The creation of a drywall construction begins with the construction of a strong and durable frame. In most cases, when choosing a material for it, preference is given to galvanized steel. Let's find out how to choose the right components of the metal frame - a profile for drywall and fasteners to it.

Types of metal profile

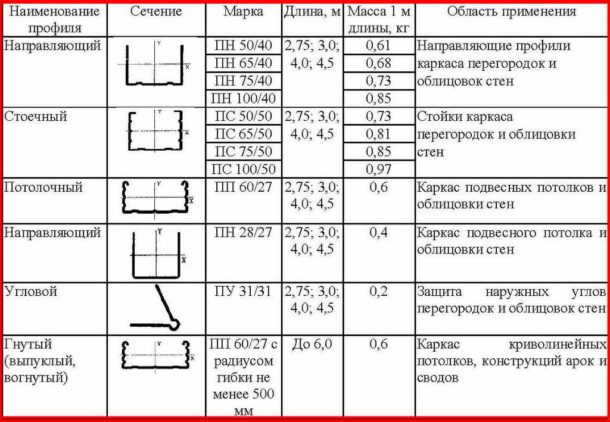

The number of options for GKL structures is huge, which required the creation of a wide range of metal profile types. They can be divided into several types:

- Depending on the place of use - on the ceiling and wall.

- According to the role performed - on guides and carriers.

- According to the nature of the structure being erected - on profiles for cladding walls and ceilings or constructing partitions.

- Depending on the cross section - into angular, flat and U-shaped.

All profile types are shown in the photos below.

When installing gypsum boards, various combinations of metal profiles are used, depending on the configuration and purpose of the structure. The parameters and types of parts, as well as the process of their manufacture, are regulated by TU 112000-001-12586100-2009, TU 1121-012-04001508-2011, TU 112000-002-94835001-2013. They are made of galvanized steel (GOST 14918, 14918-80, 52246-04, R 52246), sheet rolled steel (GOST 1050-88), galvanized roll with a polymer coating (GOST R 52146).

Profiles for the frame when leveling the wall

When carrying out such work, two main types of metal profiles are used: guide and rack.

Guide profile for wall cladding

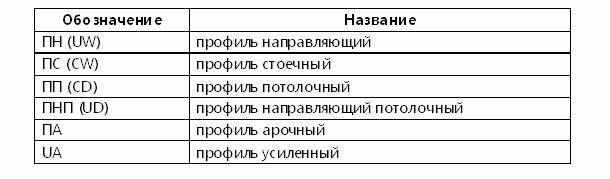

To align the bases, a guide metal profile is usually used, marked with the letters PNP or UD, which is also called the starting one. Its purpose is to form the perimeter of the future wall structure, on which the racks will be attached. Therefore, this type of profile is made of thick steel and has the following overall dimensions:

- Standard length is 3,000 mm. At the request of customers, construction stores are ready to supply elements up to 6 meters long. However, if necessary, these details are built up by overlaying.

- The height of the side wall (shelf) is 40 mm.

- The width of the backrest can vary: 50, 65, 75 and 100 mm backrest rails are available.

To fix the guides to the wall, floor, ceiling, holes with a diameter of 8 mm are pre-drilled in their back. If the pitch of the existing holes does not fit, then it is not a problem to drill new ones using a conventional drill.

Rack profile for walls

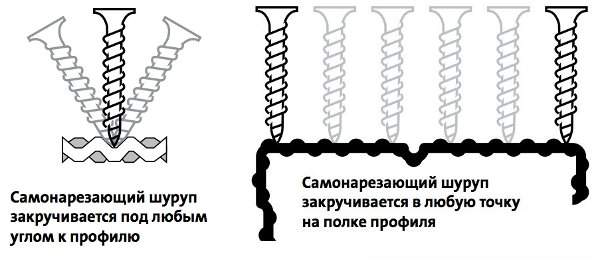

The rack metal profile, designated PP or CD, forms a plane to which drywall will be attached. It is easy to distinguish this variety from guides: its side walls are bent inward, forming the letter “C” in cross section. This makes it more rigid, it is easy to attach suspensions to it. The element has longitudinal stiffening ribs, which have an additional function: it is convenient to center self-tapping screws in them.

In order not to get confused, we will give all the names of the CD profiles. They are called ceiling profiles, rack-mount, planar, racks.

Product dimensions:

- Various lengths: from 2,500 mm to 6,000 mm. Thanks to this, it is easy to choose the required size, since it is undesirable to splice such load-bearing elements.

- Shelf height is standard and is 50 mm.

- Width - 50, 65, 75 and 100 mm.

The rack profile is inserted into the guide, so it must match it in width.

