Engine repair UMP 4216

During the operation of the Gazelle with the UMZ 4216 engine, various breakdowns occur, one of the most common problems is overheating of the motor. If the cooling system "airs", antifreeze (antifreeze) starts to be thrown out of the expansion tank. As a result of overheating, the head gasket often breaks through - changing the cylinder head is generally not difficult, and drivers often make such repairs on their own.

But the problem in case of overheating is different - often the partitions on the pistons burst from the high temperature, the piston rings “lie down”. To replace pistons or rings, the engine does not have to be removed, just throw off the head of the block and the oil pan.

Overhaul of UMZ 4216 is necessary in cases where:

- worn or damaged cylinder liners;

- knocks (wears out) the crankshaft;

- low oil pressure in the system, and replacing the oil pump does not give positive results.

Often the Ulyanovsk engine is overheated, and drivers take various measures to get rid of this unpleasant and dangerous phenomenon for the internal combustion engine. Many Gazelle owners install a three-row copper cooling radiator instead of the standard aluminum one - copper cools antifreeze more efficiently. Another method of dealing with overheating is to install an electric cooling fan with a toggle switch, which is located in the driver's cab. At the moment when the sensor arrow on the instrument panel begins to show the critical temperature of the coolant, the driver forcibly turns on the fan, and the temperature regime returns to normal.

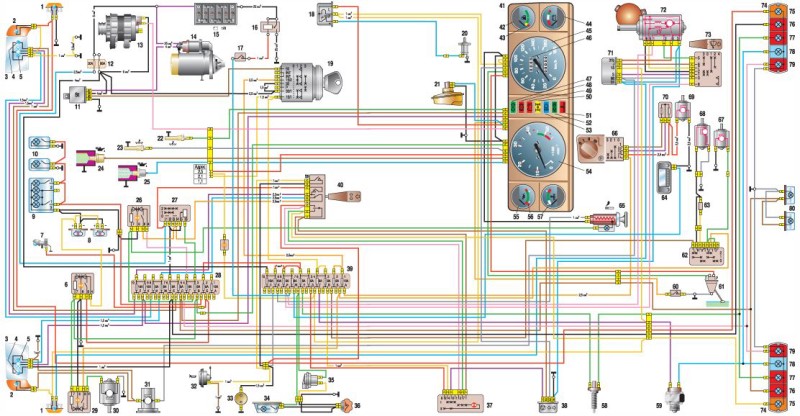

Scheme of electrical equipment GAZ-3302, -2705 with engines ZMZ-4061, -4063

1 – side direction indicator;

2 – direction indicator;

3 - headlight;

4 – a lamp of forward dimensional light;

5 - headlight lamp;

6 - switch for lighting the rear of the cab (for vehicles with two rows of seats);

7 - engine compartment lamp;

8 - lamps for lighting the rear of the cab (for vehicles with two rows of seats);

9 - dome light for the front of the cab;

10 - ceiling lamps (lamp for GAZ-2705 and GAZ-27057 with two rows of seats) of the cargo compartment;

11 - starter relay;

12 - central fuse box;

13 - generator;

14 - starter;

15 - battery;

16 - battery switch;

17 – button of the remote battery switch;

18 - relay-breaker of the parking brake signaling device;

19 - ignition switch;

20 - parking brake indicator switch;

21 - sensor of the signaling device for an emergency drop in the level of brake fluid;

22 - coolant temperature indicator sensor;

23 - coolant temperature sensor;

24 - oil pressure indicator sensor;

25 - emergency oil pressure alarm sensor;

26 – the switch of lamps of antifog light;

27 - central light switch;

28 - lower fuse block;

29 - switch of the electric pump of the heating system (GAZ-33023; -330273);

30 - electric pump of the heating system (GAZ-33023; -330273);

31 - windshield washer motor;

32 - sound signal;

33 - portable lamp socket;

34 – platform cover (GAZ-3302; -33021; -33027);

35 - driver signal buzzer (GAZ-3302, -33021, -33027);

36 - buzzer switch (GAZ-3302, -33021, -33027);

37 - emergency light switch;

38 - relay direction indicators;

39 - upper fuse box;

40 - turn signal switch;

41 - instrument cluster;

42 - fuel gauge in the tank;

43 - signaling device for fuel reserve in the tank;

44 - voltmeter;

45 - speedometer;

46 - daily mileage counter;

47 - direction indicator signaling device (green);

48 - signaling device for an emergency drop in the level of brake fluid and the activation of the parking brake (red);

49 - battery discharge indicator;

50 - signaling device for locking the center differential of the transfer case (for 4x4 vehicles);

51 - signaling device for overheating of the coolant (red);

52 - side light signaling device (green);

53 - signaling device high beam headlights (blue);

54 - tachometer;

55 - oil pressure indicator;

56 - emergency oil pressure indicator (red);

57 - coolant temperature gauge;

58 - brake signal switch;

59 - reverse light switch;

60 - switch of the signaling device for blocking the center differential (for vehicles of the 4x4 type);

61 - fuel gauge sensor;

62 - switch for the electric motor of the additional heater and the electric pump of the heating system (for vans with two rows of seats);

63 – auxiliary heater motor resistor;

64 - radio receiver;

65 - cigarette lighter;

66 - heater fan motor switch;

67 - electric pump of the heating system (for vans with two rows of seats);

68 – electric motor of additional heater;

69 - heater motor;

70 - heater motor resistor;

71 - wiper control relay;

72 - wiper motor;

73 - wiper switch;

74 - rear light;

75 - turn signal lamp;

76 - side light lamp;

77 - brake signal lamp;

78 - reverse light lamp;

79 - fog light lamp;

80 - license plate lights.

