Wiring diagram for the bathroom and bathroom

When performing plumbing work in these rooms, 3 methods of distributing metal-plastic pipe products can be used.

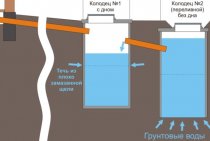

Serial connection system. This option provides for the connection of each plumbing fixture to the main pipe using a separate tee. It is relevant for baths in which there is a minimum number of objects (faucet, washing machine). It is possible to implement a sequential scheme after the completion of the finishing work in the room by open laying. The assembly process looks quite simple: the pipe is laid from object to object, and the supply element is simultaneously removed from the tee.

Wiring with pass-through sockets. Here the technique is similar, only sockets are used, not tees. Such a scheme is most widespread in private homes, since it involves laying pipes of great length. Here you need to know that to provide the necessary pressure, you will need to install an additional pump.

With a consistent wiring diagram, the water supply system can be laid openly, without chasing the walls for pipes and water sockets

Efficient collection system. This practical and reliable option involves connecting to the central pipe of each object through a supply pair. The collector for metal-plastic pipes allows you to turn off or regulate the water supply to a single plumbing fixture. The collector is placed together with the control devices in a special cabinet. Such a technical solution has the following advantage: if one of the objects (faucet, washing machine) fails, there is no need to completely disconnect the bath from the water supply - just turn off the corresponding stopcock.

Installation of water sockets

Water outlets can be installed:

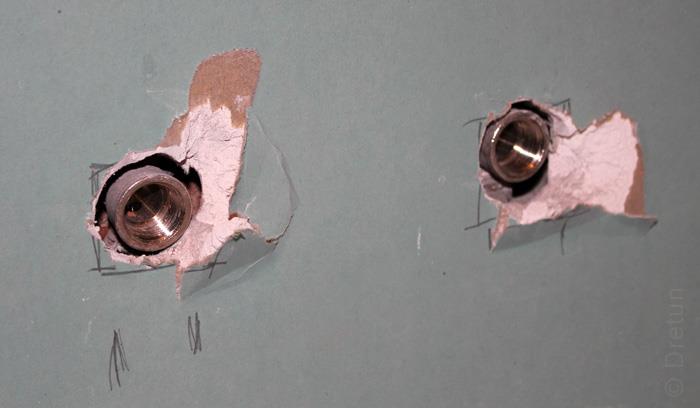

inside the wall. This method is used when installing equipment before the final finishing of the room (under tiles) or in a plasterboard wall. Concealed installation allows you to hide the water supply pipes and the main part of the fitting and achieve a more pleasant view of the room;

Installation of water outlets under drywall

on the surface of the wall. Surface mounting is used for a sink, faucet or other equipment where flush mounting is not possible.

Installing a water outlet on a wall surface

Regardless of the installation method, it is recommended to use the following scheme:

- markup. At the first stage, it is necessary to determine the place of attachment of the water outlet, which corresponds to the location of the mixer, faucet or other connected equipment;

Location determination

- wall chasing. Work is performed only when choosing a hidden installation method for the fitting. If surface installation is preferred, then this item should be skipped;

Preparing niches for placing pipes and fittings

- fitting fastening. The water outlet can be fixed to the wall in one of the following ways:

using self-tapping screws. This method is the most durable. To fix the water outlet with self-tapping screws, it is necessary to drill holes, insert a dowel into each hole, and only after that fix the water outlet;

Fixing the water outlet with self-tapping screws

using sand-cement mortar. This mounting method is only suitable for flush-mounted equipment. The fixation is strong;

Fixing the water outlet with cement mortar

with mounting foam. This method is also only suitable for hidden wiring;

Fixing the fitting on the mounting foam

- checking the correct installation of equipment;

To connect a faucet or other equipment, it is important that the outlet outlets are located at the same height from the floor and along the same axis. You can check the correct installation using a building or laser level.

Determining the correct installation of the water outlet

- connecting a water outlet to water pipes.

