When redevelopment in an apartment or a private house, there is a need to create additional partitions that divide the room into separate zones or rooms as conceived by the designer. Previously, such structures were built of brick or wood, but recently drywall has been preferred. This affordable material has a lot of advantages, and even a novice master with minimal building skills can make a drywall partition.

Advantages of using drywall when creating partitions

What are the advantages of using GKL when building additional walls in a room?

- The construction from it is obtained much easier than from brick or concrete, which minimizes the load on the floors. This is true enough for rooms in apartment buildings.

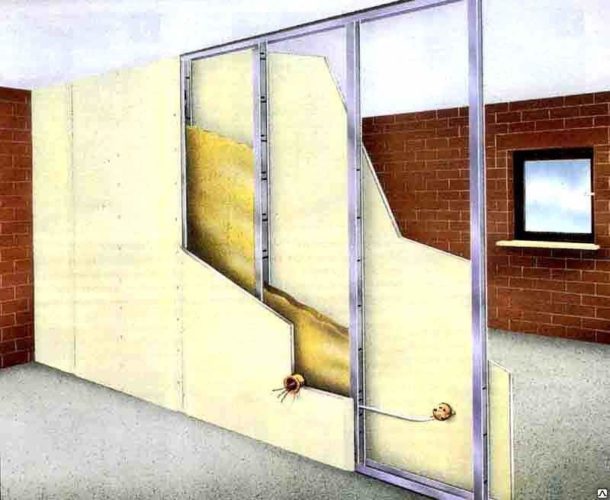

- In the cavities of a plasterboard partition, you can additionally place a layer of sound insulation or insulation, as well as stretch electrical wiring. Unlike stone walls, this can be done without the dusty and time-consuming chasing operation.

Drywall itself has good soundproofing properties, so even without additional materials, such a wall will prevent the spread of sound.

- GKL is environmentally friendly and fireproof.

- The resulting plane after minimal processing is ready for further finishing. The sheets form a smooth surface that can be painted, wallpapered, covered with decorative plaster or even ceramic tiles.

- Easy assembly. Almost everyone can install a drywall partition with their own hands, following a simple step-by-step instruction. It does not require specialized skills or expensive professional tools.

- Drywall allows you to easily realize various design ideas: you can arrange a partition in the form of an arch, make a niche for a TV or other household appliances, build built-in shelves and much more.

Of course, there are also disadvantages. The main one is the relative fragility of drywall: it is much easier to damage such an interior partition than, for example, a brick one. In addition, even moisture-resistant GKL does not tolerate long-term exposure to excessive humidity.

Before assembling a drywall structure, you will have to decide on the location of all the interior details on the future wall: their attachment points must be strengthened even at the frame assembly stage.

Necessary materials

First of all, you need the drywall itself. The partition, of course, is not a load-bearing wall, but must have a certain strength. Therefore, sheets are taken with a thickness of at least 12.5 mm. Moisture-resistant and refractory varieties of this material are used only when necessary.

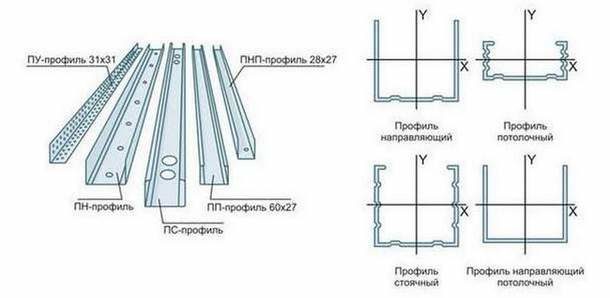

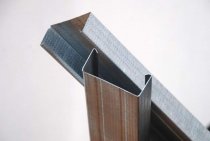

A galvanized metal profile is ideal for forming the frame. For most partitions, two types of it will be required:

- rack;

- guide.

The guides have a standard length of 3 m. The size of the required rack profiles is selected based on the height of the room where the partition is being built.

