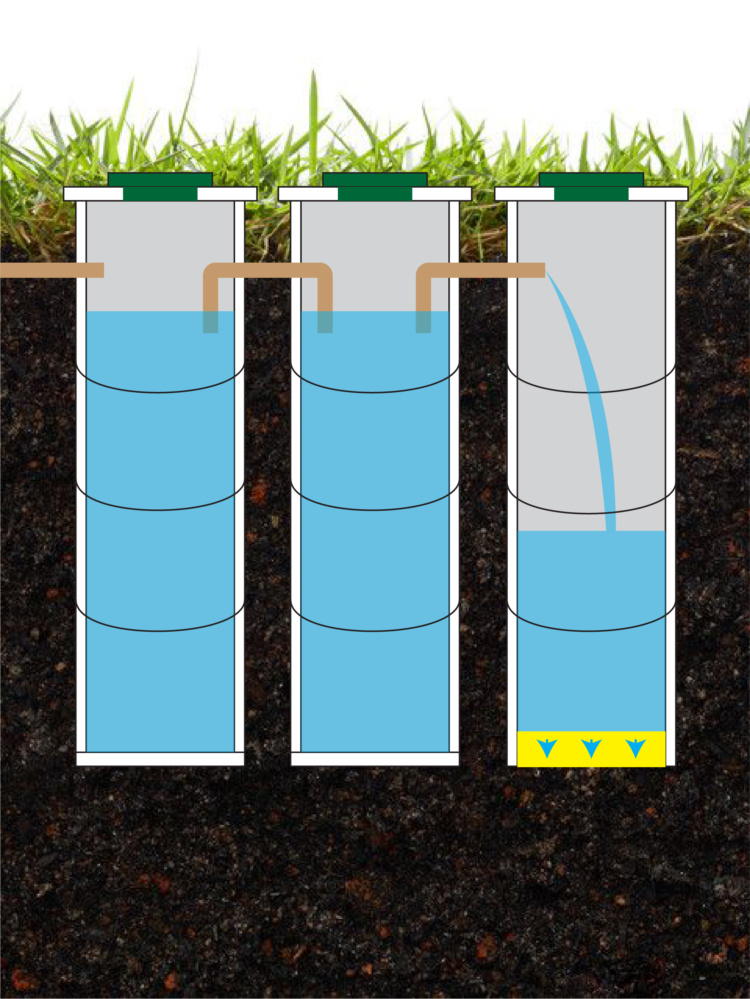

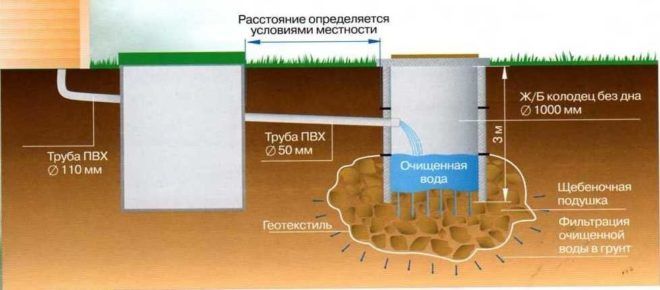

The filtration well is built in the following sequence:

- pour sand 0.5 m high from the bottom of the pit;

- top - 20 cm gravel;

- install rings, overlap;

- if the lower ring is perforated, the space between it and the ground is covered with rubble;

- connect the wells with an overflow pipe.

Over the ceilings, necks with lids are installed. The hatch is necessary for periodic inspection of septic tanks. The structures are covered to the top with earth so that a neck with a lid rises 10-15 cm above the surface.

Filter well design

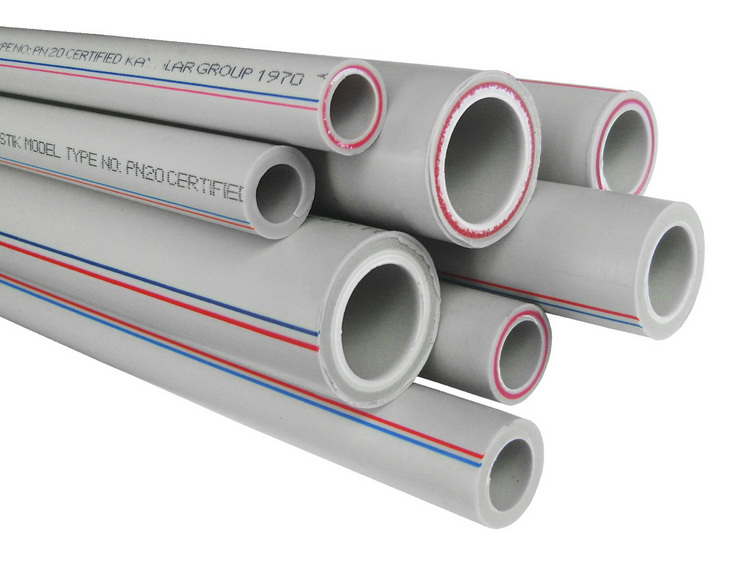

Types of sewer pipes

Sewer pipelines are made of metal, polymers, ceramics, concrete and asbestos.