Profile for ceiling frame

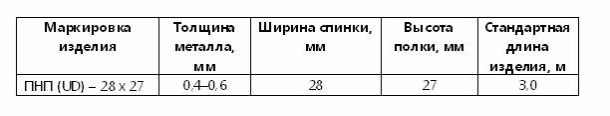

To align ceilings or create multi-level structures on them, use the same UD and CD profiles. The only difference in the choice of products is their size. For the ceiling, elements with the following parameters are usually taken:

- Guide rails 3,000 mm long, 28 mm wide and with a side shelf height of 27 mm.

- Ceiling load-bearing metal profiles of the same length, with the same shelf height and 60 mm wide. The presence of additional stiffeners along the length allows you to create structures on the ceiling that can withstand heavy loads.

Profiles for forming partitions, niches and arches

The active use in the repair of structures erected from drywall led to the release of a wide range of parts for carcass formation. The buyer can choose those that are required by him for a particular case.

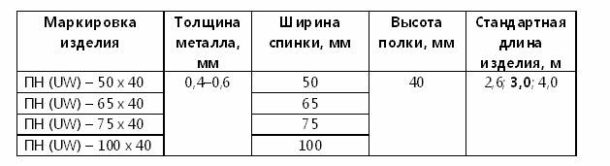

Guide partition profile

Guide metal profiles UW (PN) have different widths. This is due to the fact that the thickness of the erected partition can be different. Therefore, in the assortment of stores you can find UW profiles with a width of 50, 65, 75, 100 mm.

The length of such products is from 2 to 4.5 meters. The height of the side shelves is 40 mm.

Rack partition profile

Rack profiles for partitions CW (PS) have an interesting feature: you can mount drywall on them on both sides. Often they provide notches for laying communications. In terms of dimensions, they are selected for the guides used.

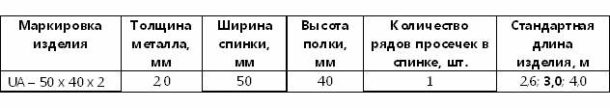

Reinforced metal profile

To strengthen the doorways, a reinforced version of the profile (UA) is used.

It is mounted in them as racks and has the following dimensions:

- Length - 3,000, 4,000 and 6,000 mm.

- The height of the side shelves is standard - 40 mm.

- Backrest width - 50, 75 and 100 mm.

The increased strength is provided by the thickness of the metal, reaching 2 mm. The back of the part is provided with perforations and holes to facilitate installation.

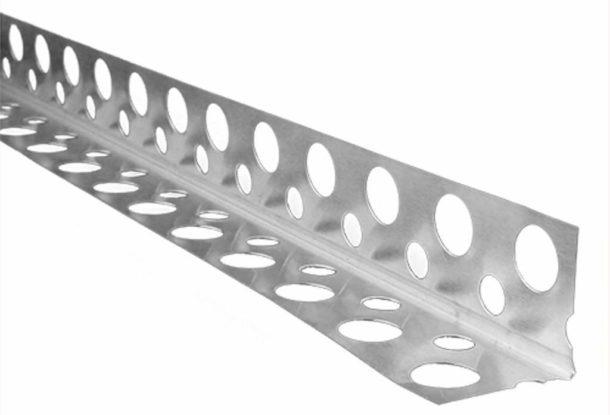

Angle profile

The corner profile is designed to protect against accidental damage to the corners of plasterboard structures. As a rule, it is attached to putty, therefore it has a perforation through which excess mortar is squeezed out. Produced in strips 3 meters long. The width of the sides of the corner is 25 or 31 mm.

Care must be taken when transporting these parts as they are easily deformed.

arched profile

The arched profile differs from other types by the presence of cuts on the side shelves, which allows you to bend it, giving the desired radius of curvature.

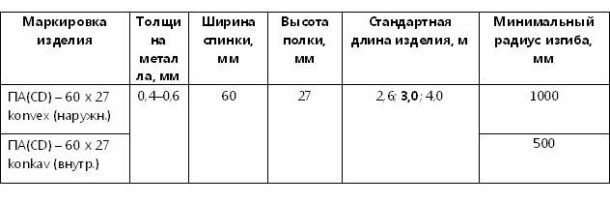

Arched elements can be convex or concave. Their characteristics are slightly different:

- Convex are available in lengths up to 6 meters and can provide a minimum bending radius of 1000 mm.

- Concave - 3 meters long, minimum radius - 500 mm.

Often, when forming curved surfaces, craftsmen do without using this type, replacing it with a guide. In its side shelves, cutouts in the form of petals are made at a certain interval, as in the photo. The smaller the bend radius, the more often cuts are made.

How to choose the right profile

A reliable frame is the key to the strength of the design of their drywall. Therefore, you should not save on the materials necessary for its manufacture. It is better to choose profiles of a well-known company, even if the price of products is higher. But in this case, you do not have to worry about the quality of the metal profile.

ibuilder.decorexpro.com/en/ recommends: Choose items that are at least 0.5mm thick. Ideally - from 0.55 mm. Profile rigidity is our everything!

Qualities that a profile for GKL must correspond to:

- strength and rigidity - are provided by the thickness and proper processing of the material during manufacture;

- reliability - it is determined by the quality of steel;

- lightness - too thick material has a lot of weight, and it is inconvenient to work with it.

