The construction market is dominated by PVC windows. Why are they so good? What plastic windows are the best? We will try to answer these and many other questions in detail.

Design

Metal-plastic (plastic) windows, despite the apparent external simplicity and unpretentiousness, consist of many details, some of which are not visible during a superficial examination. Each component has its own purpose, they are all products of innovative production.

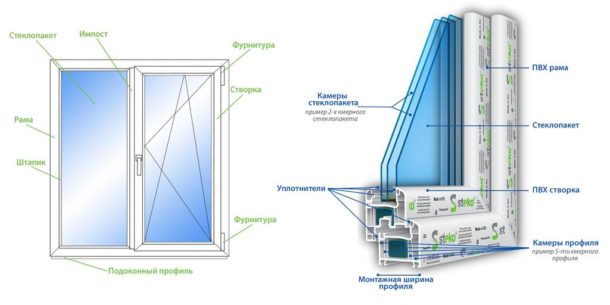

The main components of the design:

- plastic frame (profile);

- reinforcing elements for reinforcement;

- subframe (bearing profile on which the window is mounted);

- double glazing;

- fastening strips - glazing beads.

The components also include:

- rubber seals;

- fittings (hinges, handle, latch, other);

- slopes;

- low tides;

- windowsill.

In summer, for ventilation of the premises, the windows are open for a long time. And in order to prevent insects from entering the house, they are equipped with removable mosquito nets.

PVC window systems are reliable, convenient, and quite inexpensive. Their advantages also include a high level of maintainability. If any component of the window fails, it can be easily ordered and replaced.

What can be plastic for windows: quality and properties

For the production of the frame, two types of PVC are used: matte and glossy.

Samples of the first type are cheaper, but their surface is slightly rough, which can be felt by hand. Such frames absorb dirt like sponges, gradually turning from white to gray with stains. It is not possible to clean them qualitatively with standard detergents.

Samples of the second type are more expensive, they are also easy to identify by touch - the surface is smooth, as if polished. Such frames repel dirt, they are easy to clean with conventional tools and products. In order not to run into low-quality goods, it is better to buy metal-plastic windows of well-known brands.

Polyvinyl chloride, in addition to many advantages, also has disadvantages that companies that produce window blocks have to take into account.

Here are the main ones:

- Low strength. This is compensated by reinforcing steel inserts. And also the design is supplied with internal partitions of a certain thickness, which play the role of additional stiffeners.

- Low resistance to temperature changes, low resistance to ultraviolet rays. This is eliminated by adding stabilizing and modifying particles to the composition of polyvinyl chloride. In high-quality PVC, they are not hazardous to health.

If a metal-plastic window is a source of an unpleasant pungent odor, then you should refrain from buying it. Most likely, an unscrupulous company saved on quality additives by replacing them with cadmium or lead.

- Significant level of linear expansion. The indicator is one to two millimeters per 1000 millimeters of profile length. This feature of the material is leveled by reinforcement, accurate calculation of fasteners, and compensating gaps are provided in the design.

What is a PVC profile made of?

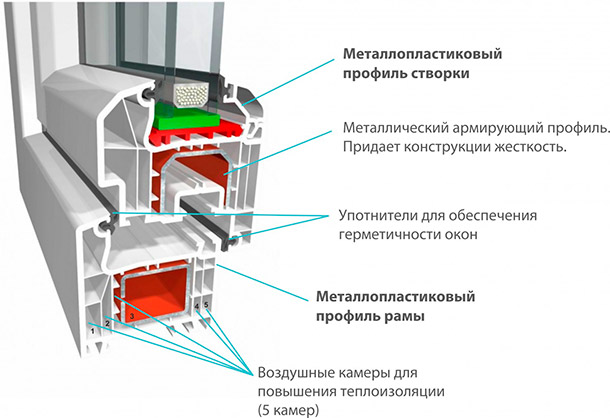

The plastic frame is not uniform. In addition to the plastic base, it includes profile reinforcing elements, sealing gaskets.

Read more about how to choose a PVC profile in our separate article.

The window plastic base is made of polyvinyl chloride (PVC), two-thirds of this material consists of a variety of chlorine that is not hazardous to health. This type of plastic does not emit a characteristic odor, does not collapse under the influence of low temperatures in winter (limit - 25 degrees), retains a given shape in extremely hot weather in summer (up to + 65 degrees).

PVC structures have good waterproofing properties, a high level of moisture resistance.PVC window systems are suitable not only for the living room or bedroom, but also for rooms with high humidity levels (kitchen, bathroom).

Rubber gaskets ensure the tightness of the window system, they seal the contours of the frame, double-glazed windows. This type of seal is specially designed: if it becomes unusable, then it will not work to change it without a special skill, you will have to call a specialist. The sealing of the sashes and seats of double-glazed windows is standard, if necessary, it can be easily replaced.

In order for the double-glazed windows to sit firmly in the seats, plastic fastening strips - glazing beads are used.

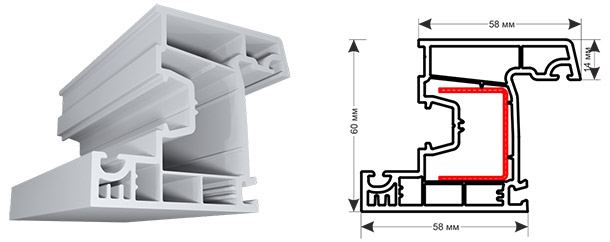

Classes and mounting width of the profile according to GOST

Historically, the installation width (the distance between two outer planes) of wooden window systems in multi-storey residential buildings in the countries of the former USSR ranges from 58 to 60 millimeters. Such dimensions, according to calculations, correspond to the temperature specifics of the climate of Eastern Europe. Similar mounting width for most plastic windows, which replaced outdated wooden ones. The specified overall indicator is sufficient for the installation of a three-chamber system, popular in our market.

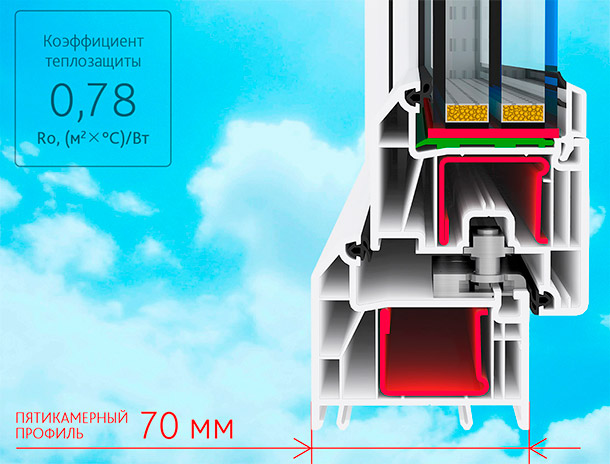

If the apartment is located at the top of a high-rise building or the local climate is characterized by strong winds and low temperatures, then a four- or five-chamber sample should be installed. This window corresponds to a mounting width of 70 millimeters.

There is no direct relationship between the frame width and the number of chambers. For example, there are models with three chambers, while the installation width is 90 millimeters. The thermal insulation parameters in such a window system are much better than those of multi-chamber counterparts.

This is explained by the fact that the thermal insulation properties are improved not by the number of chambers, but by their dimensions and the volume of air mass contained in them.

The main characteristic of a PVC window profile is the thickness of the front walls and lintels of the inner part. Dimensions, types and other parameters of all components of window systems are regulated by the technical conditions of regulations. In the European Union, these are EN 12608 SR standards. Companies in the territory of the former USSR are guided by the norms:

- GOST 30673-99 PVC profiles for window and door blocks.

- GOST 23166-99 Window blocks.

- GOST 30674-99. Window blocks made of PVC profiles.

The technical conditions of the regulations are almost identical; according to these documents, the profile is classified into three groups:

- A-class samples. The smallest value of the thickness of the front wall is 2.8 millimeters, the same indicator of the partition of the inner part is 2.5.

- B-class samples. The minimum thickness of the front wall is 2.5 mm, the same indicator of the partition of the inner part is 2.

- C-class samples. This group includes a profile whose parameters do not correspond to the first two classes, it is called an object profile. Usually, the wall thicknesses of the object samples are less than those of the A and B-class models.

The scope of A-class metal-plastic windows is heated residential premises; B-class - installation in unheated and heated buildings is possible; C-class - only in buildings without heating.

B-class windows are less durable compared to A-class counterparts, their service life is shorter. C-class samples most often represent a monolithic system.

Number of air chambers

In metal-plastic windows, air chambers have a dual purpose.

- Firstly, they prevent heat exchange between the air masses indoors and outdoors (thermal insulation function).

- Secondly, they reinforce the design of the window frame, contributing to the tightness, strength and long life of the window.

The temperature indicators in the rooms and in the environment during the cold season vary significantly, this contributes to the formation of water droplets in the cavities of the window system.To remove moisture to the outside, special holes are provided (on the "street" surface of the profile). They do not affect the thermal insulation performance of the system. To prevent the channels from being noticeable, they are covered with special plugs.