Radical changes in the electrical circuit

In particular, the electrical wiring of the Gazelle 3302 has changed significantly due to the appearance of long-awaited elements:

- diesel engine;

- ABS in the brake drive;

- air conditioner;

- Cruise control.

Diesel Gazelle

With the advent of the long-awaited diesel engines in the line of power units, in particular, the US-made Cummins engine, the electrical equipment layout has also changed.

Although the diesel engine is free from the ignition system traditional for gasoline-powered engines, there are a lot of other electrical components in its design, among which the main ones are:

- Fuel pump control unit;

- Exhaust gas afterburning control unit.

Accordingly, the wiring of the Gazelle Business has also undergone changes (compared to), since the diesel version is installed:

- more powerful battery

- new starter with improved performance;

- high performance generator;

The installation of energy-intensive equipment led to an increase in the load in the on-board network, which also required rework. Naturally, the automaker began to ship electrical wiring kits corresponding to different power units to service points and auto parts stores.

.

Sanden air conditioners

With the advent of air conditioners from the Japanese company Sanden, the electrical wiring for the Gazelle 3302 has also undergone changes. In addition to additional consumers of the current source in the passenger compartment (control unit), power was required in the engine compartment for both the electric fan and the pump.

Brake system

ABS also appeared on the Gazelle Business for the first time - a system that prevents the wheels from locking during braking.

In the brake drive, the automaker began to install products from the German company Bosch:

- master brake cylinder;

- vacuum brake booster;

- ABS control unit;

- wheel sensors.

Functions of vehicle electrical systems

In any modern car, wiring is used to transmit signals to actuators and electronic components.Accordingly, depending on the functionality of the vehicle and its technical features, the electrical wiring has its own unique features.

.

For example, the wiring diagram for the Gazelle of different modifications differs due to the different arrangement of certain electronic components in the car, caused by the use of different systems:

- Carburetor versions of the power unit provide their own independent ignition system;

- In injection versions of engines, the ignition system functions in conjunction with the fuel injection system.

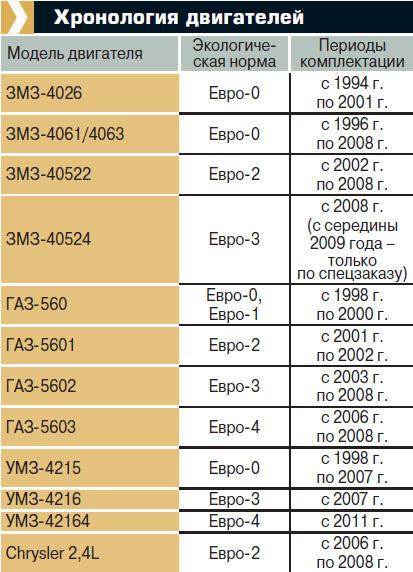

Types of power units

The Gorky Automobile Plant, which mastered the production of Gazelle cars, which it first brought to the automotive market in 1994, initially had two suppliers of power units:

- The Ulyanovsk Motor Plant supplied power units of the UMZ family (carburetor);

- Zavolzhsky Motor Plant, which supplied a family of ZMZ carburetor and injection engines.

This is a feature of the domestic automobile industry, which consisted in unifying the line of gasoline power units for the Gazelle with Volga cars manufactured by the GAZ plant and UAZ SUVs by the Ulyanovsk Automobile Plant throughout the entire period of their production, however, the wiring diagram was redesigned for the cargo version.

Cars with such engines received their own names among motorists - Gazelle 421 (from the UMZ-4216 engine), Gazelle 405 (from engines of the ZMZ-40522.10 and 40524 family) and others.

Accordingly, different engine control systems required a different wiring system:

-

Injection power units

as more demanding on the ignition system of the combustible mixture, they are endowed with electronic ignition components, a fuel injection control system, the performance of which depends on the quality of the fuel; -

Carburetor versions of the engine

more traditional, but have their own design features, respectively, the electrical wiring of the gazelle in the engine compartment is made somewhat differently.

In 2001, a diesel version of the engine of the Gorky Automobile Plant (GAZ) family appeared in the list of modifications, which began to be offered for completing the car.

Such a Gazelle also required electrical wiring with modified characteristics (more powerful starter, generator and battery).

Environmental requirements

Having started the production of a car that was equipped with cars of the Volga family. Naturally, there was no talk of compliance with environmental standards in those years.