Steel pipes are durable, operated at any temperature. Advantages crosses out susceptibility to corrosion. In a private house, they are now rarely used.

Cast iron is more expensive than steel pipes, heavier, but corrodes less. Sometimes they now make risers, external conclusions. They are heavy and difficult to seal. Dirt is deposited on the rough inner walls, and the permeability decreases.

Polymer sewer pipes have smooth walls, which ensures maximum throughput. They are divided into several groups depending on the material:

Different shapes of PVC pipes

- polyvinyl chloride (PVC);

- from unplasticized polyvinyl chloride (UPVC);

- polypropylene (PP);

- polyethylene (PE).

PVC products are used for internal and external non-pressure sewage. They are not affected by ultraviolet, they have sufficient strength. In everyday life, SN2 is used if the system is laid at a shallow depth and does not cross roads. SN4 is used if necessary to lay pipe under the road with a small load, for example, under the entrance to the garage. PVC is not resistant to temperature extremes, aggressive substances, they burn, releasing toxic gas.

Polypropylene is recommended to be used only for internal sewage, as it is soft and easily deformed under load. It withstands high temperatures and has a long service life. PP products are environmentally friendly, resistant to aggressive substances.

Sewer polypropylene pipes of various diameters

Polyethylene pipes are not recommended for use in sewers with hot drains above + 40 ° C - expansion and elongation occur. Withstand frosts down to -40°C. Low pressure polyethylene has higher qualities:

- maintains temperature to -70 °C;

- resistant to water hammer;

- does not change size with increasing temperature.

Disadvantages are present: HDPE has low strength, external sewage is located only underground.Afraid of ultraviolet radiation, does not withstand high temperatures.

Ceramics are used in industrial systems: they are fragile and difficult to install. In everyday life, asbestos and concrete pipes are sometimes used for the construction of short lines.

What are the rings. Types and purpose

Well rings are round reinforced concrete structures used for arranging engineering communications buried below ground level. Depending on the structure being constructed, the following types of rings are used:

-

Sewerage and water intake.

-

Products for laying underground cable networks.

-

Collectors.

-

Gas pipelines and water intakes.

In addition, there are such varieties on the market:

-

Rings with a flat and lock end.

-

Repair.

-

Additional.

-

Support.

Regardless of the type and purpose, the products are made of heavy concrete, grade 200-500, reinforcement is performed.

This is interesting: Which fence posts are better to use - we tell the main thing

What are concrete rings for?

Most often, concrete rings are needed for the construction of a well, but they are also used in the construction of an autonomous sewage system - they make septic tanks or filtration wells. Another area of application is manholes in the construction of a storm and drainage system. Even cellars are made of concrete rings. And there are different options - vertical, horizontal. In general, the scope is wide.

Concrete rings are used for the construction of various structures

There are rings of different sizes for different needs, they also have different wall thicknesses, they can be with or without reinforcement. Despite such an abundance of choice, many are thinking about making reinforced concrete rings with their own hands. The thing is that when arranging a site, you may need more than one ring, and not even ten. For some, it takes more than a dozen just to make a well. The cost of manufacturing reinforced concrete products is much lower than their retail price. Even taking into account the fact that you have to make molds for concrete rings. And if you also take into account the cost of delivery, then the savings are very solid.

How to make concrete rings with your own hands

This question is relevant for those who need at least a dozen rings. If 4-5 rings are enough for a septic tank or a well, then it is better to buy finished products and do not engage in manual production. The formwork for such a structure is quite difficult to manufacture, and casting requires great care. Otherwise, the rings may turn out to be uneven and fragile, with voids in the concrete.

The ratio of components for the preparation of concrete can be taken as follows: 1 part of cement, 1 part of crushed stone, 3 parts of sand. Add water to the mortar mixer carefully, in small portions. The working consistency of the concrete mixture must be such that it is evenly distributed inside the form.