After completing the specified list of works, niches are sealed, with hidden installation of equipment and connection of a mixer, faucet, and so on.

For more information about the process of doing the work with your own hands and the rules for installing equipment, you can see the video.

Varieties

The classification of water outlets is based on a number of criteria. Let's consider them in a little more detail.

1. Scope of application. According to this criterion, water sockets are:

- for cold water supply;

- for hot water supply;

- for heating.

The last two types of water outlets are similar in many ways.

Another thing with cold water systems. They are created using fittings for metal-plastic pipes made from plastic that does not lose its strength properties at a temperature not exceeding +30۫С.

2. Material of manufacture. Water outlets are made from:

- galvanized cast iron;

- brass and bronze;

- of stainless steel.

Water sockets are made of steel, brass, bronze, PVC, polypropylene, and can also be combined

In addition, advances in the field of polymer technology have created the prerequisites for the production of such elements from PVC or polypropylene. This was mentioned above.

3. Configuration and shape of connectors. According to this criterion, water sockets are of the following types:

- with a short or long strap for fastening;

- with three and two mounting holes;

- single and double.

Installation and installation

As for the connection of the fitting to the water supply system, all the main options have been considered, and now it is worth paying attention to the connection of the water outlet to the wall, and to be more specific, the installation and installation of its structure. The simplest mounting option is visible, but it is not recommended to use it, due to the extreme non-aesthetics and special requirements for the base to which the water socket is attached

Therefore, hidden mounting options are more often used, among which there are three technologies:

The simplest mounting option is visible, but it is not recommended to use it, due to the extreme non-aesthetics and special requirements for the base to which the water socket is attached. Therefore, hidden mounting options are more often used, among which there are three technologies:

• In the pocket.

• On the lining.

• Mixed.

The first option is used when the wall has a sufficiently large thickness and the creation of a recess in it will not bring much harm. For example, in the case when it is concrete or brick floors. In this case, the recess is made to the full width of the fitting, i.e. not less than 40-50 mm.

If it is impossible to go deep into the wall, as in the case of plasterboard partitions, the reverse method is used - building up or creating a lining. In this case, a lining is installed in a niche created on the basis of a wooden or metal frame sheathed with plasterboard. A fitting is mounted on it, and after that the whole structure is hidden under a drywall sheet, which is installed flush with the output fasteners. Such a mixed option will achieve an aesthetic balance.

If there is no need for a hidden installation, you can get by with a simple installation on a wooden lining processed according to the rules, to which the water socket will be attached through mounting holes.

Tip: when installing, be sure to check with the help of the building level the correspondence of horizontals and verticals, for optimal results.

As for the holes themselves, depending on the design created by the manufacturer, there can be from two to five. In this case, anchor dowels can be used as fasteners, and in their absence, a cement-sand mixture or mounting foam.

Types and types of water sockets

Water socket (VR) - a type of fitting for water pipes, which, on the one hand, has a standard connector for connecting to a pipe (depending on the type of pipe), on the other hand, a threaded connection to which a mixer eccentric or a water supply hose is attached. BP is distinguished by the material, the shape of the connectors and the configuration.

For the manufacture of VR use:

- stainless steel;

- galvanized cast iron;

- brass and bronze;

- PVC and polypropylene.

Stainless steel BPs are quite expensive, the average price of one fitting is 800 rubles. Working pressure - 10-20 atmospheres.

To connect stainless steel BP to copper pipes, brass adapters are used. Connection to plastic and metal-plastic (metal-polymer) pipes is performed without adapters, using a compression sleeve or a tightening nut (depending on the type of connector). Connection to a corrugated stainless pipe is possible only for BP with a connector designed for such installation or through an adapter. Therefore, before buying, check the type of connector.

VR made of galvanized cast iron are cheaper than stainless steel, the average price is 200 rubles. According to the technical parameters and connection, it is similar to the BP from stainless steel. If the protective layer is damaged, it will rust.