On low-quality cheap PVC windows, such technological holes are not always available (they are made at the factory, you should check their presence).

The most popular are three- and five-chamber frames. If the apartment is located in the lower part of a multi-storey building, the window openings face south or west, there is no highway or any noisy objects under the windows, then it is enough to install a three-chamber sample (profile thickness 58 millimeters). The location of the apartment on a high floor, openings facing north or east, the highway near the house - this is the reason for installing a five-chamber window system (profile thickness 70 millimeters).

All these recommendations apply to the European climate, but if the weather conditions are more severe, then the installation of five-chamber windows becomes uncontested.

A few years ago, companies began to make samples, in which chambers are not air mass, but polystyrene foam. With such a filler, a smaller number of chambers in the profile contributes to a higher level of thermal insulation, which is indexed by a special coefficient.

A five-chamber sample corresponds to a heat resistance coefficient of 0.72 units, a three-chamber sample, 0.64 units.

Reinforcement

So that the plastic base of the windows does not deform during operation, it is reinforced, that is, metal elements are inserted into the cavities along the perimeter of the frame. They are made from a steel strip with a thickness of one and a half to two millimeters. The blanks are usually coated with a layer of white zinc, which protects them from corrosion.

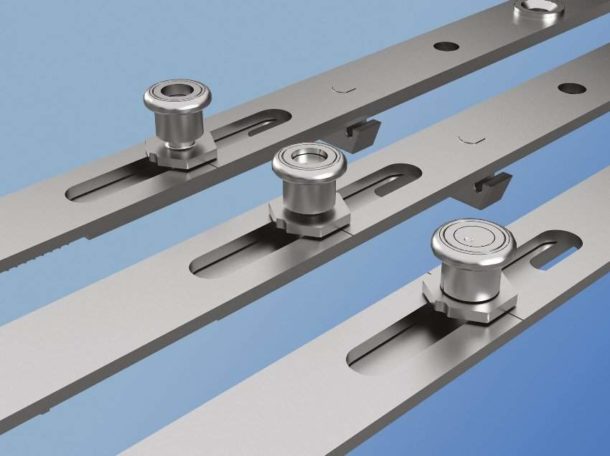

Reinforcing profile it happens with a section in the form of the letter "P" or in the form of a square. The second type can withstand significant loads, so window systems with large dimensions are reinforced only with square-section blanks.

If the frame length is less than 80 centimeters, then, according to the regulations, reinforcement is not required.

Profile Options

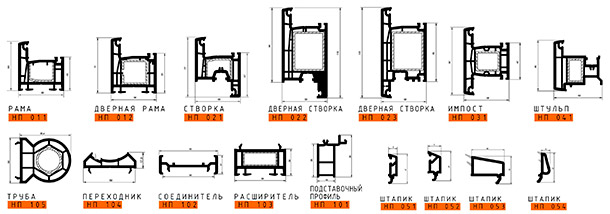

The window metal-plastic block is a complex system consisting of many components. The PVC profile is used not only for the production of a frame, but also for other purposes, for example: when articulating window systems at an angle, when fitting, and so on.

The main types of such a profile:

- Connective. This type is used for glazing complex structures, the components of which are located in different planes at an angle to each other. Typically, such work is carried out in winter gardens, greenhouses, loggias, non-traditional balconies.

- Expansion (additional). The dimensions of the seat are not always standard and correspond to the mounting dimensions of the window unit. In such circumstances, an additional profile is used to fit. Its standard width is from 20 to 100 millimeters.

- Installation (stand). This PVC element contributes to the reliable installation of sills and window sills, protects the structure from damage during storage and transportation. Standard dimensions (in millimeters): depth - from 20 to 40, height - from 20 to 30, length - 6000. Depending on the climate, a profile with two or three chambers is chosen.

- Starting. It is used in the installation of slopes, their articulation with each other. It is divided according to the shape of the section, which resembles the letters of the English alphabet (F, I, L, double L). This type of profile is connected with glue or hardware.

- Water slat. PVC part that prevents rainwater from penetrating the window when the sash is tilted. Many companies neglect this useful component, although not all models can be mounted with it. A water-draining bar is not placed on colored window blocks due to the risk of deformation at high temperatures.

colored windows

Most choose white PVC window systems, but there is a demand for multi-colored PVC profile, although such windows are noticeably more expensive.Color profile properties are different from white.

For example: color is heated more strongly in summer. Therefore, in order to avoid deformations, even small-sized parts should be reinforced.

In the production of colored PVC components, acrylic dyes, lamination, spraying, etc. are used. In elite models, multi-colored curly plates are used. The surface of the window itself can be not only flat, but also rounded, corrugated, etc.

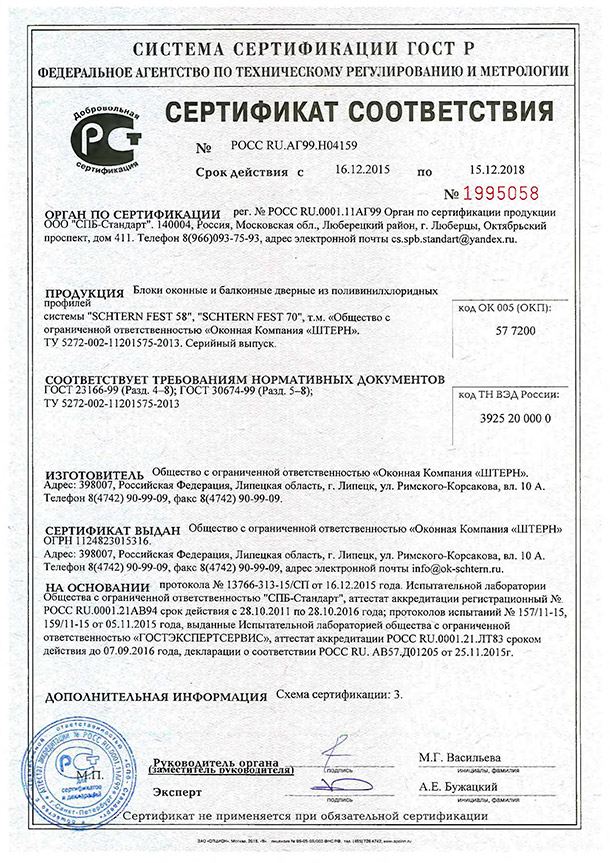

How to choose a profile, quality certificates

The market for metal-plastic window systems is full of products from different companies. When buying a window, you always want to pay less, but at the same time the goods should be of high quality. However, a good window of a famous brand cannot be cheap, and the high price is offset by its long trouble-free operation. A window block of dubious origin will quickly break down, you will have to spend money again to buy a new, higher-quality sample.

What to look for when choosing? In order not to run into a fake and be one hundred percent sure of the quality, you should purchase goods only from a well-known world brand with an impeccable reputation and a long history of work in the market. The profile should be pleasing to the eye, smooth to the touch, free of defects or noticeable unpleasant odors. The dimensions of the window system must correspond to the dimensions of the opening, it is necessary that the indicators of thermal and sound insulation of the profile correspond to the specifics of the location of the apartment, the climate.

Products must be accompanied by an international quality certificate ISO 9000 and ISO 9001.

- Strength must matchDIN 53453 and ISO 179-61.

- Durability of plastic DIN 53387.

- Profile hardness —DIN 53456.

- High temperature resistance - DIN 53460 and ISO 306-68.

Most companies produce metal-plastic windows not only for apartments or houses, but also for technical non-residential premises. Such a profile is called an object profile, upon a cursory examination it is almost indistinguishable from a normal one, there is no marking or there is an inscription “object”.

However, physical and mechanical characteristics of object samples are much worse, low-grade PVC. In order not to become a victim of fraud, you can buy windows only in large well-known retail chains.

Double-glazed windows: design, planting depth, decorative elements

double glazing - one of the main components of the window unit, which makes up about 80% of its area. He is responsible for the light transmission of the window, its thermal insulation capabilities. The quality of mounting a glass block in a profile depends on the depth of the seat. In good models, the distance between the frontal plane of the profile section and the outer glass should not be less than 15 millimeters. The optimal value of this indicator with a window system seat depth of 50–70 millimeters is 18 millimeters. Insufficient planting depth of the glass block will cause the windows to fog up or freeze.

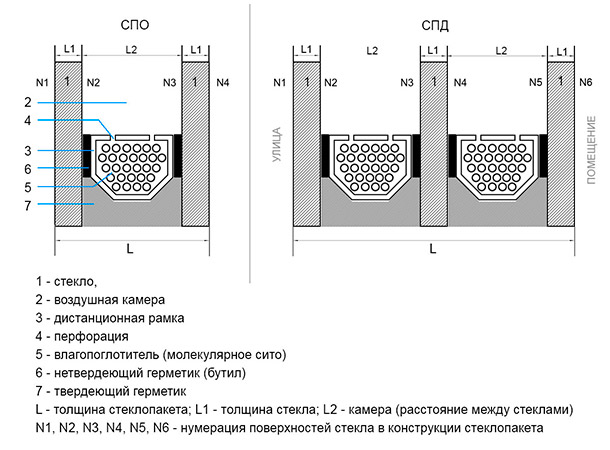

The composition of the double-glazed window includes sheet glass and chambers filled with an air-gas mixture. To protect the unit from the effects of the external environment, distance frames are used. From the outside, viscous polymer-based compositions (sealants) are applied to them, which are applied in several layers along its perimeter. These polymer compositions also prevent the gas mixture in the cavity of the glass block from leaking. To prevent the formation of moisture in the inner part of the double-glazed window, a layer of granules absorbing it is placed in the frame.