Horizontal lintels, which give rigidity to the structure and form doorways, are also made of a rack-mount profile. Therefore, the exact amount of this material is calculated only after drawing up a detailed frame diagram, taking into account the mandatory stock.

In addition to the GKL and the profile, you will need for work:

- Dowel-nails for attaching guides to the walls, ceiling and floor of the room. In a wooden room, they are replaced by wood screws.

- Sealing tape to improve sound insulation. It is glued on the back side of the metal profiles, prevents the transmission of sound vibrations from the main walls to the frame.

- Beam to strengthen the doorway.In size, it should fit tightly inside the rack profile - this will facilitate its installation.

Professionals advise fastening profiles to each other using cutter. But this tool is still not widely used, therefore, small self-tapping screws for metal, popularly called "fleas" or "bugs", are more often used.

The resulting drywall surface is prepared for further finishing, so it will come in handy:

- Reinforcing tape (serpyanka) and putty for processing and strengthening the seams between sheets of drywall.

- Primer designed for GKL.

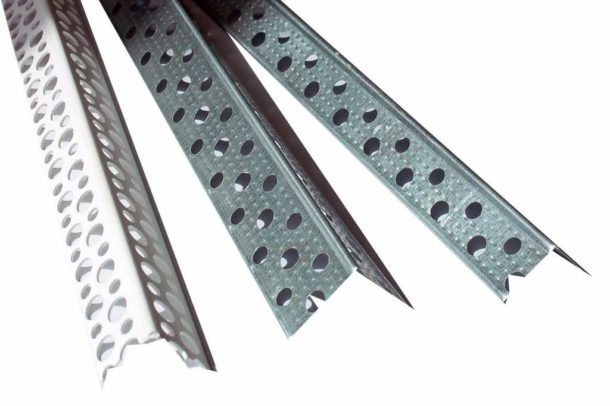

- Corners with perforation for processing corners.

If it is planned to fill the voids in the partition with insulation or sound insulation, then they are also purchased.

Tools

The list of required tools includes:

- Perforator with the right drill. The most popular dowels are 6 mm in diameter.

- Metal scissors.

- Screwdriver with a set of bits.

Recommended to purchase drywall bit with limiter: it will not allow self-tapping screws to push through the surface of the GKL. It costs a little, but makes the job much easier.

- Hacksaw for cutting drywall, painting knife.

- Crown set. Allows you to neatly arrange holes for sockets and switches.

- Brushes and roller for applying primer.

- Spatulas.

- Marking tool: tape measure, plumb line and level.

Frame diagram

It is impossible to properly build a partition without creating a drawing. It will be required already at the stage of material procurement. Yes, and it is impossible to calculate in the mind all the subtleties of placing profiles and fixing GKL. The drawing will help to use the material more rationally and avoid its unwanted losses.

The dimensions of the future partition are determined as follows:

- The required size of the separated room or section of the room is deposited on each wall. This is done twice: at the level of the floor and ceiling.

- The resulting lines are connected vertically, their location is controlled by a plumb line.

Such an algorithm is needed due to the fact that in apartments, floors are rarely even and located at right angles.

- The verticals on the walls are connected by lines on the ceiling and the floor surface, resulting in the contour of the future wall.

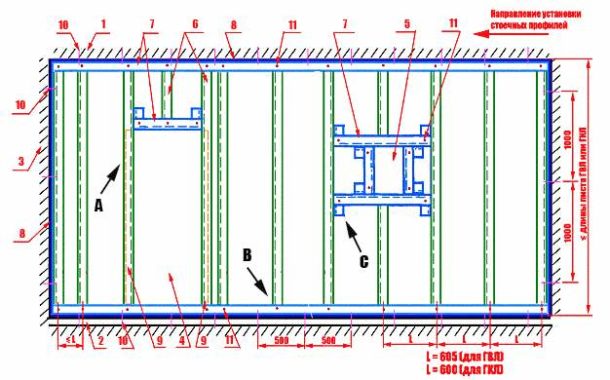

The drawing is transferred to paper, the location of the rack profiles and partitions is outlined, as well as the doorway. In this case, the following rules are observed:

- Vertical racks are located in increments of 400 or 600 mm. This will allow you not to resort to unnecessary cutting of drywall sheets: they will be joined on the profiles.