BP made of brass and bronze are even cheaper, the average price is 100 rubles. This type of VR is used more often than others. According to the technical characteristics, it is not inferior to BP made of stainless steel. To connect to copper and steel pipes, no adapter is needed (if the connector matches). The main types of connectors are compression and crimp.

PVC and polypropylene VR are the cheapest, the average price is 40 rubles. PVC fittings are used to connect plumbing fixtures to cold water supply (CWS), because the maximum temperature recommended for these BP is 40 degrees. Polypropylene fittings are used for cold and hot water supply (DHW). In terms of working pressure, they are similar to BP from stainless steel. Installation is carried out by soldering.

Do not use PVC for installation on polypropylene pipes and vice versa. These materials are incompatible when soldering.

Plastic water sockets

BP configuration

Single BP with 2 fixing holes. Used to connect adapter hoses. Therefore, depending on the model, they are cut with external or internal threads of various diameters. With a hard connection of mixers, there is a high probability of damage to the fasteners. It is possible to mount multiple BPs on a mounting plate to reduce the number of holes in the wall.

Single BP with 3 mounting holes. Used to connect adapter hoses and faucets. Depending on the model, the fittings have external or internal threads of various diameters. Additional fastening from above increases the rigidity and strength of the connection. Installation on a mounting plate is possible; to install a mixer, the bar is fixed with 4 or more anchor dowels.

Double BP on a short bar is used to connect adapter hoses. This reduces installation time. Application for connecting mixers is not possible, due to the large difference in the distances between the installation points and the BP thread.

Double BP on a long bar is used to connect adapter hoses and install mixers (for this, a bar with two rows of holes for fastening is used, top and bottom). The use of such BP facilitates the installation and connection of plumbing, because the distance between the BP corresponds to standard faucets.

Brass water sockets on the mounting plate

Connection types

The classification of water outlets by type of connection is the most extensive

It is directly related to the options used to create the fitting materials, but these are just details of the range of manufacturing companies, so you should pay attention to the types of connection with the main pipe.

They can be self-locking, crimp, threaded, and even press-fit. Each type of connection has many features that make them more or more attractive in terms of operation and installation. They are most evident in the example of crimp water sockets.

At the heart of their connection is a special sleeve, the so-called collet. It has a cylindrical shape and is clamped between the outer and inner parts, due to which it gives the desired tightness. The undoubted advantages of this connection:

• The modernity of the method.

• Relatively low cost.

• Easy to install.

• Widespread.

• Tightness.

• Possibility of reuse.

An older version of the connection is threaded. Its main disadvantage is the need to comply with operating conditions, since the alternate increase and decrease in the temperature of the water passing through the water supply system can significantly reduce the tightness of the connection.

On the other hand, there are many advantages:

• High impact strength.

• Easy to dismantle and reuse.

• Durability.

As for press water sockets, they have a more serious drawback.

They cannot be installed without special equipment, and besides, such a connection is non-separable, so it will not be possible to dismantle and re-install such a fitting. They are connected to the supply water supply by soldering, which is the main difficulty in their use.

At the same time, they are quite inexpensive, versatile, compact, and most importantly, durable.

Important: polypropylene and PVC elements are incompatible with each other, and when soldering they will not give a tight connection. The last, but rather the time of appearance option - self-locking fittings

The last, but rather the time of appearance option is self-locking fittings.

This version of water sockets is a complex structure with a connection based on internal rings, including toothed ones, which are responsible for connecting the elements.

Their main advantage is the trouble-free repeated installation and dismantling of the product, as well as its reuse.

Design features

For the installation of modern water supply systems, metal-plastic pipes and fittings are often used. This material is non-corrosive, durable and easy to install and maintain. Connecting elements appropriate for their purpose are selected for such systems: tees, press connections, etc. No less popular are polypropylene, PVC and other pipes, fittings for them are also available in a wide range.