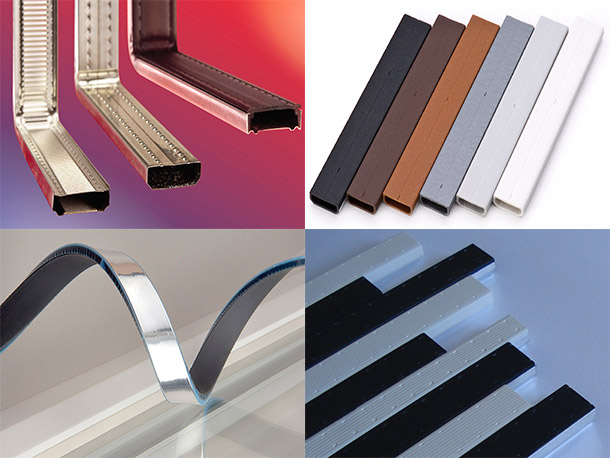

Distance frames are of several types:

- aluminum;

- steel;

- plastic.

The latter, in turn, are of different types:

- thermoplastic frames (TPS);

- swing strip;

- TGI;

- super spacer.

Aluminum is considered the coldest, then steel, and the warmest are plastic spacers. For example, the Super Spacer product retains 80% more heat than its aluminum counterpart.

To improve the functionality of the double-glazed window, the air chambers of some models are equipped with decorative fixtures. Usually these are screeds (weaves), roller-type curtains, blinds.

In this case, the smallest allowable thickness of the chamber should be 20 millimeters. Components are not serviceable due to the nature of the glass block design. They are controlled either manually by means of handles, or by an electric (magnetic) drive.

Types of glasses used

An ordinary buyer without special skill will not be able to determine the type of glass in the window system that he is going to buy. Visually, they are very similar, so it remains to be hoped for the integrity of the manufacturing company, which declares one or another type of material in the accompanying documents.

We list their main types:

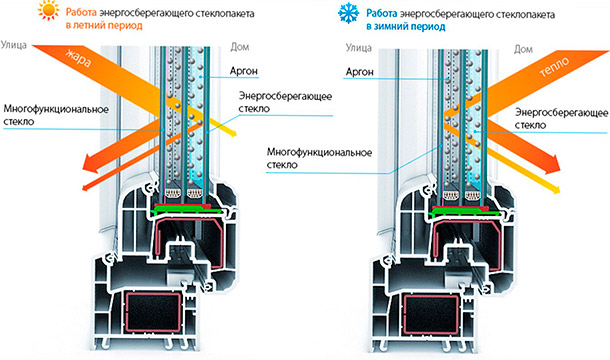

- Energy efficient. A thin layer of silver and titanium oxides is sprayed onto the glass surface, the particles of which can only be seen under a microscope. Silver plating reflects the flow of thermal energy. There are K and I models. It is the latter that are most often used, since their production is simpler and they have more positive properties. If energy-efficient I-glass is installed on the inside (facing into the room) of the window block, then it reflects heat from the room inside, and in the cold season the apartment will be noticeably warmer. If it is installed on the outside (facing the street) - the heat from the sun's rays does not penetrate inside, and in hot weather the room will be cooler.

The ideal solution: to assemble a two-chamber thermal bag from two i-glasses and one regular one in the middle.

You can check such glass by bringing a flame from a candle or lighter. The reflection will double, the second should be dimmer than the first.

- Multifunctional. During production, metal molecules are applied to their surface crosswise and in several layers. This allows infrared radiation to be reflected both outside and inside. Therefore, in winter it will be 80% warmer than with ordinary glass, and in summer there will be no greenhouse effect, and you can save energy on cooling the room. The disadvantage is the lower light transmission (by 20%).

- Sun protection. When the windows of the apartment fall under the direct rays of the sun in the summer, the air in the room heats up quickly. You can prevent this by installing tinted double-glazed windows. A thin film is glued onto the surface of the glass, which creates the claimed effect by absorbing sunlight.

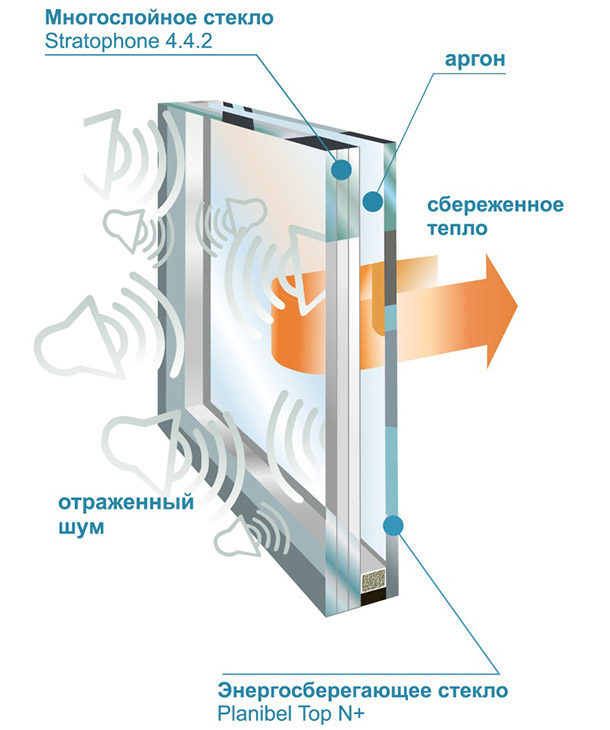

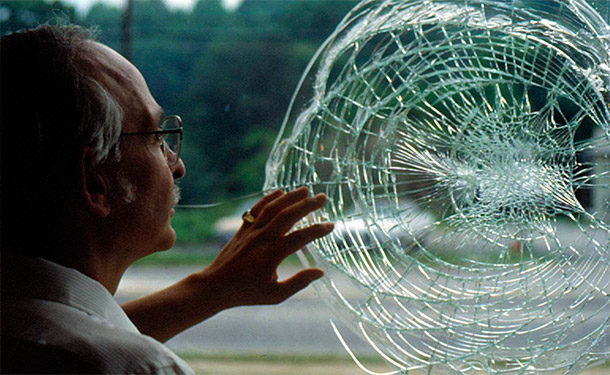

- Laminated (armored). Such models are made according to the technology for manufacturing windshields for a car: the sample consists of several thin layers glued together. This manufacturing method provides high strength glass blocks that can withstand significant mechanical shocks. In the event of destruction, the canvas does not break up into many pointed parts, but is covered with a network of cracks. In addition, these models provide a high level of sound insulation.

- Hardened (stalinite). As a result of a special heat treatment, stalinite receives a strength margin six to seven times greater than that of untreated glass. Able to withstand significant mechanical shocks, no sharp parts are formed during destruction.

- Reinforced. When reinforcing, a metal or transparent plastic mesh is used. Such glass has a high level of safety, strength. Improve anti-vandal and anti-burglary properties of windows.

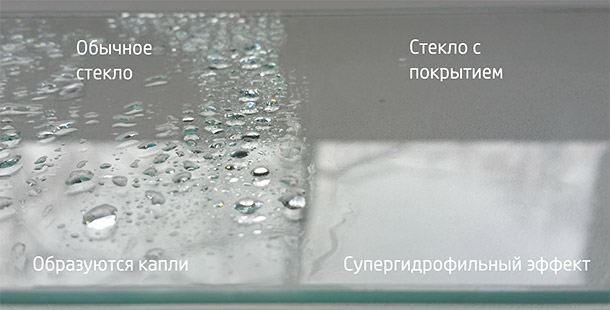

- Self-cleaning. A layer of a special substance is sprayed onto the outer surface of the glass, which prevents dirt from accumulating. At the same time, the window unit always maintains a high level of light transmission.

Almost all types are made on the basis of float glasses, which are cast sheets. They are cast at a temperature of 1000 degrees, have an almost perfectly flat surface.

Dimensions of double-glazed windows

In massively demanded window blocks, sheet glass of various types is used, the thickness of which is from 3 to 6 millimeters. It is irrational to use thicker ones in residential buildings. Sheets with a thickness of 8, 10, 12 millimeters are cast on special orders, used in buildings with non-traditional architectural solutions or at special-purpose facilities. About 90% of all double-glazed windows produced are 24, 26, 32 millimeters thick. With such standardization, it is easy to find a replacement for a broken block.