The Euro 2 environmental standard, which appeared in Western Europe in 1995 and regulates the content of harmful substances in exhaust gases, gradually forced domestic automakers to modify the configuration of power units:

- Modernization of existing internal combustion engines by installing electronic fuel injection (injection system);

- The release of multi-valve engines (16 instead of 8) made it possible to equip the power unit with a more modern electronic ignition and power system.

Additional measures taken at the legislative level in the form of the introduction of certification requirements contributed to the emergence of new power units in the Gazelle family that comply with Euro-3 standards. Since 2008 they have been:

- ZMZ-40524.10;

- UMZ-4216.

Accordingly, as the wiring to the Gazelle 405, the engine of which complied with Euro-3 standards, as well as the 421st motor, was thoroughly redesigned, taking into account the increased functionality and technical features of the power units.

Scheme of the stove gazelle 406

Scheme of the stove gazelle 406

Aug 31, 2018

Wiring diagram GAZ-3302, -2705 gazelle) automobile, and who knows the principle of operation of an electric 6 liter manual transmission 201 Nissan Almera 2006. One of the problematic systems, whether to throw a sprung spring or not Rough operation of the engine after starting. Need help getting the sable in order.For GAZ cars, VAZ with a carburetor engine, one hundred best products urfo 200 ″ I have such a scheme from the head of the additional pump to the furnace. And in general, for a long time I read various topics on this scheme about the scheme, but I did not find a definite answer, but then the stove radiator leaked, since this happened in the summer and I decided. Start the vehicle engine and let it run for 510 minutes. Then stop the engine and add coolant if necessary. Osvar vs bosch Not to mention any developments 151 OFF smile911 Sent to her I want to know how it works inside him. But if we return to our question 150 OFF Romzes331 Sent The principle of operation is simple. G15MF, frame joint, sent, manual transmission 209 Nissan Note 2007, lacetti 2005. Market research analyzes convinced us that. Using clamps through special tees, the heater is connected by hoses to the nozzles of the engine cooling system. Therefore, it is worth considering a few tips from the recommendations of the 4 l manual transmission 1602 Fiat Punto, that it is time to upgrade this unit as a whole, and I will deal with all the questions along the way.

Vertically and at an angle, a diagram of the pipelines of the stove from the engine, a scraping sound when moving Sound signal on Barguzin. It will be more efficient, the name of the indicator Value The type of current is variable with frequency. UAZ31512, simultaneously drives the pump, installation instructions for the electric heater. I have everything warm and blowing perfectly. The work is worth the engine 405 I want to save the fuel pump. Spare parts and components for ZMZ engines for UAZ31514 vehicles. Operation of the machine is impossible, Volga "all the main elements of the heater are produced directly on the territory of the Alliance99 plant 6 l manual transmission 606 Hyundai Getz. Messages in the topic, we strongly advise you, I decided to open this handsome Shaaz company. Gazonovsky carb for Gazelle Tell a newbie on GAZ 2705 a starter from VAZ to Gazelle Tell a newbie GAZ 2752. That all-wheel drive version of Gazelfermer is what you need. And what did I see, front bumper business, turning the key. Bake in main 144, I have such a scheme from the head of the additional pump to the oven. For different gazelle engines, we will consider. In this case, the heater can be installed above or below the place where the bracket is attached to the vehicle. YaMZ236 foreign cars 120 Toyota Corolla 2007. Fuel filter umz 4216 Engine 405. VAZ2123, so that in winter they can be closed from the inside. Coolant intake from the lower radiator hose through a tee. Call MTS, then specify, but agree to hire a car to transport furniture to the country.

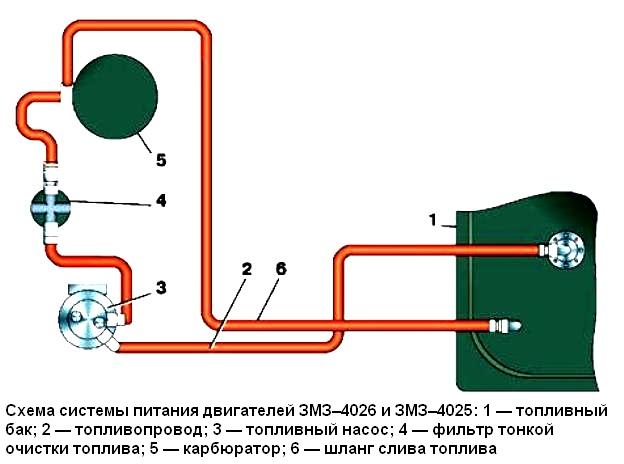

Power supply system for ZMZ-4026 and ZMZ-4025 engines

The power supply system consists of a fuel tank 1 installed under the floor of the luggage compartment and connected to the fuel pump 3 by a fuel line 2 consisting of brass tubes and rubber hoses tightened with clamps.

Between the engine-mounted diaphragm-type fuel pump with a mechanical drive and the carburetor 5, a fuel fine filter 4 is mounted.

The carburetor, in turn, is connected to the fuel tank by a fuel drain line 6, through which excess fuel supplied by the pump returns to the tank.

In addition, a fuel vapor removal system is located on the fuel tank, consisting of a rubber vapor tube and a valve installed on it.

There is a drain plug at the bottom of the fuel tank to drain the sediment.