Different types of pipes are used for water supply, fittings for them are plastic or metal

As for the water outlet, it acts as a fastening of the outlets of the plumbing system to the wall and connecting them to the taps. A feature of this element is that its design includes a mounting plate and a fitting-adapter (socket). A fastening bar is usually made of steel due to its higher strength compared to similar samples of metal-plastic or plastic. On this part itself there is a connector in the form of a coupling. It has a thread on one side. for connecting the water supply hose or a mixer, and the other side it is connected to the water supply system.

Installation of water sockets

To carry out this operation, the following methods have been developed:

- hidden (hidden) on anchor dowels.

- hidden on a cement-sand mortar;

- hidden on mounting foam;

- surface mounting plate;

- surface anchor dowels.

In the first three cases, the water outlet is installed in the strobe, which was created for the pipe itself. Thus, only the upper part of the part with a threaded connection protrudes from the wall. When implementing this method, special requirements are imposed on the dimensions of fittings for metal-plastic pipes. This is due to the fact that there is a certain distance between the bottom of the strobe and the water outlet. This parameter is adjusted using wedges - homemade wooden stands. Meanwhile, with a secret method, the use of water outlets of any configuration is allowed.

Fastening with anchor dowels is carried out in the following sequence:

- the water outlet is connected to the pipe;

- attaching this fitting to the bottom of the strobe, mark the attachment points;

- drill holes, the diameter of which must match the value of this anchor parameter and a depth of 3 mm greater than the length of this fastener;

- attach the water socket to the wall, align its mounting points with the holes;

- insert anchor nails, then hammer them in.

The method of fixing water sockets depends on the material of the wall and the method of laying the plumbing system.

The above sequence of actions is performed for both types of installation with anchor dowels - hidden and surface.

Make a hidden installation of a water socket on a mounting foam as follows:

- clean the bottom of the strobe;

- determine the size of the wood spacer. Its thickness should not be more than 1 mm;

- connect the water outlet to the pipe;

- moisten the bottom of the strobe and apply a layer of mounting foam 1 cm thick according to the size of the fitting:

- insert the gasket and press firmly;

- apply the same layer of mounting foam already on the gasket, press the water socket to it and fix it in the pressed state. Excess foam is cut off after an hour.

Installation on a cement-sand mixture, start by connecting the water outlet to the pipe. Then adjust the distance between this fitting and the bottom of the strobe. Then securely fasten the water outlet. It is best to do this by inserting a wooden or metal rod at a distance between this part and, for example, the opposite wall. Having done this, cover the fitting and cracks with the solution. After two days, remove the spacer, grind the surface and sand it. Cement-sand mixture with water is prepared in a ratio of 3:1. It should not pour out of the strobe.

A water socket is a mandatory attribute of the water supply system of a house or apartment. Being rigidly fixed, it protects engineering communications from vibrations that occur during the operation of household plumbing devices.

Types and classification

As for the species classification of water sockets, it can be conditionally divided into three types:

• According to the materials used in the construction.

• By design features.

• According to the type of connection being established with the main water supply pipe.

As for the materials used in the production of water sockets, there are a lot of them. Conventionally, they can be divided into three basic groups:

• Non-ferrous metals.

• Black metals.

• Polymers.

The former includes predominantly alloys such as bronze and brass, but pure non-ferrous metals such as copper can also be used. The second group includes cast iron and steel. And here, the third - the most extensive. It includes a huge number of polymers, the main of which are PVC - polyvinyl chloride, PET - polyethylene, as well as polybutene and polypropylene.

All of them need to be used with appropriate pipes, so polyethylene water sockets will only be compatible with plastic pipes, but there are some tricks that can be applied when installing dissimilar components to create a water supply system.

How to choose a water outlet

To choose the right water outlet for a faucet, faucet, washing machine or other equipment, the following factors must be considered:

- fitting material;

- device type;

- method of connection with the equipment;

- manufacturer.

What materials are water outlets made of?

Water sockets designed for installation both in the bathroom and in any other place can be made:

- from brass. The most popular material, characterized by strength, inertness to chemical impurities, resistance to temperature and pressure changes, as well as low cost;

- from stainless steel. A more expensive material that has properties similar to those of brass water sockets;

Water sockets made of stainless steel are not recommended for installation on systems with an internal pressure of more than 20 bar.