The physical properties of glass impose some restrictions on the dimensions and proportions of structures made of this material. The length of the side of the glass block should not be less than 300 millimeters, and the maximum possible proportions are five to one. For double-glazed windows with one chamber, where the glass thickness is 4 millimeters, the largest allowable area is 3 square meters. If the thickness is 5 millimeters, the allowable area is 4.2 square meters.

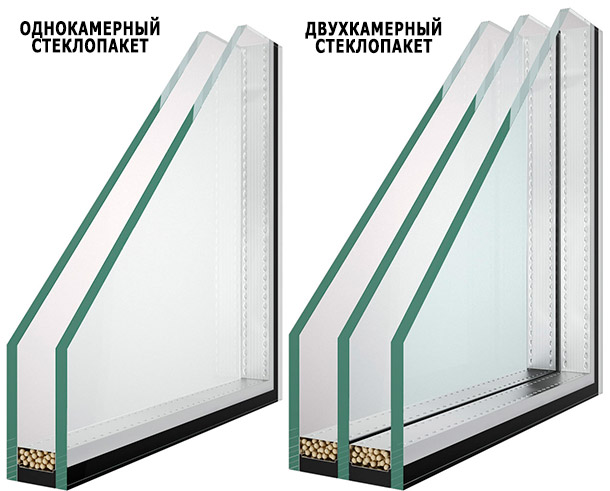

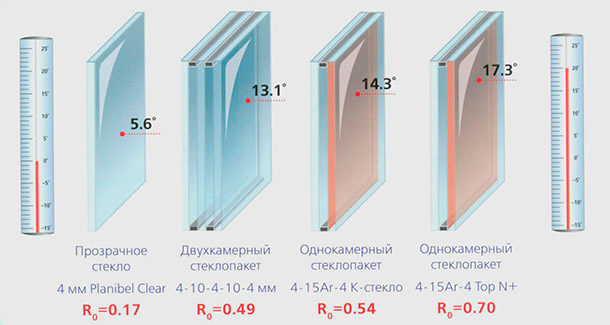

Depending on the location of the apartment, as well as local climatic conditions, the number of cameras in the glass block is selected. Almost always, the choice is between one or two chambers; such samples fully satisfy all the requirements for thermal insulation.

There are window systems with three or four chambers in a glass block, but they are too heavy (some up to 100 kilograms). Considerable weight complicates operation, quickly disables fittings. If, during the installation of single or double glazing, there remains a need for additional thermal or sound insulation, then there are alternative methods for these purposes.

Sealing of double-glazed windows

In order for the air chamber of the glass block of the window to retain high thermal insulation properties, and the glass to remain transparent, two-layer sealing is performed along its perimeter (edges). The first layer is a non-hardening butyl-based viscous composition that protects the chamber from contact with the external environment.

The sealant is not affected by thermal deformation, the remote perforated frame slides over the glass without damaging it. The second (upper) layer is a hardening viscous composition based on a polymer, due to its elastic properties, it maintains the tightness of a double-glazed window during thermal deformations.

Filling the air chambers

The main requirements for the window system, in addition to light transmission and the ability to ventilate the premises, are good thermal insulation and sound insulation. The level of these parameters largely depends on the contents of the chamber of the glass block. Initially, companies producing metal-plastic windows pumped dry air into the double-glazed window, the properties of which met the requirements for the level of thermal insulation and sound insulation. However, there are more efficient gas mixtures. We are talking about inert gases: krypton and argon. They are colorless, odorless, have low thermal conductivity, high ability to absorb sound waves.

If we compare the performance of the air mixture and the indicated inert gases, it turns out that the thermal conductivity of argon is lower by a third, and that of krypton by two thirds. Many profile brands are gradually refusing to pump air into the chambers of the glass block, using more efficient inert gases.

Purpose of the distance frame

In order not to reduce the level of all declared properties and characteristics, the design of a plastic window must maintain the constancy of geometric parameters. A significant role in fulfilling this condition is played by a gasket between sheets of glass, called a spacer. This item has a dual purpose:

- First: it guarantees the constancy of the thickness of the air chamber of the double-glazed window, that is, the gap between the glasses.

- Second, the spacer is filled with moisture-absorbing granules. For communication between the moisture-absorbing layer and the gas filling of the chamber, the surface of the frame is perforated.Such a system does not allow freezing or fogging of glasses.

In most cases, the width of the distance frame is from 10 to 16 millimeters, the maximum allowable dimensions are from 6 to 24 millimeters.

If the dimensions of the described gasket do not fit into the range of permitted ones, then a noticeable increase in the thermal conductivity of the double-glazed window and a violation of the original shape of the glass are possible.

Usually the gasket is made of metal: aluminum alloy, zinc coated steel or high alloy steel (stainless steel). Its thermal conductivity coefficient is lower than that of other metals used, however, stainless steel frames are more expensive and heavier.

The disadvantage of metal gaskets is their higher thermal conductivity compared to the same gas parameter in the glass block chamber. This difference somewhat reduces the effectiveness of the thermal insulation of the window block. Some companies, in order to level the disadvantage, make spacers from polymeric materials.

We recommend choosing plastic or composite products, they retain heat as much as possible.

Performance characteristics of double-glazed windows

Metal-plastic windows differ in many ways from archaic wooden counterparts, one of the main advantages is the versatility of the glass block, its complex design.

A double-glazed window is characterized by many parameters. The main ones are:

- thermal conductivity. 80% of the area of the window system falls on the glass block. Therefore, if you put a thin double-glazed window in a frame even with five or six cameras, then the overall energy efficiency of the window system will be very low. In a quality design, the resistance to heat transfer of all components should be equally high. To achieve the maximum values of this indicator, the glass block has three methods: increase the number of chambers, replace the air in them with a more efficient gas mixture, and also apply a special coating to the glass. Each of these methods has advantages and disadvantages; in a quality sample, a balance of different methods must be observed. For example: the more cameras, the higher the weight of the structure, which means that its operation becomes more complicated, the price increases significantly. A more effective and promising method for reducing the thermal conductivity of a window system is the injection of inert gases into the chamber, as well as a special glass coating (silver and titanium oxide). The combined use of such techniques increases the energy efficiency of the window up to 70%.

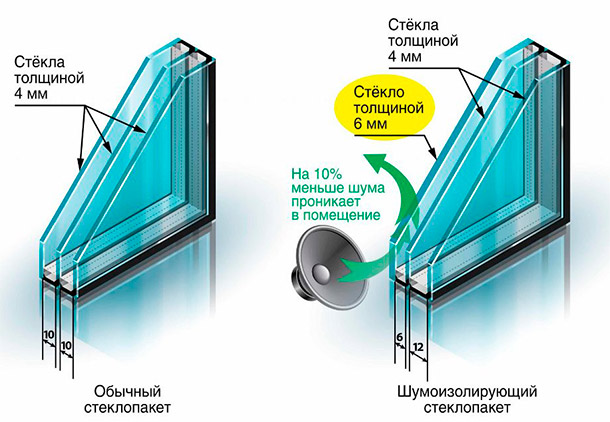

- Sound isolation. Three methods are commonly used to improve this parameter. First: injection of an inert gas (argon, krypton) into the chamber, which enhances sound insulation by 10%. Second: an increase in the dimensions of the distance frame, every two millimeters of the width of this gasket increases the sound insulation also by 10%. Third: installation of acoustic films on glass and installation of triplex on the outer contour of the double-glazed window.

- Safety. With all its advantages, glass has significant drawbacks - fragility, the appearance of fragments when it is destroyed. Three methods are also used to increase strength. First: the use of stalinite, its hardness is five to seven times higher than conventional samples. Heat treatment does not impair other characteristics of the material, such as light transmission, thermal conductivity, sound insulation level, etc. Second: the use of the triplex technique, when the glass consists of several glued thin sheets, alternating with a transparent polymer film. Upon destruction, such a sample does not break up into fragments, since they are held by the film. Third: reinforcement, a mesh of polymer or metal is used as a reinforcing layer.

- sun protection properties. To neutralize the undesirable effects of direct ultraviolet rays, you can use mirrored or tinted glass, which absorb and reflect about half of the sun's radiation.

Signs of poor quality glass

Only a specialist can reliably determine how high-quality a glass block of a window system is. However, there are a number of signs indicating the dubious quality of the product, which can be seen without special skills:

- Marking designation. It includes the company's trademark, date of issue, information about the components. If there is no marking, then this is the basis for suspicion of the dubious origin of the goods.

- Integrity and transparency of the glass surface. During inspection, chips and cracks, etc., should not be detected. Condensation cannot accumulate inside the bag.

- Sealing quality: it assumes that the distance frame is free of traces and fragments of mastic, and the upper polymer layer applied along the outer perimeter of the glass block is homogeneous, without bumps and cracks. If the sealing is carried out carelessly, it is better to refuse the purchase.

- Compliance with proportions and dimensions. It is necessary to measure the glasses diagonally with a tape measure, and if the lengths differ by 3 millimeters or more, then the geometry of the block is not consistent. With a caliper, you can measure the thickness of the block at different points, the maximum allowable deviation is 1 millimeter.

Attentiveness and a couple of elementary measuring tools will help determine how high-quality the window is. If any of the listed signs of dishonest work are found, the product cannot be bought, even if its price is low.