When buying profiles, you should pay attention to the conditions of their storage. Despite the corrosion resistance of galvanized metal, products are supposed to be stored under a canopy. Profiles should be free of scratches and burrs. It is good if the parts are delivered in packaged form.

Best of all, products from the world leaders Knauf and Giprok have proven themselves.

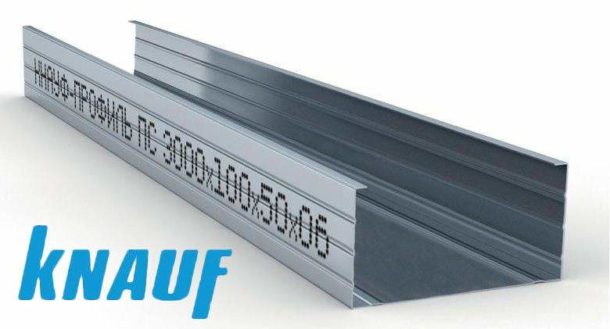

Profile from Knauf

Features of Knauf products:

- galvanized steel 0.6 mm thick;

- special geometry to create tight joints without gaps and deformation of the shelves of elements;

- stiffeners for frame strength and easy orientation during assembly;

- holes with a diameter of 33 mm for dowels, installation of communications.

The disadvantage of Knauf metal profiles is only one - the high price.

Gyproc-Ultra

Advantages of the Gyproc-Ultra profile:

- cold hardening of steel using UltraSteel® technology;

- harpoon effect: the self-tapping screw is easily screwed in, but difficult to get;

- holes closed with a tongue, which, when bent, prevents the part from bending when screws are screwed in;

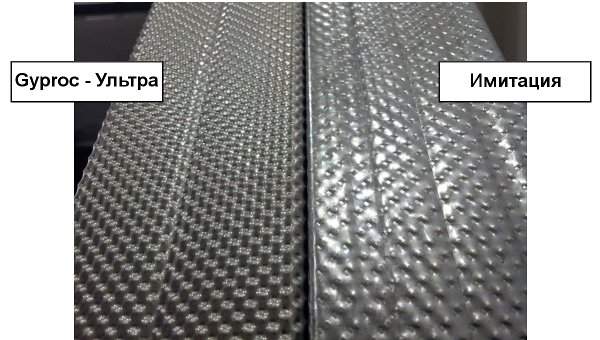

- corrugated surface with symmetrical recesses, allowing self-tapping screws to easily enter the metal and not slip off;

- connection of elements by the thorn-groove method.

Note! There are many fakes and imitations of the Giprok-Ultra profile on the market. When buying, carefully consider the detail: the corrugation of the original goes to its full thickness, the recesses are clear and symmetrical.

In terms of price / quality ratio, Giprok outperforms Knauf.

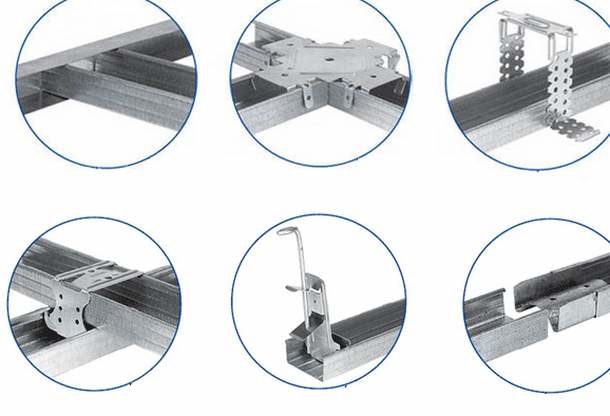

Fasteners for mounting the frame

Assembling the frame will not work without a variety of fasteners. Depending on the type of structure, the following elements can be used:

- Direct hangers – for mounting support profiles on a ceiling slab or wall. On the surface they are fixed with dowels. The carriers are fixed in suspensions with self-tapping screws. There are a number of holes in the side wings of this fastener for adjustment. After fixing, the protruding parts are simply bent at an angle of 90˚ so as not to interfere with the installation of drywall.

- Anchor hangers - for mounting the ceiling frame. They have a rod, by adjusting the length of which, you can set the required distance between the frame and the ceiling.

- Extensions - for connecting profiles. Such a need arises quite often, and the use of an extension cord allows you to get a stronger and more rigid connection.

- Connectors - for fastening profiles perpendicular to each other. There are one and two levels. A single-level connector is often called a crab because of its shape.

- Small self-tapping screws for metal - for fastening metal frame parts together. However, professionals advise using for these purposes cutter. It provides a smooth surface at the mating point, while the heads of the self-tapping screws can prevent the drywall from fitting snugly to the frame.

Dear readers! Please write in the comments what brands of metal profile you use. If you used a Chinese profile to assemble the frame, tell us what came of it.