- from cast iron. The material has a high margin of safety, which allows the use of fittings on pipelines with a high level of pressure and fragility. We install water sockets made of cast iron in an exclusively hidden way, this will prevent any mechanical impact;

Cast iron fitting for plumbing systems

- from plastic. Plastic sockets are absolutely inert to chemical attack, can withstand high temperatures and pressure, and are characterized by minimal cost. It is recommended to use for polypropylene pipes, PVC pipes or metal-plastic pipes;

Plastic fitting for connecting plumbing

- from copper, bronze and other similar metals. Expensive fittings, characterized by a maximum margin of safety under any circumstances. It is recommended to install on pipes made of similar material.

Types of fittings

After determining the material of manufacture of the fitting, you can proceed to the selection of the model.

Water outlets can be:

- single (pictures above). Used to connect one source of water intake or heating tap;

- double.

Double water socket can be designed:

for connecting two water intake points to one pipe, for example, for connecting a tap and for a washing machine;

Water socket with one connection and two outlets

for connecting one piece of equipment to two pipes, such as a faucet in the kitchen or bathroom. Such equipment is supplied on a support bar. The bar for water sockets can be cast or composite.

Double water socket on a composite bar

Connection methods

Water sockets can be equipped with the following systems for attaching to pipes and plumbing fixtures:

threaded (pictures above)

Threaded fittings are easy to install, low cost and reusable, which is especially important for repair work; To achieve a tight connection when using a threaded fitting, it is recommended to use special sealing materials, which include FUM tape, linen thread, and so on.

To achieve a tight connection when using a threaded fitting, it is recommended to use special sealing materials, which include FUM tape, linen thread, and so on.

crimp. Fittings are distinguished by a high level of tightness, which is achieved due to the presence of an additional element in the device - a crimp collet fixed with a nut;

Compression Fitting

Press. Pipes are fastened to the press water socket using special equipment. Among the advantages can be noted a high level of tightness and resistance to high pressure, which allows the use of fittings in specialized plumbing or heating systems.

Fitting with press fastening equipment

Manufacturers

An important aspect when choosing a water outlet is to determine the manufacturer that produces reliable and durable fittings.

These manufacturers are:

- Valtec (joint Russian-Italian production).Advantages - low cost, adaptability to Russian systems, high quality.

- UNI-FITT (Italy). Fittings are made from high quality raw materials. Quality control of products is carried out at all stages of production, which makes it possible to obtain reliable components for plumbing and heating systems.

- Rehau (Germany). Rehau is a popular brand in the Russian market, characterized by a high degree of reliability and a long service life.

- Uponor (Finland). The company specializes in the manufacture of high-strength plastic fittings for sinks, bathtubs and other equipment.

Use and maintenance

Often users of water supply systems are not even aware of the existence of water outlets, since they are usually hidden from the user. And for the first time they encounter them only because they have to replace the faucet in the bathroom or in the kitchen.

The water outlet works quite simply. It transmits the pressure of the liquid from the supply water main directly to the faucet, faucet or other plumbing device. The most commonly used pair is a mixer and a water outlet. But in any combination, you should follow the basic installation rules.

Firstly, the installation of such a fitting is carried out at the end of the finishing of the premises. Secondly, it is necessary to observe the distance between the fittings if a pair is installed, so installation at a distance of 15 cm is considered the standard. Thirdly, if the presence of fastening is masked, it is necessary to keep the notches of the hardware visible, which will allow, if necessary, to carefully dismantle the product.

Finally, we note that even if some errors were made during the installation of the water outlet, they can be leveled by using an eccentric or a flexible water supply hose during further installation.

Water sockets are used for rigid fastening to the wall of the outlets of the water supply system and connecting taps and other plumbing fixtures to them.

From the article you will learn about the types and purpose of water outlets, the advantages and disadvantages of specific models and learn how to install them.