Number of sealing circuits

One of the main advantages of metal-plastic window systems over traditional wooden ones is tightness. To achieve it and maintain it throughout the entire period of operation, sealing contours are used that do not let cold air in in winter and moisture in summer, and keep the room warm. They also contribute to achieving a given level of sound insulation.

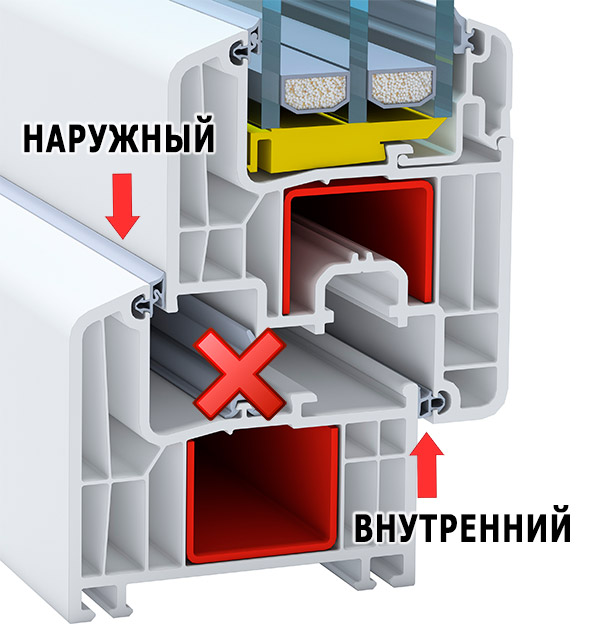

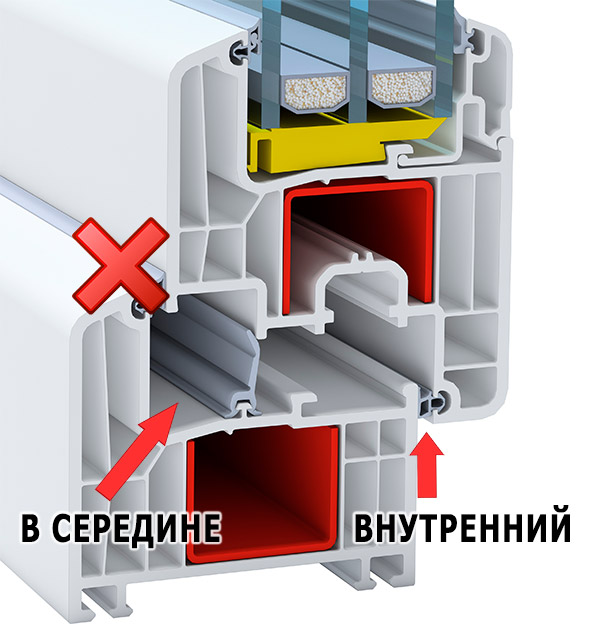

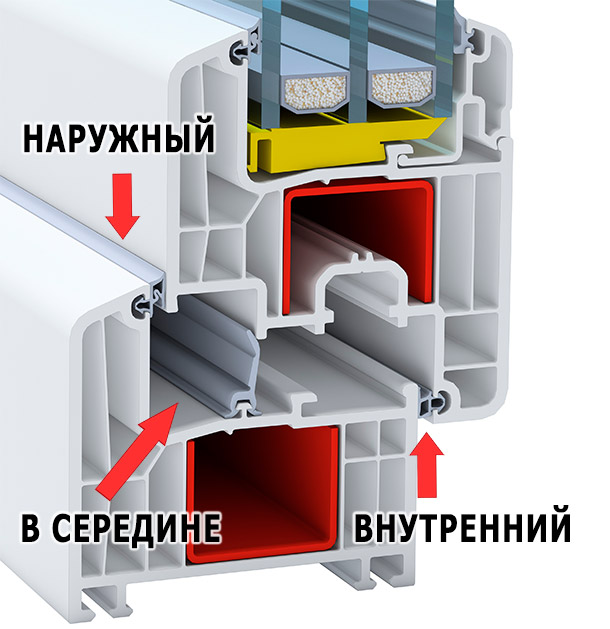

The seal is pressed into the grooves of the profile along the entire perimeter. There are models with two as well as three sealing circuits. The first option: one circuit is mounted on the street side, the other - in the apartment along the perimeter of the wings. The second option: one more row of a sealing element is added to the two indicated, the third contour is laid in the middle of the fold of the sashes. Models of the second option, of course, are more expensive.

According to the location of the sealing contours, plastic windows are divided into three categories:

- One inside, one outside. This type is the most popular, most companies stop at it. The internal element retains the declared properties longer, since it is not subject to the destructive effects of the environment. The outer element gradually loses its integrity and original properties, moisture penetrates inside the window unit. However, due to the specific geometry of the window, water is removed through holes in the profile. Disadvantages: if the external seal loses the declared qualities, the thermal insulation properties of the entire system are significantly reduced. Due to the penetration of moisture, the fittings rust and fail.

- One inside, the second in the middle of a fold of shutters. A more reliable option than the previous one. The outdoor element is located outside the zone of direct exposure to the environment, so it retains its properties longer. The specifics of its location protects the fittings from the ingress of water, which is discharged through drainage systems. Another advantage of this option: the wind presses the outer element against the stop, increasing the tightness of the system.

- One inside, the second in the middle of the fold of the wings, the third outside. The middle element forms a pair of air chambers, in the first one moisture is collected and removed, in the other there is fittings that do not get water.

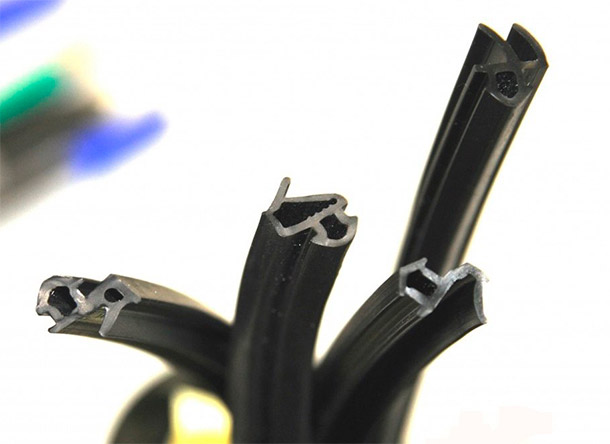

Types of sealant, requirements for it

Basic requirements for sealing material: strength, elasticity, preservation of the declared properties during thermal changes, safety for health, color fastness throughout the entire period of operation.

The most common types of seals are:

- Thermoplastic (TPE). Advantages: change shape when compressed, suitable for automatic assembly of a window unit, easy to weld, inexpensive, can be replaced by the user without special skills. Disadvantages: at extreme temperatures, and constant exposure to the sun's rays, they quickly deteriorate.

- Silicone. Advantages: wear resistance, are not afraid of extreme temperatures and environmental influences. Disadvantages: high cost, not always available in retail.

- Ethylene propylene rubber (EPDM) samples. Advantages: wear resistance, not afraid of extreme temperatures and environmental influences, cheaper than a silicone sealant. Disadvantages: for replacement, you need to call a specialist.

- Rubber. Advantages: the same as silicone or EPDM, plus - low price and the possibility of self-replacement. Disadvantages: under extreme temperatures and constant exposure to the sun's rays are destroyed.

- Shlegel Q-Lon Foam Samples. Advantages: they quickly restore their shape after compression, they are not afraid of extreme temperatures, as well as environmental influences, a high level of thermal and sound insulation, they retain color throughout the entire period of operation. Disadvantages: in case of violation of the integrity of the shell, they lose their properties, a specialist must be called for replacement, high cost.

In order for the sealing material to serve as long as possible, it should be cleaned and lubricated a couple of times a year (before summer and winter). To do this, do not use solvents, it is better to wash the sealant with water with a neutral detergent composition. When it dries, lubricate with glycerin or silicone oil.

Glazing beads: purpose, types

The function of glazing beads in metal-plastic windows is to fix the glass block in the frame. In addition, this detail contributes to a high level of sealing, as well as thermal and sound insulation of the entire window system. A groove is provided for its installation in the profile. A glazing bead is a long rail made of polyvinyl chloride, equipped with a rubber seal. Over time, it wears out, and glazing beads have to be changed. This process is simple and does not require special skills. In order not to violate the style of the window block, the new slats must match the frame in color.

The described components are classified according to the shape of the profile section: it can be square, round, curly. For window systems with one chamber, wide glazing beads are used, with three - narrow, with four - reinforced. In stores, you can find the described parts not only from polyvinyl chloride, but also from glass composite, which are identical in properties to their PVC counterparts.

Accessories: characteristics, types, popular brands

Such important parameters of the window system as thermal and sound insulation, light transmission depend on the frame and the glass block. accessories performs no less important functions, the comfort of using the entire system, the service life depends on its quality. Fittings are not only a set of devices (hinges, latches, handles), but also a well-coordinated mechanism responsible for opening and closing the doors in all positions, air exchange, and sealing.