Here are the main technological requirements, without which the manufacture of concrete rings with your own hands will not give the expected quality:

- Strong steel collapsible form;

- High-quality cement (grade not lower than 500);

- Fine aggregate (crushed stone fraction 5-10 mm "seed" and washed sand);

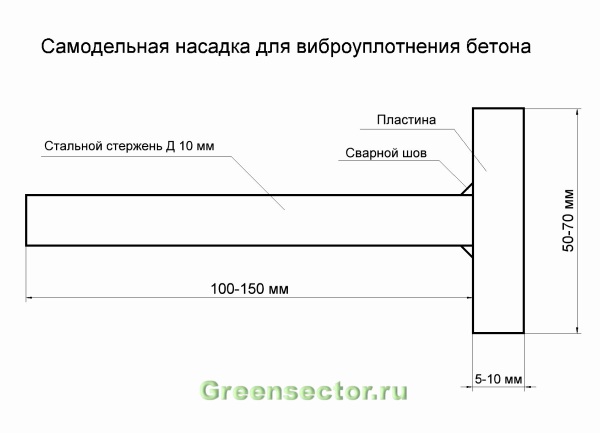

- Vibrocompaction of the concrete mixture;

- In the cold season, electric heating.

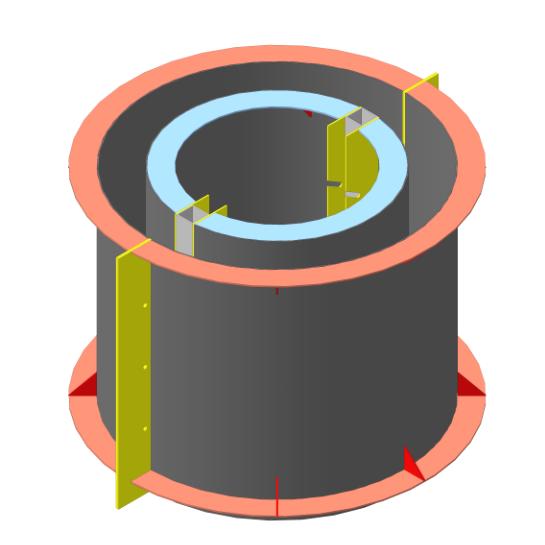

As can be seen from the figure, the casting mold consists of two half-rings made of strong sheet steel (1.5-2 mm). Stiffeners are welded to the ends, and connecting plates are attached along the entire length, which, before concreting, tighten the half-rings into a single structure.

It is not difficult to remove the formwork from the outside of the form: unscrew the bolts and tap the walls with a hammer. The inside is harder to remove. Here, to facilitate disassembly, two additional narrow walls or square pipes are placed in the mold.

After knocking them out, the inner parts of the "shell" are removed from the ring.

Why use fine aggregate for concrete? Because the thickness of the standard ring is small (7-9 cm). It is impossible to pour large crushed stone into the mold, since the structure of the concrete will turn out to be uneven.

Vibration compaction also plays an important role. Without it, it will not be possible to remove air bubbles and shells that reduce the strength of concrete. By bayoneting the sealing problem can be solved, but only partially. If you do not have a platform vibrator, then you can use a regular hammer drill. Instead of a peak, it is necessary to clamp a piece of reinforcement with a thick steel plate welded to its end.

Turn on the tool and consistently press it from the outside into the lower and upper parts of the mold. The vibration through the metal is transferred to the concrete. It will begin to sag and thicken.

To raise and lower the rings with a crane, do not forget to install 4 mounting loops in the mold (wire diameter 8-10 mm). Bend their ends and bury them in concrete by 40-50 cm.

Which manufacturer to choose

Concrete rings for wells are produced by about 250 companies located throughout Russia. Consider 5 proven manufacturers.

-

OOO "MasterStroy" The company is located in Voskresensk, near Moscow, specializes in the sale of bulk and bulk cement, is engaged in the manufacture of pressure pipes and reinforced concrete rings.

-

JSC "Plant of industrial construction details". The company has been known in the construction market for over 45 years; it is one of the largest manufacturers of reinforced concrete products in the Tyumen region. The company has its own construction laboratory (accredited), which controls the quality of products.

-

OOO "Monolith Stroy" The company is located in the Moscow region, has been manufacturing and selling reinforced concrete products since 2007. The product range includes bridge and composite piles, FBS, wall rings, bottom plates and manhole covers.

-

LLC "GazoBloki" This is a Voronezh company engaged in the production of ready-mixed concrete, silicate and facing bricks, concrete rings and additional elements for them.

It should be clarified that these are far from the only suppliers of the Russian region. The above companies strictly monitor the quality of their products, work directly with suppliers of raw materials, and comply with GOST standards.

Production technology

Rings are made for wells from hard concrete, which is poured into the formwork. It is necessary to clarify that reinforcement is made of steel wire with a diameter of 8-12 mm. At opposite ends of the structure, two vertical rods are installed, which act as lugs for lifting the ring.