To stiffen the structure, the sheets on both sides must be connected on different racks. For example, on the front - on odd profiles, on the back - on even ones.

- The space above the door is further enhanced by at least a pair of rails.

- At the same stage, the attachment points for all additional accessories, such as a TV, are determined. These areas are also enhanced.

- The number of required horizontal jumpers is calculated. GCRs are joined on them if the partition is longer than their length. But even when the sheet completely covers the opening in height, it is recommended to fix a pair of horizontal profiles to stiffen it.

And one more important point. If a sliding door is installed in the partition, the doors of which, when opened, will enter the plasterboard wall, the profiles should be arranged in 2 rows, as in the photo.

Note! In such a design, in the direction of movement of the door leaves, jumpers, wires and any other communications and obstacles should not be located.

The next photo is a simpler solution. A standard wall is made with an opening, and the sliding door is located outside, on one side.

The frame for the partition with niches shown in the next photo has a more complex design.Independent production of niches is described in detail in this article.

According to the drawing, the required amount of material is calculated. After purchasing it, you can proceed to the installation of the frame.

Frame assembly

At the first stage, we construct a frame from guide profiles:

- Using scissors for metal, we adjust the elements in length.

- Usually they already have holes placed with the desired pitch. If they are not, then it is necessary to drill holes for fasteners every 50–60 mm.

- We glue a sealing damper tape on the back side of the profile.

- We apply the profiles in place and mark the holes for the dowels. It is necessary to ensure that all guides are on the same side of the markup line.

- We form holes with a perforator and drive in plastic dowels. Then we fasten the profiles, hammering the dowel-nails with gentle hammer blows.

In the case of wooden walls and ceilings, the procedure is simplified: the dowel-nails are replaced with wood screws with a wide hat.

Mounting racks and horizontal jumpers is easy:

- We cut the vertical elements so that they are 8-10 mm less than the height of the room.

- After installation in the guides, we fasten them with small screws or a cutter.

The use of a cutter has an important advantage: the junction is absolutely smooth. The caps of the self-tapping screws will prevent the plasterboard sheets from fitting snugly to the frame.

- The verticality of the installation of each guide is controlled using a level.

- We cut horizontal jumpers into elements whose length exceeds the distance between the racks by 100–200 mm. At the ends, we remove the side walls, forming a flat "tongue". Then we fix them with screws to the racks.

A more reliable, but also more labor-intensive method of forming horizontal jumpers: having cut through the side walls, we bend the excess on the profile at a right angle. After that, we put the resulting “ears” on the vertical racks from above and fix it. This is usually done when forming a doorway.

- The opening under the door is definitely reinforced. This can be done by twisting two profiles together or by inserting a wooden beam inside the metal elements.

The process of creating jumpers and assembling the frame using a cutter is presented in more detail in the following video.

Fastening and processing drywall

GKL fixing is carried out as standard:

- According to the markup, we cut the necessary fragments using a hacksaw or a painting knife. With a knife, we cut the cardboard along the marking line on one side of the sheet. We carefully break the drywall and turn it over to cut through the cardboard from the back.

- At the junction points on the fragments, there must be chamfers. It is recommended to form them before fastening with an edge planer or a painting knife.

- We fix drywall to the frame with metal screws. A special bit under the GKL for a screwdriver will greatly facilitate this process. The step between the fasteners is 10–15 cm.

On the joined sheets, the attachment points are located apart.

- In the drywall surface, if necessary, we drill holes for sockets and switches.

- We glue the joints with reinforcing tape and close up with putty. After it dries, the surface is rubbed and primed.

At the end of all operations, a solid and even partition is obtained, ready for further finishing.