Fittings are mounted around the entire perimeter of the frame. Its main types:

- Turning. Similar to the mechanism used in wooden window systems, the sashes rotate around axes in a vertical plane.

- Sliding. The frame is displaced in the plane of the opening. Such mechanism is expedient in window systems of the big area, at a glazing of balconies, loggias.

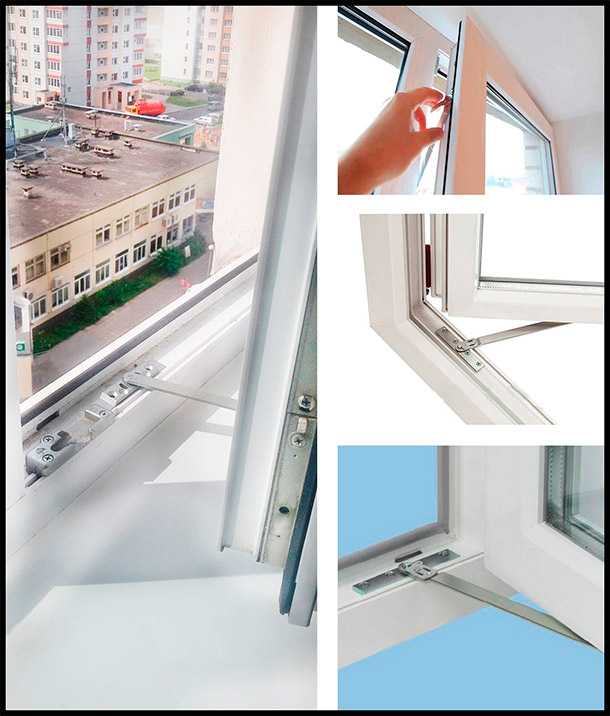

- Folding. The rotation of the wings is possible along the horizontal axes, the angle of rotation is 180 degrees. To comply with this parameter, a special limiter is set. Transoms can be folded up and down.

- Universal. The most complex sample: the sashes rotate around the axes in the vertical plane, and also recline along the horizontal axes with fixation of the lower edge. One of the options is selected by moving the handle to a predetermined position.

The allowable design load on the fittings is from 50 to 135 kilograms. This is enough for window blocks installed in many apartments. The usual, relatively inexpensive equipment, which is installed in most popular windows, should theoretically work out 10 thousand consecutive manipulations (closing, opening, ventilation mode, etc.) without interruption. Expensive mechanisms produced by well-known brands are designed for 50,000 consecutive actions. All fittings must be made of alloy steel. The use of less durable metals is allowed only for components that are not under load. The use of plastic in the mechanism is unacceptable.

If these rules are not followed, then there is no doubt that such accessories are a base fake.

The most famous profile companies are: Siegenia-Aubi, Maco, Winkhaus, Roto, GU (Gretsch-Unitas).

Detailed article on the topic: What fittings are best for plastic windows: reviews, rating

Hardware accessories

The described mechanism consists of many devices and parts that provide ease of use of the window system, here are the main ones:

- strikers. They are installed along the inside of the frame perimeter, purpose: to ensure tight closing of the sash. The minimum number of these parts is four units. If there are fewer of them, then the tightness will be broken, the thermal insulation properties of the window will decrease.

- blocking device. The device protects the mechanism from breakage due to incorrect actions, contributes to a high level of safety in using the window block. You can check its presence as follows: move the open sash with a handle to the folding position, if at the same time the transom hangs only on the lower hinges - there is no blocking device.

- loops. There are the following: hidden (opening angle 100 degrees), screw-in (mounted on threaded pins), overhead. Overhead type parts are collapsible, non-collapsible, tilt-and-turn, rotary, increased security (against burglary). In the fitting mechanism, the loops are conditionally divided into samples of the lower or upper group.

- handles. High-quality models are made of aluminum alloy or brass, covered with plastic on the outside. Cheap plastic ones break quickly. There are handles of increased security (against burglary), they are equipped with a locking device that prevents the sash from opening from the outside. The shape is divided into curly and flat. The products of the brands Roto, Maco are of the highest quality.

- Angular switches. These nodes provide displacement of the locking device in the corners, turning the sash into a tilt-and-turn state, and consist of steel plates.

- Locking pins. These fittings protect the window block from unauthorized opening. The trunnions are installed together with the slats (reciprocal, locking), do not need adjustments (automatically adjusted depending on the backlash of the fold), ensure smooth operation of the locking device.

- lock fittings. These elements should provide all manipulations with the window (closing, opening, tilting). There are three types: basic, intermediate, auxiliary. Auxiliary ones are located near the hinges, they are responsible for the tight porch of the frame. The main ones depend on the type of fittings mechanism. Auxiliary, as a rule, these are various anti-burglary locks.

If, when using the window system, a backlash appears in the operation of the locking fittings or, conversely, the movement of the mechanism is difficult, then it needs to be adjusted. In the absence of a special skill, it is better to call a specialist for adjustment.

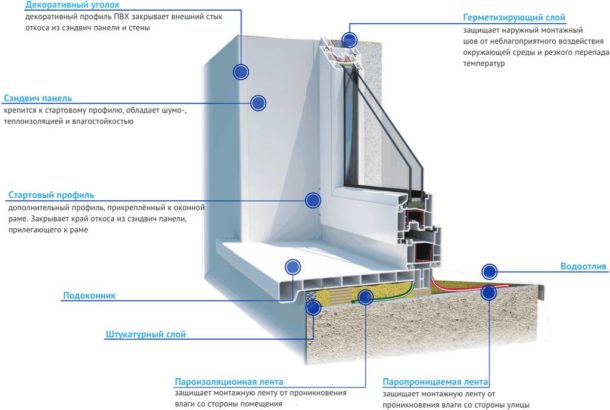

Slopes and tides

Window block installation completes slope finishing. These are fragments of the opening framing the window around the perimeter from the side of the street and the apartment. Their decoration plays a rational and aesthetic role.

- Rational: the level of thermal insulation increases, as well as the service life of the entire system.

- Aesthetic: A sloping window looks beautiful.

Detailed article on the topic:What is the best way to finish the slopes of plastic windows?

There are several finishing options: plaster, drywall, plastic sandwich panels. Slope plaster is used, as a rule, in public or industrial buildings. Advantages: wear resistance, versatility, simplicity of the process, low price. The main disadvantage: low level of thermal insulation.

Plasterboard slopes are in demand, which is laid on a layer of heat-insulating material, then the surface is primed, covered with a building compound, and painted. The advantages of this finish include a high level of thermal insulation, long service life. Disadvantages: complex long installation, the possibility of application only from the side of the room.

The most rational option for processing slopes is the installation of plastic sandwich panels. This building material repels moisture, is impervious to steam, has a high level of thermal insulation, and does not develop fungus or mold. It is also possible to add fast simple installation, universality, the long period of service to advantages. There is only one drawback: the relatively high cost.

The joints of adjacent slopes should be sealed with liquid plastic, which is similar in composition to PVC, while the integrity and shape of the butt joints are not violated for the entire period of operation. It is impossible to use silicone for these purposes, since it will not protect the slopes from mold, after a few weeks the integrity of the seams will be broken, you will have to redo everything.

The ebb is mounted in the lower part of the opening from the side of the street, it is a sheet with a curved edge, made of plastic or iron, of different dimensions. In addition to the decorative purpose, this finishing detail protects the wall, as well as the window from the effects of the external environment, removes melt or rain water.

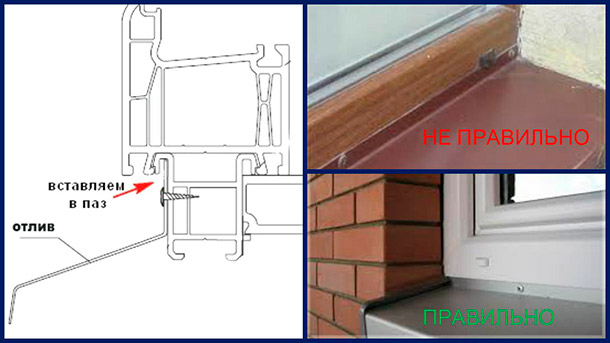

In order for the ebb to perform the listed tasks, it is important to follow the installation rules:

- The sheet is installed at an angle towards the street.

- The ebb is inserted into the groove under the window and screwed to the support profile, but not to the front of the window!

- There should be no gaps between it and the wall.

Most often, the ebb is made of thin (thickness from 0.5 to 1 mm) rolled steel. The workpiece is covered with layers of white zinc, polymer, varnish, this contributes to a long period of operation. The dimensions of the workpiece depend on the window opening, the standard width (overhang) is 14, 18, 25, 45 centimeters.