The mold is compacted by vibration to eliminate the formation of voids. The formwork is removed one day after the concrete is poured. After that, finished products are stored in open areas. The release strength of the ring (50% of the specified) is gained after about 7 days. The full strength of concrete is achieved after 28 days.

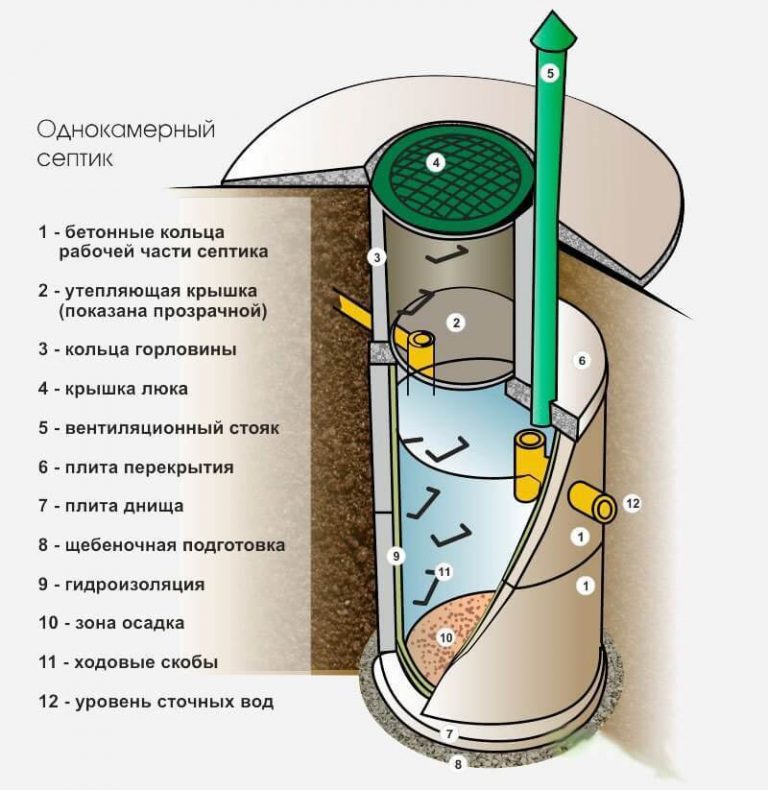

Schemes of sewerage from concrete rings

Treatment facilities consist of 1-3 chambers. The choice of quantity is influenced by:

The design of a single-chamber septic tank

- permanent or seasonal residence;

- the number of family members and discharged effluents;

- financial opportunities.

The simplest device is 1 container with sealed walls and a bottom. Drains accumulate in it, which are removed by a sewage machine. The frequency of service calls depends on the volume of the tank, the intensity of operation, the number of sinks. The sooner the well fills up, the more often you have to turn for services. The scheme is mainly used in cottages with seasonal residence or for a family of 1-2 people.

Anaerobic septic tank consists of 2, rarely 1 chamber. In them, effluents decompose anaerobic bacteria that do not require oxygen. There is no need to pump out with a cesspool machine.The scheme provides for post-treatment in a filtration well without a bottom, a trench or in an aeration field.

The water goes into the ground. The simplicity of the scheme and energy independence made the device in demand among rural residents. The only inconvenience is the need to periodically remove crushed stone, sand from the filtration devices, and replace them with new ones.

An aerobic septic tank is 2-3 chambers for complex wastewater treatment. Anaerobic microorganisms work first, then aerobic microorganisms, which are supplied with oxygen by a compressor. Purification reaches 95%, it is allowed to dump drains directly onto the surface of the soil, into a reservoir, use them for technical purposes, and water the garden with them. Aerobic bacteria cannot live for a long time without oxygen, therefore, if the compressor does not work for 2-3 days, they die. This factor should be taken into account in case of frequent power outages.

Scheme of an anaerobic septic tank

Advantages and disadvantages

In addition to the characteristics of strength and durability, the advantages of use include such features as:

- speed of installation (when compared with brick laying), despite the need to use auxiliary lifting equipment;

- relatively affordable cost for any reinforced concrete product;

- convenience in the device with a snug fit and connection of products with a lock without gaps;

- service life, can be more than 50 years.

The disadvantages include the following important points:

- a rather time-consuming installation process with the obligatory involvement of lifting mechanisms and additional labor;

- difficulties in transportation;

- with unskilled installation, the walls may begin to disintegrate after a period of 5–6 months;

- if the operating rules are not followed or in case of untimely measures for waterproofing the walls of concrete wells for sewage, the concrete surface may collapse, and the reinforcing mesh installed inside the products is subject to corrosion and deformation.