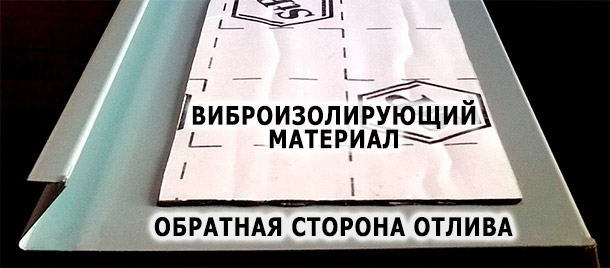

For sound insulation of the ebb, its reverse (lower) side is pasted over with a layer of material that absorbs vibrations. And the ebb itself is additionally glued to the mounting foam.

Additional features of PVC windows

The popularity of plastic window systems is explained not only by their characteristics and stylish appearance, but also by their versatility. The main functions have already been described in this article, we list some additional ones:

- Mosquito sections. It is a plastic frame with a polyester mesh of different throughput. Purpose: when the window sashes are open, to prevent the penetration of insects, fluff, dust into the room. It is fixed in the frame on special mounting brackets or pressed with metal brackets.

There are also grids on magnets, Velcro and rolled. The latter are very comfortable, do not require removal, just lift them up like roller blinds. Minus - high price and difficulty in maintaining cleanliness. Frame mosquito nets can always be easily removed, washed and placed on the balcony or in the pantry.

- For cat owners, there are samples with a reinforced mesh that retains its integrity after contact with the claws of the animal.

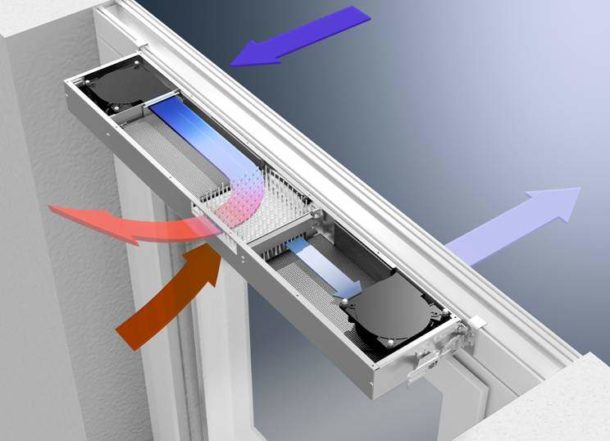

- Vent valve. Mounted in the upper sector of the window profile, purpose: automatic air exchange that does not require the opening of the sashes.Advantages: the ability to adjust the air exchange rate, the device is easy to clean with a vacuum cleaner, there is no noise during operation, it does not need to be connected to an electric current network. There are models (recuperators) that, due to the design features, use the thermal energy of the exhaust air mass to heat the supply air.

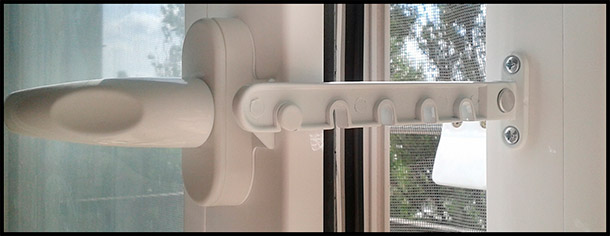

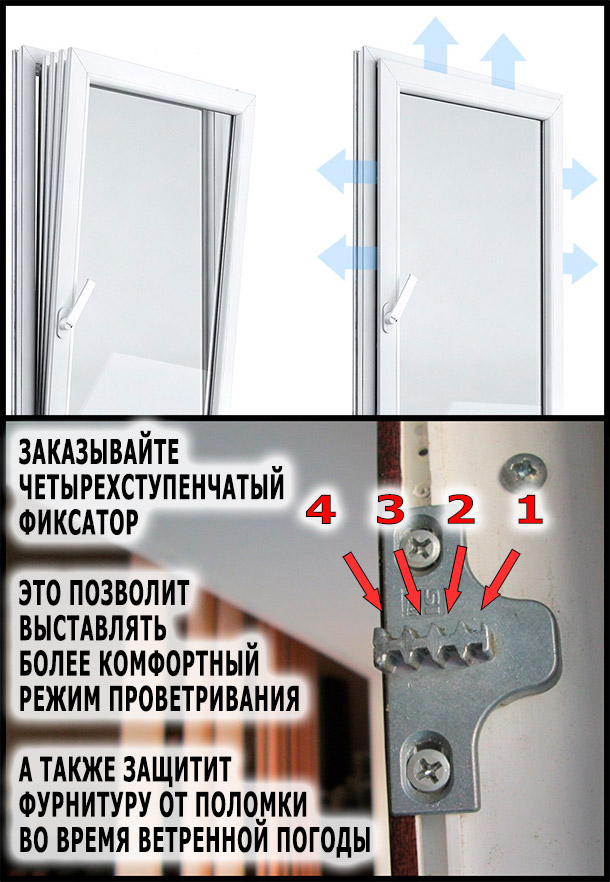

- Devices for adjustable air exchange: comb, rotation limiter, latch for stepped inclination of the sash. The restrictive comb is designed to fix the window sash, while ensuring the ventilation of the room in the specified mode. The width of the gap between the sash and the frame is from 1 to 7 centimeters. The comb will prevent small children or pets from opening the window wider, which is an additional safety measure.

- The rotation limiter fixes the sash at a distance of 6 to 8 centimeters from the frame, such a gap is enough for the influx of fresh air mass. The latch for the stepped tilt of the sash works in the same way.

- Slit ventilation. Air exchange mode, in which the flow of air from the street occurs through a gap (width 4-5 millimeters) in the upper sector of the window. The gap is formed when the handle is turned 45 degrees up.

- This function is also called "winter ventilation", as it does not create drafts and significant heat loss.

- Child protection. Child locks do not allow the baby to open the sash wider. Most often, devices are used that block the rotation of transoms; The handles are removable and lockable.

Companies producing plastic translucent systems are constantly improving their design, so the number of additional options will increase.

Window sills for plastic windows

In addition to decorative window sills many practical uses. For example: a shelf for pots with vegetation, a place for a child to play, a sitting area for a cat, an additional countertop in the kitchen for storing utensils or household appliances. Profile companies produce samples from different materials, colors, dimensions. Window sills made of PVC, chipboard or MDF, stone (natural, artificial), wood are in demand.

- Stone are environmentally friendly, durable, withstand heavy loads. The disadvantages include significant cost and weight.

- Wooden window sills, again, are environmentally friendly, beautiful, pleasant to the touch. However, they have many disadvantages: rapid wear, high cost (especially if they are made of valuable wood), and are afraid of condensate.

- Options from MDF or chipboard are not exposed to moisture, temperature changes, ultraviolet radiation, and are cheap. Disadvantages: low level of strength, the presence of different chemical compositions (glue, resin, etc.).

- PVC window sills have almost no drawbacks, except for the fact that they are made of non-natural material. There are many advantages: they are not afraid of moisture, temperature changes, UV rays, cheap, durable, high level of thermal insulation, easy to clean. They withstand significant loads, the magnitude of which depends on the number of stiffeners.

Window sill installation - this is not the kind of work that can be done without special skills, tools and materials. For installation, you should hire specialists from a specialized company that has been working in this field for a long time. A competent master will observe all the nuances of the installation technology: a standard protrusion from 5 to 10 centimeters long, the angle of inclination of the window sill plane, etc. Such work requires the skill of using certain building mixtures, adhesives, mounting foam, hardware.

Variants of window systems models

The block may consist of one sash or several. There are four typical models of a metal-plastic window from which blocks are formed:

- Deaf. Opening sash is not provided, simple design, the cheapest sample. They are used in the corridors of public buildings or in rooms where openings are located too high.

- Swivel.The opening sash rotates around an axis in a vertical plane. There are no restrictions on the application, they can be used everywhere.

- Folding. The sash opens partially in the upper sector of the window, is at an angle to the plane of the frame. Are established in sanitary knots, bath rooms, entrances of apartment houses.

- Swing-out. The most convenient sample, the transom opens both in rotary and folding models, the option is selected by turning the handle. There are no restrictions on the application, they can be used everywhere.

The number of opening options in the block, as well as their type, depend on the characteristics of the room, one system may include fixed, pivoting, folding windows.

Production

Some companies that produce translucent PVC structures own a full production cycle, others assemble blocks from purchased components. The former include large firms that have been operating in the core market for a long time. Owning a full cycle, they control the quality of the product at all stages of its production. And also large companies invest significant money in innovative developments.

Using this business model, they produce the highest quality window systems in compliance with all norms and standards. The latter include beginners or firms that are initially focused only on assembly. Some try to keep production costs as low as possible by purchasing low-quality components.

Firms producing translucent PVC structures are required to have certificates of conformity, such as RAL and DIN EN ISO 9001:2000.

Both the brands themselves and third-party companies are engaged in the installation of metal-plastic windows.

PVC profile is made by extrusion, the raw materials include polyvinyl chloride granules, stabilizing and modifying elements, titanium oxide, dyes, etc. PVC granules are produced almost all over the world. PVC blanks are made on extruders. Before turning into a detail for a metal-plastic window, they are processed on many machines. Equipment is used: milling cutters, miter saws, drilling and reinforcing machines, clamps, welding machines, etc.

The impact of PVC windows on health and the environment

The development of global industry over the past 150 years has led to significant damage to the ecosystems of our planet. Therefore, the safety for health and nature of any product produced by the production method is one of the most important parameters. Polyvinyl chloride is an unnatural material obtained by chemical synthesis. However, it is not dangerous to health, this is confirmed by many independent examinations that were carried out by research centers around the world. Of particular concern were some additives that provide PVC preforms with the declared qualities, but new technologies completely neutralize the possible harmful effects of these additives.

Environmentalists were also concerned about the presence of lead in the profile and the adhesive composition that was used to attach the laminating film. In older models, lead was used to prevent the loss of the original color of the blanks, in addition, these were passive type lead compounds that do not pose a threat to the environment. Lead is no longer in the new models, it has been replaced by zinc and calcium compounds. They also use a safe polyurethane adhesive.

The problem of recycling plastic is acute, but it mainly concerns plastic containers and packaging. There are two methods for the disposal of used PVC profile.

- First: its use as an unconventional raw material for generating electrical energy (pyrolysis method). The specificity of the process excludes toxic emissions into the surrounding ecosystem.

- Second: processing of the old profile for raw materials for a new one. Translucent PVC structures are designed for half a century of service, so gradually there will be more methods for their effective processing.

Summarizing the above facts, we can conclude: metal-plastic windows are safe.

Installation Recommendations

The quality and long period of uninterrupted operation of the window system depend on two components: the properties of the window itself and compliance with the installation technology. The stores offer to buy products from the EU, China, Turkey, the best plastic windows are made by well-known European companies, especially German ones. European counterparts are more expensive than others, but not dramatically, such windows, subject to the rules of operation, will last 40-50 years.

If it is not possible to order installation services from a European manufacturer, then you should choose a third-party contractor with a good reputation. Information of this kind is available on the Internet, you can easily find out: how long this company has been working, what are the reviews of customers, what guarantees apply to, etc. It is better not to contact a contractor who is little known or offers too low prices. Even if the installation is done by a reputable company, it is still worth monitoring the progress of work.

Installers should use a special construction foam (eg "Tytan"). To dry and protect the foam layer from ultraviolet radiation, a special sealing tape (PSUL) must be used. It is hidden from the sun's rays by external slopes or flashings.

Read a detailed article on the topic:Which foam is best for plastic windows?

Which windows are better to put in the apartment (by room)

Here are some more tips for installing different window systems in the rooms of an apartment for various purposes (recommendations are designed for the average European climate):

- For the living room, a four- or five-chamber profile with a glass block with one or two chambers is suitable. It will be enough to fill the chambers with air, it is not necessary to overpay for models with inert gas. You can also refuse energy-efficient glasses.

- The office has to be ventilated frequently, and sound insulation is also important for the workplace. Therefore, a profile with five chambers is suitable for it, a glass block with two or three. Due to frequent ventilation, a high-quality fitting mechanism is important.

- It should be warm in the children's room and bedroom, the same windows as in the office will do, but you can choose models with inert gas in double-glazed windows and energy-efficient glasses.

- In the kitchen, a high level of sound or thermal insulation is not necessary, so a profile with three chambers is suitable for it, a glass block with one or two. Due to frequent ventilation, a high-quality fitting mechanism is required, you can also install a ventilation valve.

Features of winter installation, construction debris removal

There is an opinion that window replacement should be carried out only in spring or summer, but this is nothing more than a myth. Replacement is also possible in winter, it just has a number of features, although there are still temperature restrictions.

- The minimum temperature at which it is allowed to carry out such work is 15 degrees below zero. At lower values, the mounting foam loses its properties, rubber sealing materials are tanned, as a result of which it is impossible to adjust the sashes.

- The window block cannot be installed “from wheels”, it should be brought into the apartment a day before installation, this will eliminate thermal deformation of the window components.

- When replacing, sealing foam compounds of a special frost-resistant type are used.

- It is imperative that among the equipment there should be a “heat gun”, which is used to heat joints with foam from the outside, waterproofing tapes, as well as PSUL. In order not to cool the room, a heat shield can be used during installation.

It is impossible to expose old windows and bags with construction waste to garbage cans in the yard, you can get a fine for this.

Garbage, together with the dismantled frames, should be taken to the municipal waste landfill. When concluding an agreement with a company, it is better to include this item in the mandatory list of works by paying for it. All major contractors provide similar services. An alternative is to call a small company that specializes in transportation, they usually provide such services.

Rating of plastic windows by quality in 2021

What plastic window systems are better to install? The answer to this question depends on the taste, financial capabilities, the specifics of the location of the apartment or house.

Here are the most popular brands that are of high quality:

Editor's Choice: VEKA, REHAU and KBE. These are the most common and time-tested profile manufacturers!

- VEKA (Germany). About half a century of work. Models: SOFTLINE, SWIGLINE, EUROLINE, ALPHLINE, SOFTLINE 82, PROLINE. Price: about 10,000 rubles.

- REHAU (Germany). 70 years of work. Models: SIB-DESIGN, INTELIO, BLITZ, GENEO, BRILLANT-DESIGN, EURO-DESIGN. Advantages: high quality, large assortment. Disadvantages: significant cost. Price: about 10,000 rubles.

- KBE (Germany). Almost 40 years of work. Models: KVE SELECT, KVE 88, KVE ENERGY, KVE EXPERT, KVE EXPERT PLUS. Advantages: high quality, large selection, relatively low price. Price: about 7500 rubles.

- SALAMANDER (Germany). 45 years of work. Models: Design 2D, Streamline, Design 3D. Advantages: high quality, original appearance. Disadvantages: significant cost. Price: about 15,000 rubles.

- MONTBLANC (Germany). 13 years of work. Models: LOGIC, QUADRO 70, CITY 120, TERMO 60, ECO Advantages: high quality, low price. Disadvantages: products are not certified in the post-Soviet space. Price: about 7500 rubles.

- KALEVA (Russia). 20 years of work. Models: Kaleva Design, Kaleva Vita, Kaleva Standart, Kaleva Deco. Advantages: high quality, original appearance. Disadvantages: significant cost. Price: about 10,000 rubles.

- PROPLEX (Russia). Almost 20 years of work. Models: PROPLEX-Premium, PROPLEX-Optima, PROPLEX-Lux, PROPLEX-Comfort. Advantages: low price. Cons: Some models are outdated. Price: about 8500 rubles.

- DECEUNINCK (Belgium). 20 years of work. Models: FORWARD, FAVORITE, EFORTE, FAVORITE SPACE. Pros: high quality. Disadvantages: some models are outdated, high price. Price: about 10500 rubles.

- TROCAL (Germany). 60 years of work. Models: InnoWave, InnoNova 70А5, Balance. Pros: high quality. Disadvantages: high price. Price: about 10,000 rubles.

- ALUPLAST (Germany). 40 years of work. Models: IDEAL 2000, IDEAL 4000, IDEAL 7000, IDEAL Advantages: wide choice, high quality. Disadvantages: high price. Price: about 10,000 rubles.

- SOK (Russia). Almost 15 years of work. Models: SOK-570, SOK-470. Pros: high quality. Disadvantages: incomplete production cycle, small assortment, high price. Price: about 12,000 rubles.

- SCHUCO (Germany). 30 years of work. Models: Schuco AWS 65 BS, Schuco AWS 112 IC, Schuco AWS 90 SI. Pros: high quality. Disadvantages: high price. Price: about 10,000 rubles.

- LG Chem (South Korea). 35 years of work. Models: L 600, L 700. Advantages: high quality, stylish look. Disadvantages: high price. Price: about 15,000 rubles.

- WDS (Ukraine). 15 years of work. Models: WDS 8 Series, WDS 7 Series, WDS 400, WDS Advantages: good quality, adaptation to the post-Soviet market, low price. Disadvantages: some models darken PVC over time. Price: about 7000 rubles.

- PANORAMA (Russia). 15 years of work. Models: Standard, Standard Plus, Premium. Pros: good quality, low price. Disadvantages: incomplete production cycle, small assortment. Price: about 7500 rubles.

- EXPROF (Russia). 17 years of work. Models: EXPROF AeroTherma, EXPROF Profecta, EXPROF Suprema, EXPROF Profecta Plus. Advantages: good quality, large selection, low price. Disadvantages: some models darken PVC over time. Price: about 7500 rubles.

- GEALAN (Germany). About half a century of work. Models: Gealan S 9000, Gealan S 8000 IQ, Gealan S 3000, Gealan FUTURA. Advantages: high quality profile and fittings, large assortment. Disadvantages: significant cost. Price: about 12,000 rubles.

- BRUSBOX (Russia). 15 years of work. Models: BRUSBOX Aero, BRUSBOX Super Aero. Pros: good quality, low price. Cons: small selection. Price: about 8000 rubles.

- WINTECH (Turkey). 20 years of work. Models: Thermotech 752, Poletech W80, Isotech 532. Advantages: good quality. Disadvantages: high cost. Price: about 10,000 rubles.

Prices are indicated for window systems with three sashes, prices may vary for different retailers.